Oxygen evolution reaction electrocatalyst and preparation method thereof

A technology of oxygen evolution reaction and electrocatalyst, which is applied in the field of electrocatalysis, can solve the problems of multi-step, waste of time and energy, and achieve the effects of saving time, good stability, stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

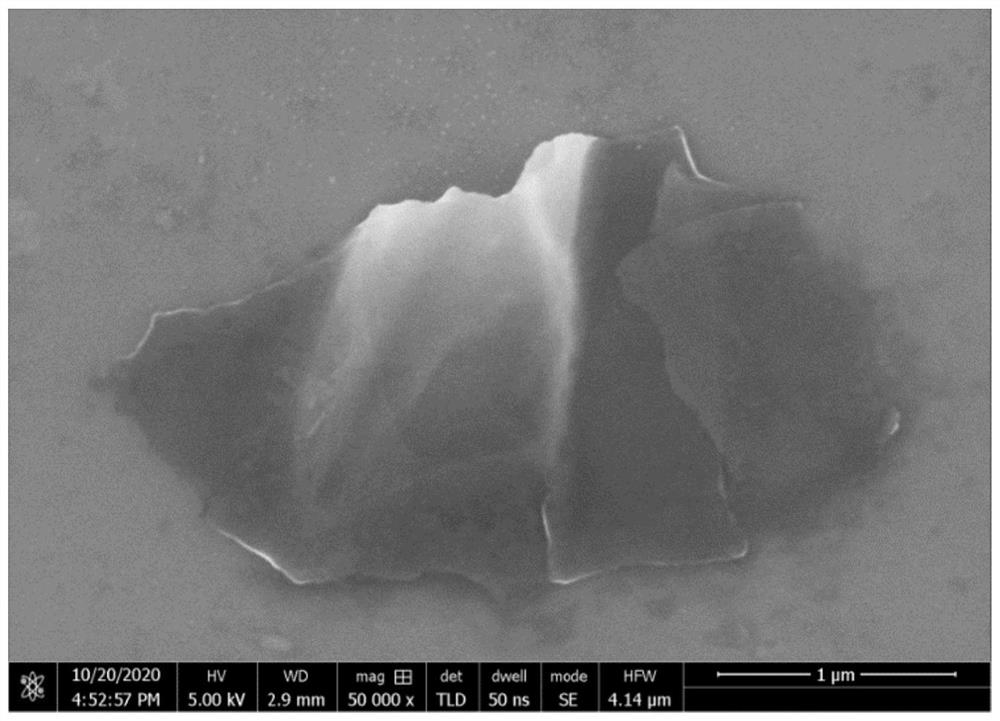

[0033] A preparation method of an oxygen evolution reaction electrocatalyst according to an embodiment of the present invention uses electrochemical exfoliation to prepare a composite material BP (metal A x Metal B y ); wherein, the composite material is formed by applying a voltage to reduce the metal element in the metal salt into the black phosphorus (BP) nanosheet in situ. Among them, black phosphorus (BP) nanosheets such as figure 1 shown.

[0034] Exemplarily, the anode is clamped with platinum wire, the cathode clamp is clamped with an electrode clamp of 10-80 mg black phosphorus block, and the cathode and the cathode are inserted into the electrolytic cell. mol*x metal salt A, 0.015mol*y metal salt B and 10 ~ 80ml N, N-dimethylformamide solution, and then apply a constant and suitable voltage (optional, measure the applied voltage with a constant voltage meter, the voltage range 5~30V), perform electrochemical stripping and metal salt reduction, centrifuge after str...

Embodiment 2

[0038] A preparation method of an oxygen evolution reaction electrocatalyst according to an embodiment of the present invention, the oxygen evolution reaction electrocatalyst is BP(Ni 3 Mo 1 ), the specific steps include: the anode is clamped with platinum wire, the cathode clamp is clamped with an electrode clamp of 10-80 mg black phosphorus block, the cathode and the cathode are inserted into the electrolytic cell, and there is 0.1 to 0.8 g of tetrabutyl ammonium tetrafluoroborate in the electrolytic cell , 0.015mol*3 anhydrous nickel chloride, 0.015mol*1 anhydrous molybdenum pentachloride and 10 ~ 80mlN, N-dimethylformamide solution, and then apply a constant and suitable voltage (optional, by constant voltage The applied voltage is measured by the electric meter, the voltage range is 5-30V), and electrochemical stripping and metal salt reduction are carried out. After stripping and reduction, centrifuge, wash, and dry to obtain the composite material BP (Ni 3 Mo 1 ).

...

Embodiment 3

[0041] A preparation method of an oxygen evolution reaction electrocatalyst according to an embodiment of the present invention, the oxygen evolution reaction electrocatalyst is BP(Ni 3 Fe 1 ), the specific steps include: the anode is clamped with platinum wire, the cathode clamp is clamped with an electrode clamp of 10-80 mg black phosphorus block, the cathode and the cathode are inserted into the electrolytic cell, and there is 0.1-0.8 g tetrabutylammonium tetrafluoroborate in the electrolytic cell , 0.015mol*3 anhydrous nickel chloride, 0.015mol*1 anhydrous ferric chloride and 10-80ml N, N-dimethylformamide solution, and then apply a constant and suitable voltage (optional, by constant The piezoelectric meter measures the applied voltage, the voltage range is 5 ~ 30V), and electrochemical stripping and metal salt reduction are carried out. After stripping and reduction, centrifuge, wash, and dry to obtain the composite material BP (Ni 3 Fe 1 ).

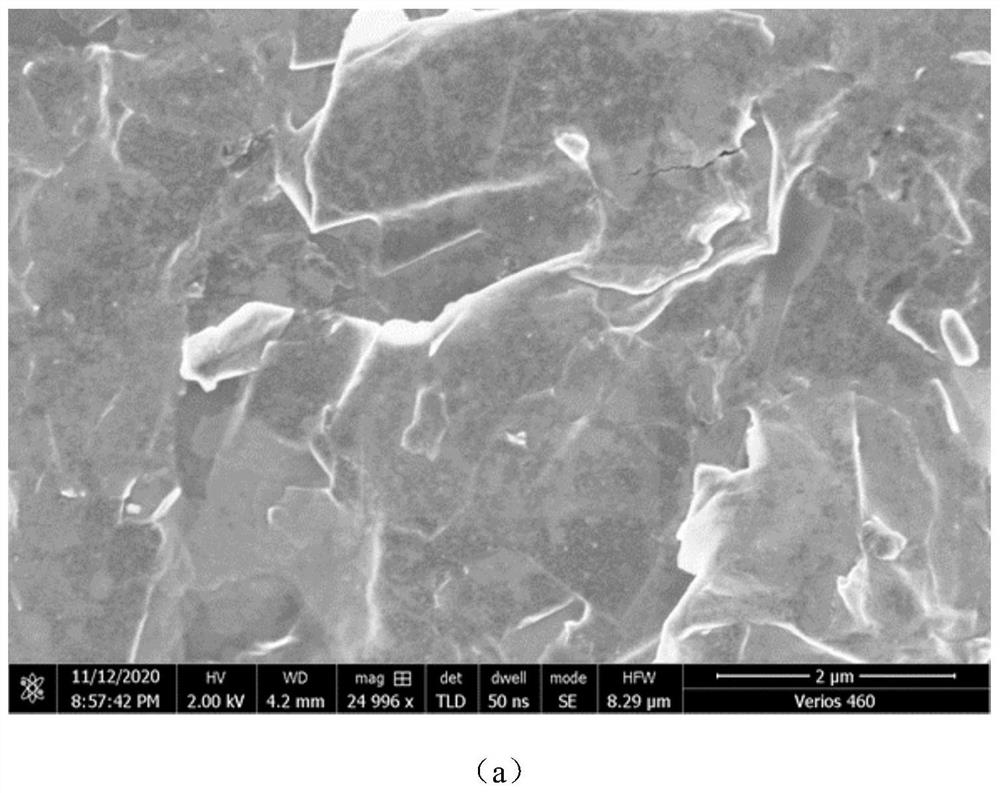

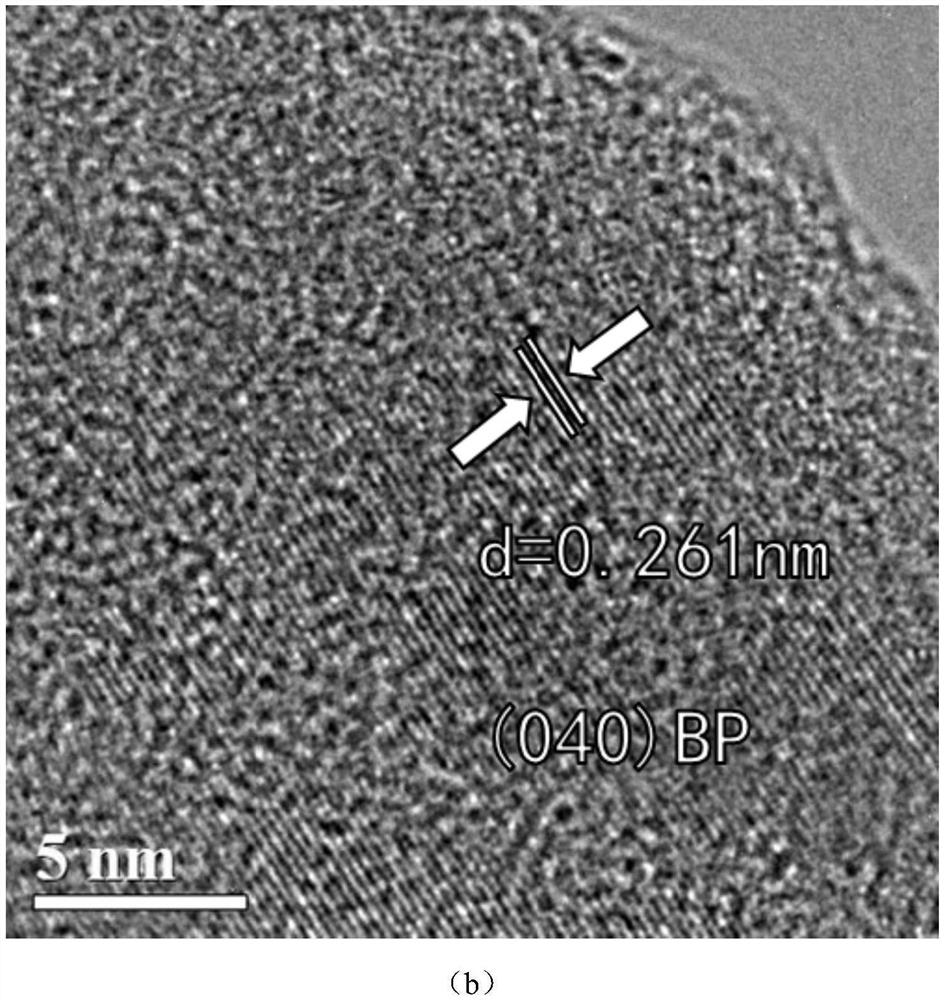

[0042] see Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com