Automatic polishing tool for machine barrel

An automatic polishing and barrel technology, which is used in grinding drives, surface-polishing machine tools, and grinding/polishing equipment to improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

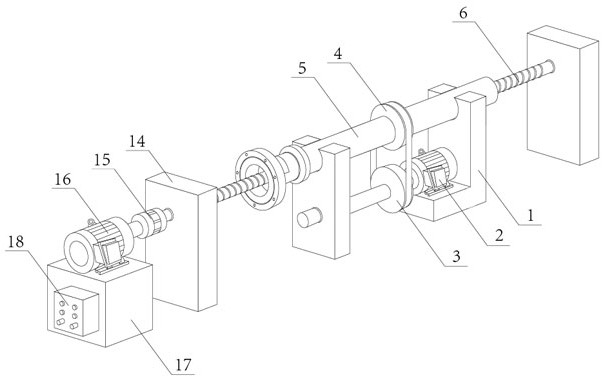

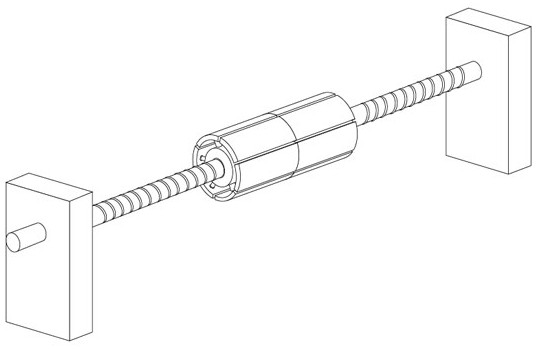

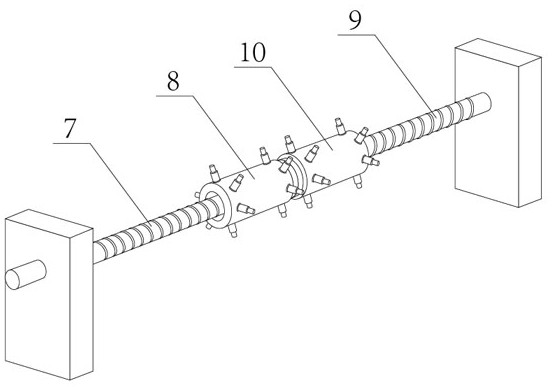

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Machine barrel automatic polishing tooling, including machine barrel support seat 1, machine barrel rotating motor 2, driving wheel 3, driven wheel 4, machine barrel 5, two-way screw 6, left-handed thread 7, first nut 8, right-handed thread 9, Second nut 10, automatic expansion rod 11, polishing bar 12, hole 13, screw support seat 14, shaft coupling 15, lead screw motor 16, motor support seat 17 and controller 18, on the barrel support seat 1 An organic barrel rotation motor 2 is installed to provide rotation. The shaft end of the barrel rotation motor 2 is connected to the driving wheel 3 for power transmission. The belt of the driving wheel 3 is connected to the driven wheel 4 for power transmission. The organic barrel is installed on the driven wheel 4 5. It is a processing part. There is a two-way screw 6 passing through the barrel 5 to provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com