Biomass gasification system with high gasification rate

A gasification system and biomass technology, which is applied in the field of biomass gasification system with high gasification rate, can solve the problems of insufficient contact between raw materials and catalysts, reduced purifying effect of combustible gas, insufficient contact of combustible gas, etc. Reasonable, improve the gasification speed and gasification rate, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

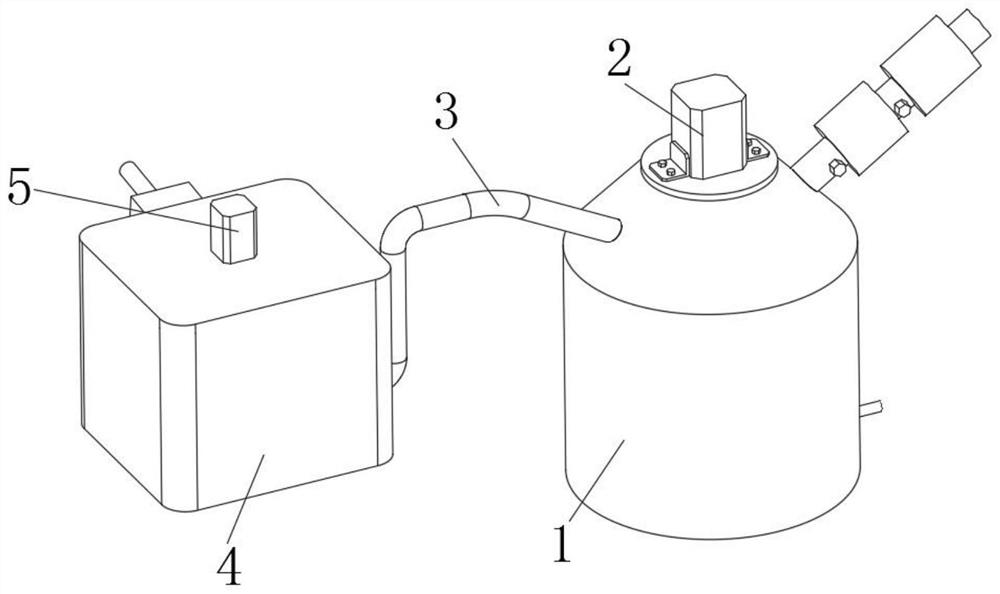

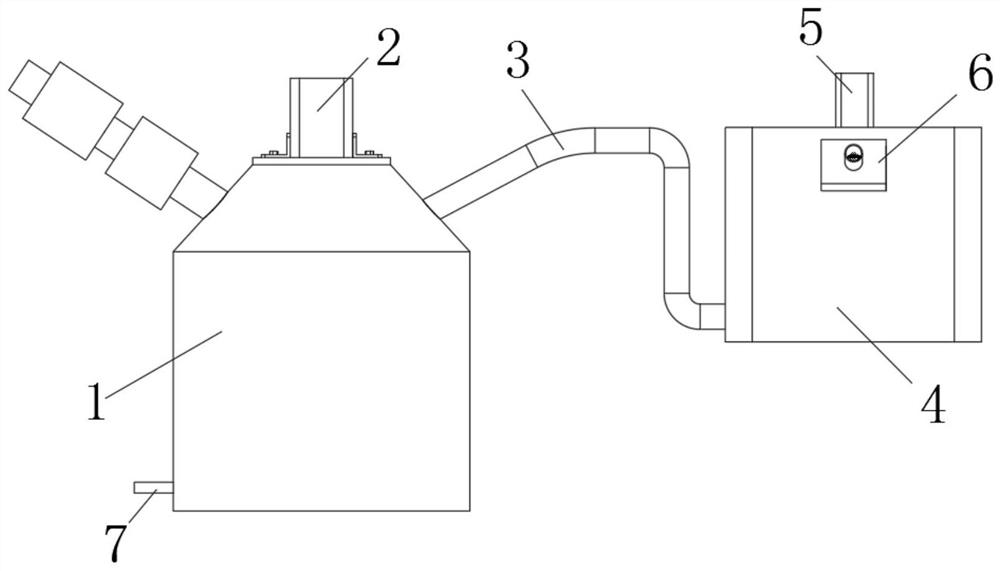

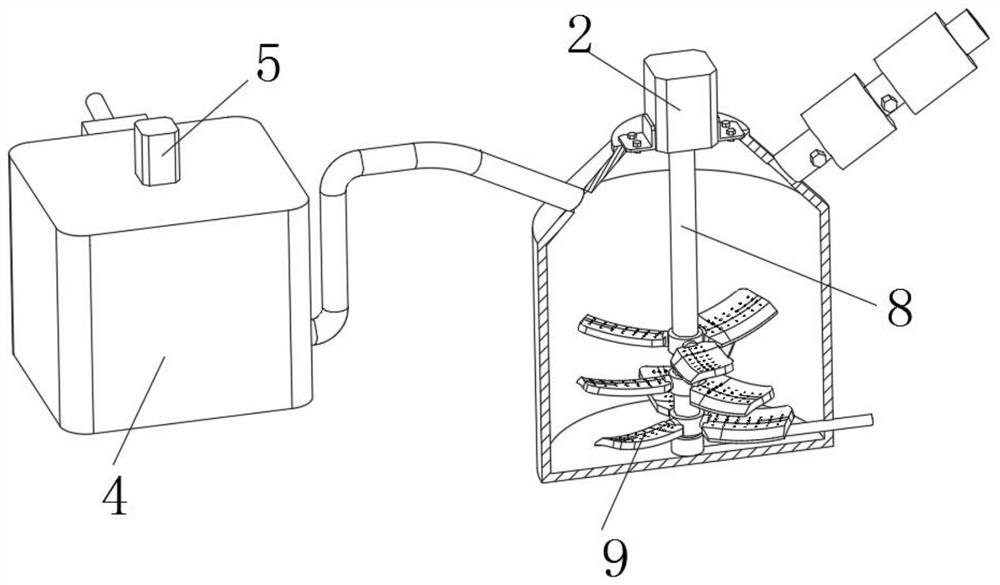

[0039] Example: Reference Figure 1-8 A high gasification rate biomass gasification system shown includes a gasification furnace 1, a first purification box 4 is arranged on one side of the gasification furnace 1, and the first purification box 4 and the gasification furnace 1 are connected through a connecting pipe 3 phase connection, the side wall of the first purification box 4 is fixedly connected with the second purification box 6 installed obliquely, and one side of the second purification box 6 is fixedly connected with the combustible gas collecting pipe connected to each other, and the gasification furnace 1 is set There is a dispersing and agitating part for biomass turning and stirring and catalytic liquid dispersing. The first purification box 4 is provided with a purification part for combustible gas purification. The purification part is connected with the second purification box 6 .

[0040] With the above-mentioned structure, by setting the dispersing and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com