Hot molding machine

A thermoforming machine and molding die technology, applied in the field of thermoforming machines, can solve the problems of easily scalded operators, low work efficiency, and broken products, and achieve the effects of improving product yield, improving work efficiency, and enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

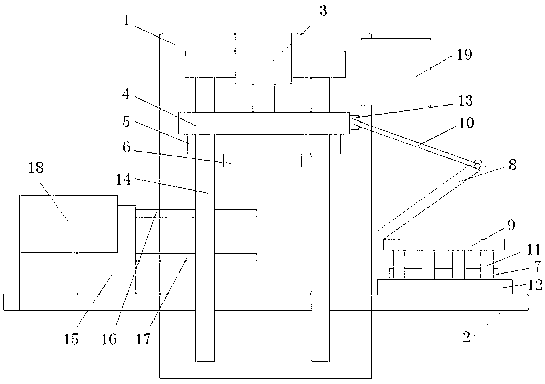

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a thermoforming machine includes a bracket 1, a workbench 2, a driving device 3, a pressing plate 4, an upper mold 5, a forming mold 6, a lower mold 7, an upper splint 8, a lower splint 9, a pull rod 10, a spring 11, Sliding plate 12, demoulding blowing device 13, sliding shaft 14, sliding frame 15, upper protective plate 16, lower protective plate 17, accommodation box 18 and instrument box 19.

[0018] A workbench 2 is arranged in the support 1, and the front side of the workbench 2 extends to the outside of the front side of the support 1. A driving device 3 is arranged on the inner wall of the top of the support 1, and a pressing plate 4 is arranged at the bottom of the driving device 3. On the side of the pressing plate 4 A patrix 5 is fixed below, a slide plate 12 capable of sliding horizontally is provided on the workbench 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com