Textile processing textile cloth fully soaked in bleaching and dyeing device

A textile fabric, bleaching and dyeing technology, applied in the field of textile processing, can solve the problems of color imbalance and insufficient dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

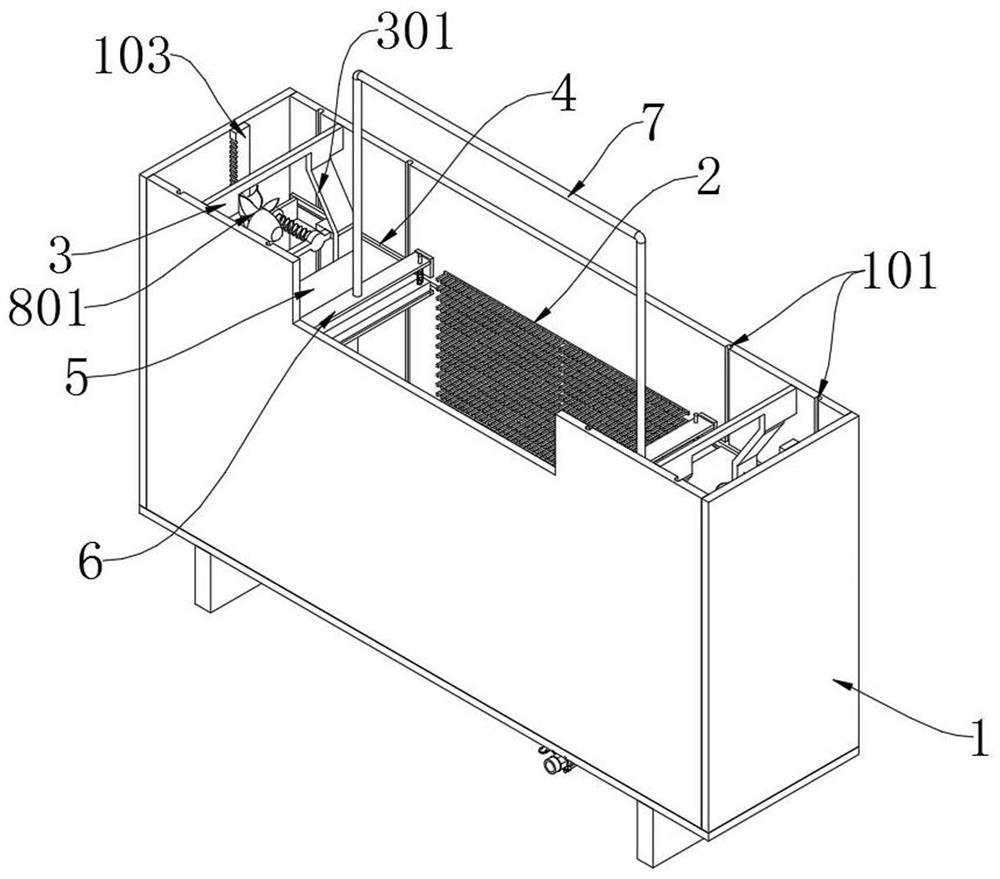

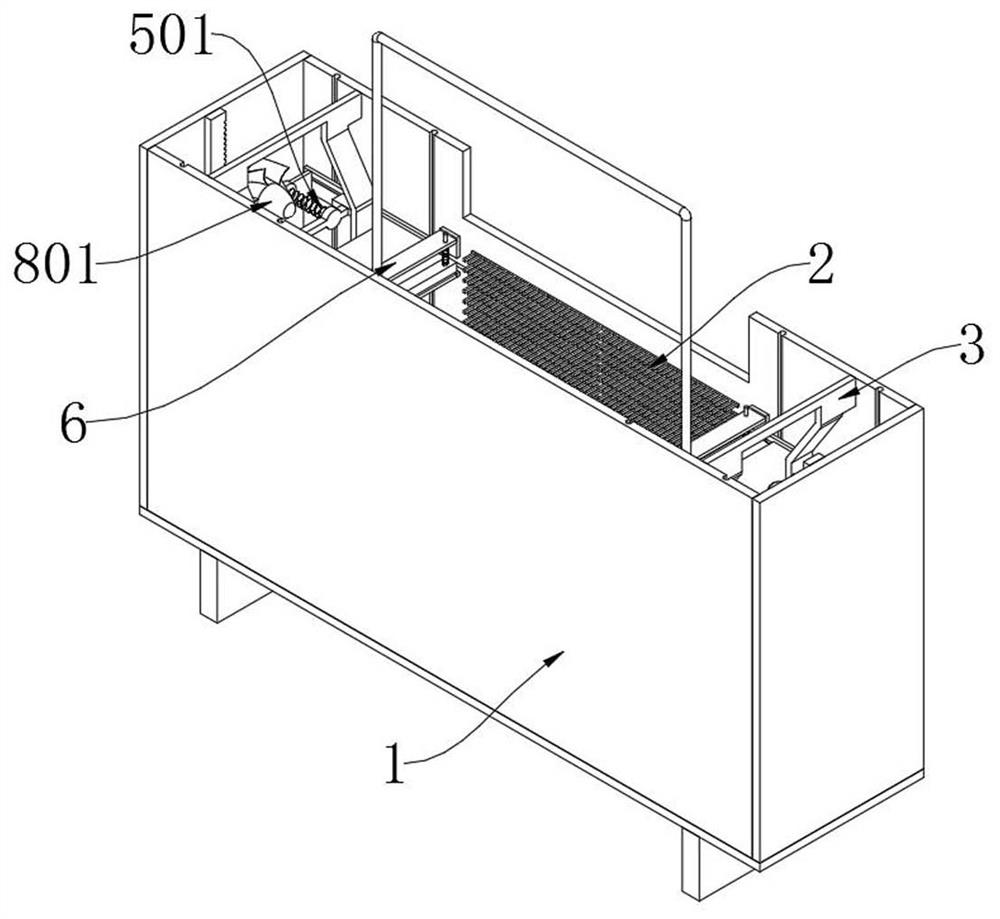

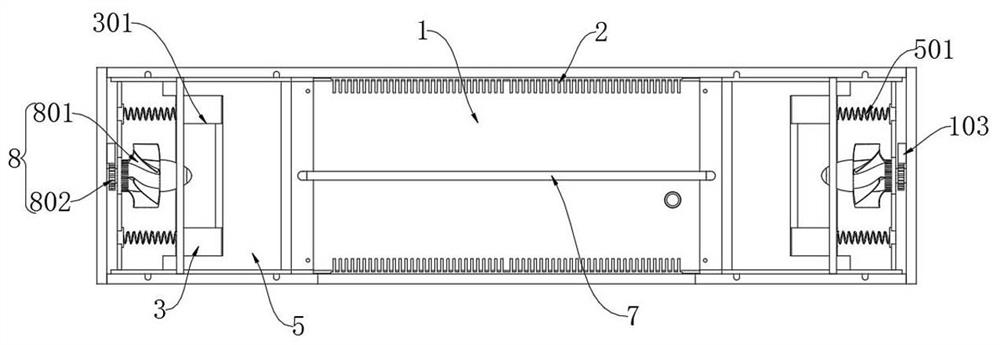

[0042] as attached figure 1 to attach Figure 8 Shown:

[0043]The invention provides a bleaching and dyeing device for fully soaking textile fabrics for textile processing, including a bleaching and dyeing box 1; the bleaching and dyeing box 1 is a cuboid box-shaped structure, the opening of the bleaching and dyeing box 1 is upward, and a rectangular gap is opened in the middle of the upper end of the front side wall of the bleaching and dyeing box 1. The bottom of the box 1 is equipped with a vent pipe; the front side wall and the rear side wall of the inner cavity of the bleaching and dyeing box 1 are respectively fixed with a transverse rhythm belt 2; two guide plates 3 are vertically fixed and installed on the bottom of the inner cavity of the bleaching and dyeing box 1 At the left and right ends of the plane, the side walls at the front and rear ends of the upper end of the guide plate 3 are fixedly connected with the front side wall and the rear end side wall of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com