Conductive silver paste and preparation method thereof

A technology of conductive silver paste and conductive filler, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of affecting the mechanical and electrical properties of nano-silver paste, affecting the connection of conductive paths, Solve problems such as conductive silver paste cracks, achieve the effect of improving floatability, increasing contact area, and promoting the completion of lap joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A electrically conductive silver paste comprising it consisting of a weight of the following weight: (a) 3 to 20 parts of the linear oligomer, (b) 20 parts of the conductive filler, (c) 1 part to 15 parts of other auxiliaries Also include a resin carrier;

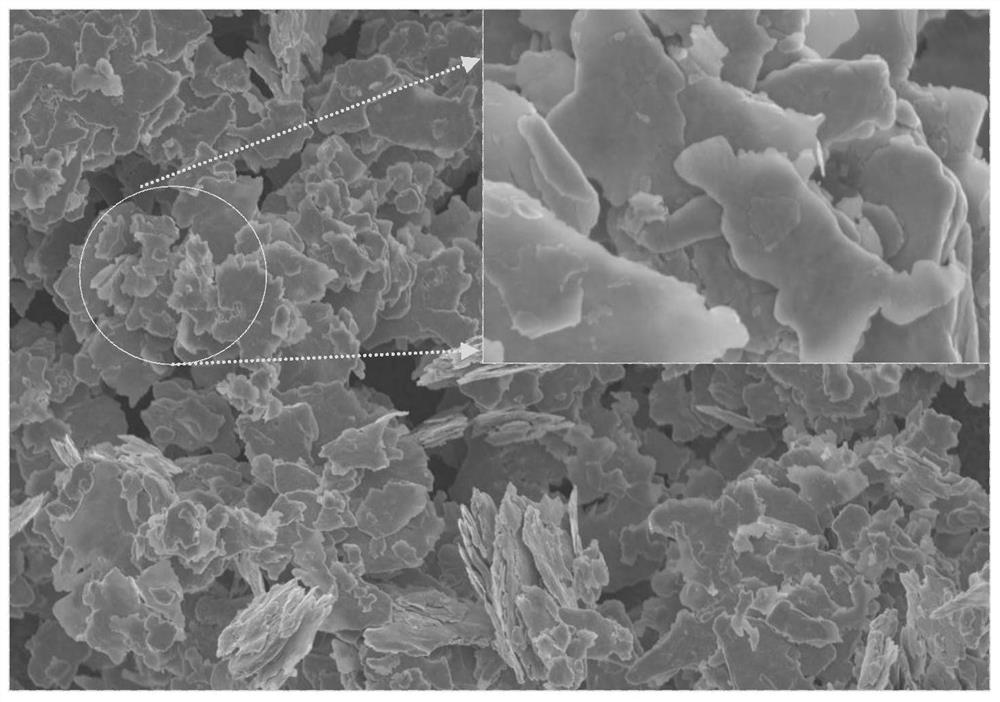

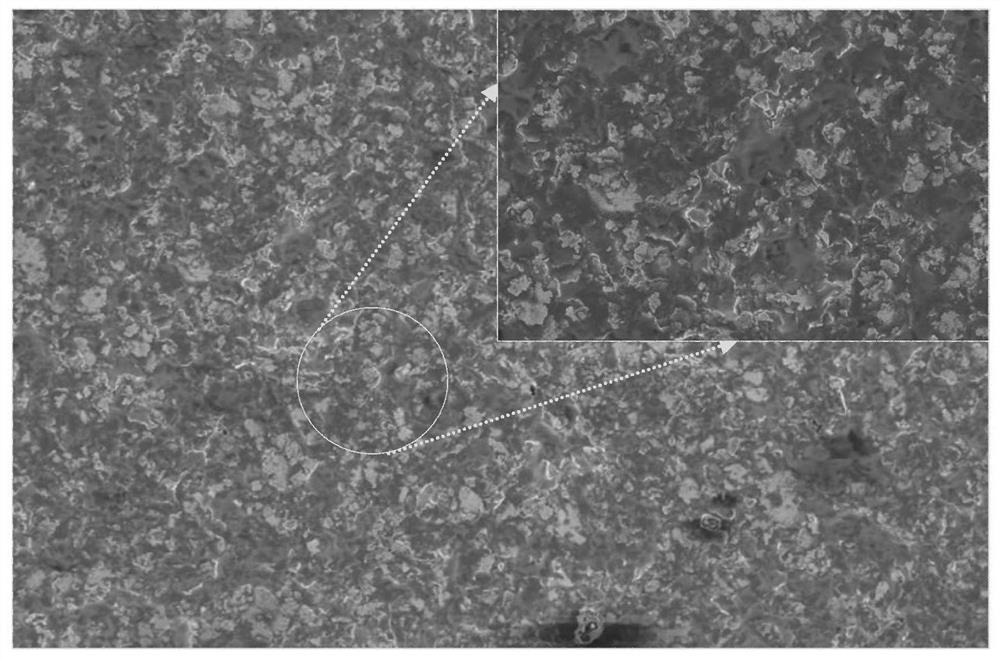

[0034] The conductive filler is composed of nanoscale spherical silver powder, micron-shaped silver powder, and micrometer bar-shaped silver powder, wherein the sheet silver powder and the rod silver powder are arranged according to the ratio of (0-10: 10 ~ 0). The content of sheet silver powder and rod silver powder accounts for 20 to 75% of total quality;

[0035] The mass ratio of the compound silver powder and the spherical silver powder is (1 to 10): 1;

[0036] Among them, the particle diameter of the sheet silver powder is 2 to 4 μm, and the particle silver powder has a particle diameter of from 0.001 to 0.1 μm, the tube diameter of the silver powder is 0.02 to 0.1 μm, and the length is 1 to 5 μm.

[0037] Further...

Embodiment 2

[0041] Preparation method of conductive silver paste, including the following specific steps:

[0042] (1) Add the nanoscopic silver powder, micron-shaped sheet silver powder to the alcohol solution dispersant, treated with ball milling, and dispersion of the bar-shaped silver powder and the sheet silver powder;

[0043] (2) Add a spherical silver powder to the alcohol solution dispersant, performing an ultrasonic emulsion, forming a uniform rod silver powder dispersion emulsion, then add step (1) to disperse a uniform silver powder solution, stir, while stirring, 3 to 5 After the addition is added, the ball mill is divergently after adding silver powder;

[0044] (3) After the linear oligomer is added to the dispersant, the mixture is mixed with high speed for 30 to 80 min, and then the ground is reduced to 5 μm or less;

[0045] (4) After using a vacuum mixer to filter the remaining auxiliaries, epoxy resin, after filter defoaming treatment, the curing agent is mixed, and the cu...

Embodiment 3

[0050]According to the proportion of photo-like silver powder and rod silver powder, 6 groups of experiments according to (0 ~ 10: 10 ~ 0), the first group of experiments: sheet silver powder: rod silver powder = 10: 0, second group experiment: flake silver powder: rod Silver powder = 8: 2, third group of experiments: sheet silver powder: stick-shaped silver powder = 6: 4, fourth group of experiments: sheet silver powder: stick-shaped silver powder = 4: 6, fifth group of experiments: sheet silver powder: rod silver powder = 2: 8, sixth group of experiments: sheet silver powder: rod silver powder = 0: 10; 6 groups of conductive silver paste were obtained in accordance with the preparation method in Example 2, and 6 groups of conductive silver paste were electrically tested. The result is as shown in Table 1:

[0051] Table 1 Conductive silver paste resistivity test results

[0052] Conductive silver paste Resistivity (Ω.cm) 1 1.7*10 -3

[0053] As the conductive fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com