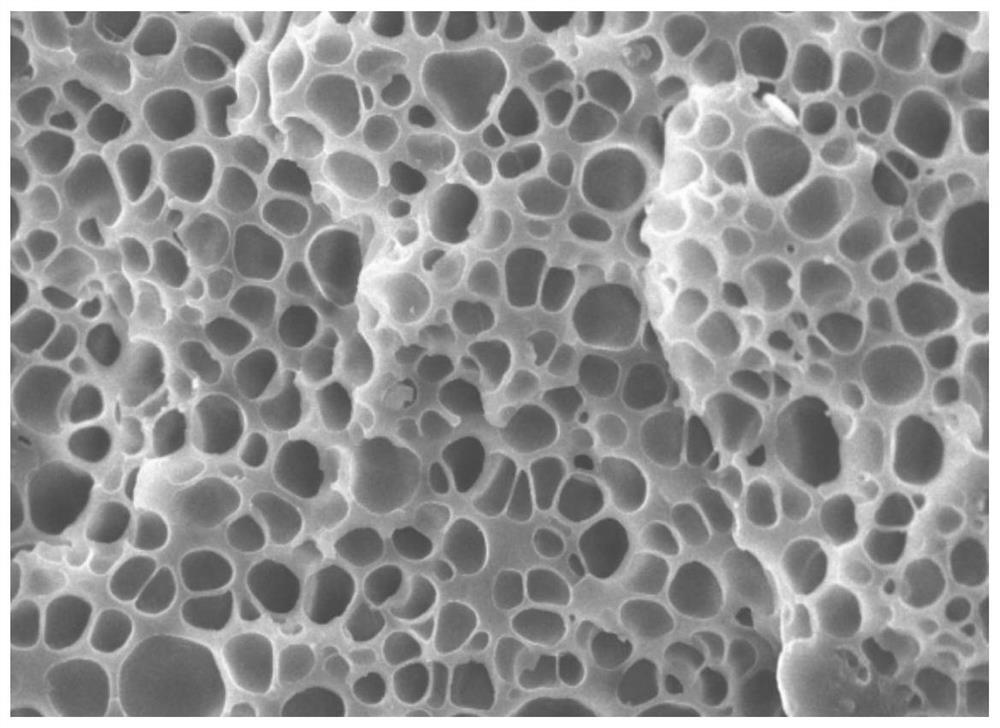

A kind of thermoplastic elastomer physical foaming coil and its semi-continuous preparation method

A thermoplastic elastomer and thermoplastic elastic technology, which is applied in the field of thermoplastic elastomer physical foaming coil and its semi-continuous preparation, can solve the limitation of large-scale preparation of TPU foaming film coil, TPU foaming process is unstable, and affects TPU Foaming behavior and other issues, to achieve the effect of large-scale continuous production, suppression of desorption phenomenon, low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiments of the semi-continuous preparation method of the thermoplastic elastomer physical foaming web of the present invention include the following steps:

[0064] (1) 100 parts of the TPU particles (Shaw's hardness of 80A), 5 parts of talc powder and 0.5 parts of antioxidants were sequentially dried, premixed, twin-screw continuous extrusion, calendering and retracted, and the thickness was 1 mm before Thermoplastic elastomeric coil;

[0065] (2) Place the step (1) before the previously driven plastic elastomer web filled with CO 2 In the high pressure container of the fluid, impregnate the impregnated thermoplastic elastomeric web having a high pressure fluid content of 9%, and then remove the impregnated thermoplastic elastomer web into the cooling chamber with liquid nitrogen by fast refrigeration lock gas treatment, at which time the temperature in the cooling cavity is -60 ° C, then low temperature at -20 ° C for 1 h, the temperature of the high pressure fluid in...

Embodiment 2

[0069] Embodiments of the semi-continuous preparation method of the thermoplastic elastomer physical foaming web of the present invention include the following steps:

[0070] (1) 100 parts of TPU particles (Shaw's hardness of 80A), 10 parts of EVA particles and 0.5 parts of antioxidants were sequentially dry, premixed, twin-screw continuous extrusion, calendering, and retracted, the thickness was 0.3mm. Formerly driven thermoplastic elastomerical coil;

[0071] (2) Place the step (1) before the previously driven plastic elastomer web filled with CO 2 In the high pressure container of the fluid, impregnate the impregnated thermoplastic elastomeric web having a high pressure fluid content of 9%, and then remove the impregnated thermoplastic elastomer web into the cooling chamber with liquid nitrogen by fast refrigeration lock gas treatment, at which time the temperature in the cooling cavity is -60 ° C, then low temperature at -20 ° C for 6 h, low temperature storage for 6 h after ...

Embodiment 3

[0075] Embodiments of the semi-continuous preparation method of the thermoplastic elastomer physical foaming web of the present invention include the following steps:

[0076] (1) 100 parts of TPEE particles (Shaw's hardness 85a), 0.5 parts of antioxidants are sequentially dried, premixed, twin-screw continuous extrusion, calendering, and retaining, the thickness is 0.5mm before driving a plastic elastic body roll material;

[0077] (2) Place the step (1) before the previously driven plastic elastomer web filled with CO 2 In the high pressure container of the fluid, impregnate the impregnated thermoplastic elastomeric web having a high pressure fluid content of 8.5%, and then remove the impregnated thermoplastic elastomer web into the cooling chamber with liquid nitrogen to perform a fast refrigeration lock gas treatment, at which time the temperature in the cooling cavity is -60 ° C, then at -20 ° C low temperature storage 24 h, a low temperature storage 24 h then impregnated the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com