Biodegradable milk tea bag making mechanism

A biodegradable and milk tea technology, which is applied in bag making operations, container manufacturing machinery, flexible container manufacturing, etc., can solve the problems of long production lines, affecting product quality, and pulling materials, so as to reduce unevenness, improve product quality, and reduce pulling. car deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

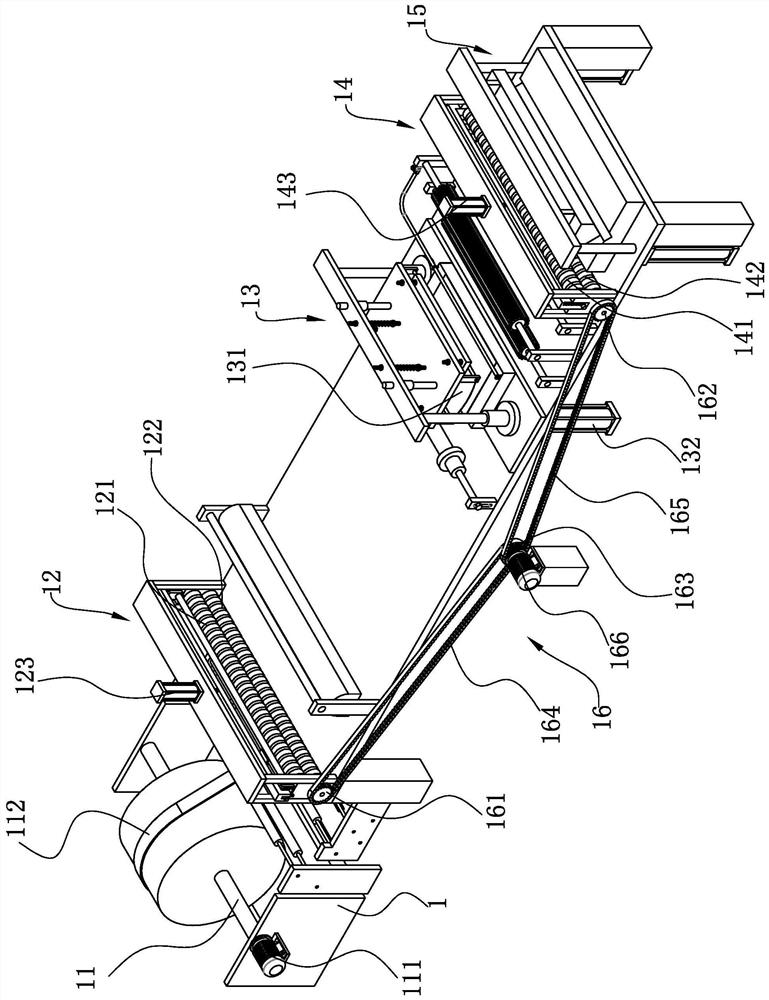

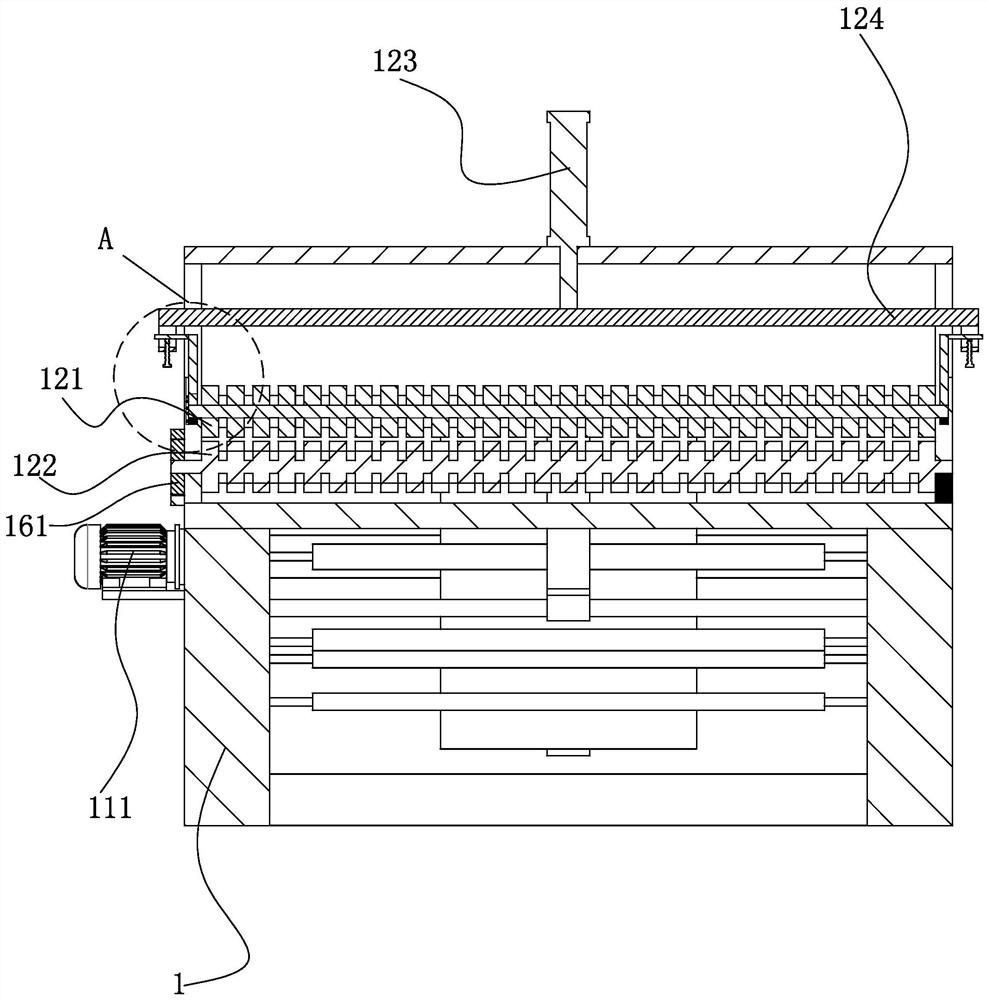

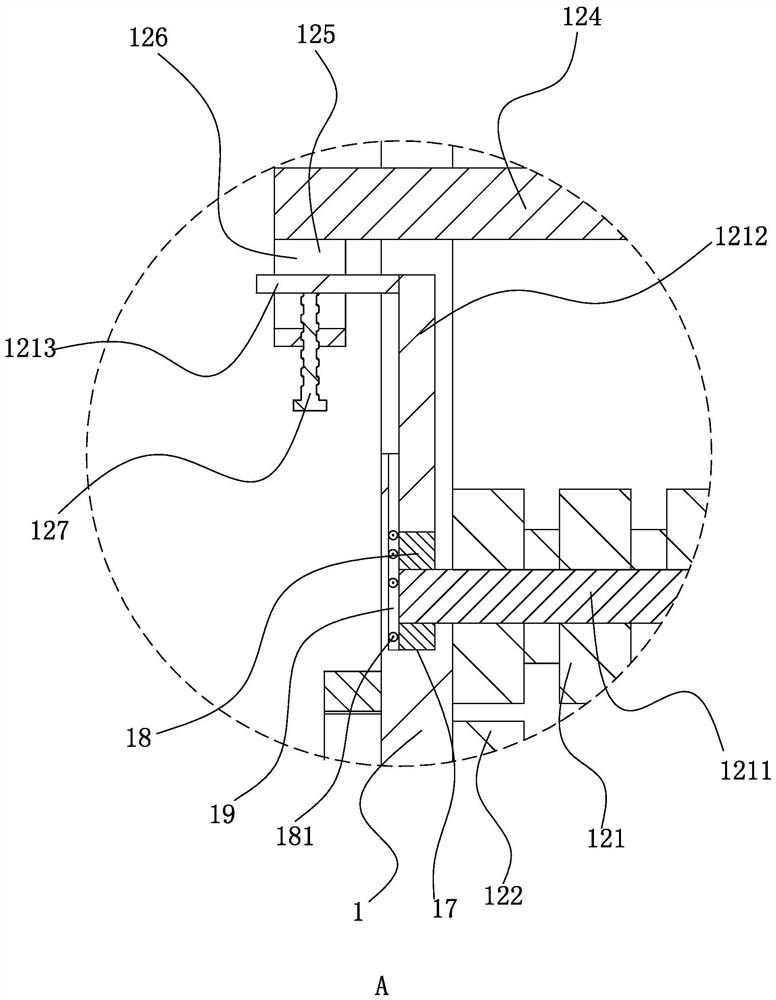

[0034] Below in conjunction with 1-3, the present application is described in further detail.

[0035] The embodiment of the present application discloses a biodegradable milk tea bag making mechanism. refer to figure 1 , the biodegradable milk tea bag making mechanism includes a frame 1, one end of the frame 1 is rotatably connected with a feed roller 11, a feed mechanism 12 is provided on the frame 1 near the feed roller 11, and a feed mechanism 12 and a pull mechanism 14 are arranged. There is a scalding device 13 between them, and the feeding mechanism 12 includes a cutting device 15 fixedly connected to the frame 1 at the end far away from the feed roller 11, and a pulling mechanism 14 at the end of the frame 1 close to the cutting device 15. . When in use, by placing the raw material coil on the feed roller 11, the discharge can be realized by the rotation of the feed roller 11, and the simultaneous discharge can be realized by setting the feeding mechanism 12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com