Converter equipment mounting method

A technology of equipment installation and converter, which is applied in the manufacture of converters, etc., can solve the problems of cumbersome installation, poor stability, and difficult precision control, etc., and achieve the effects of simplifying the construction process, easy operation, and improving overall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

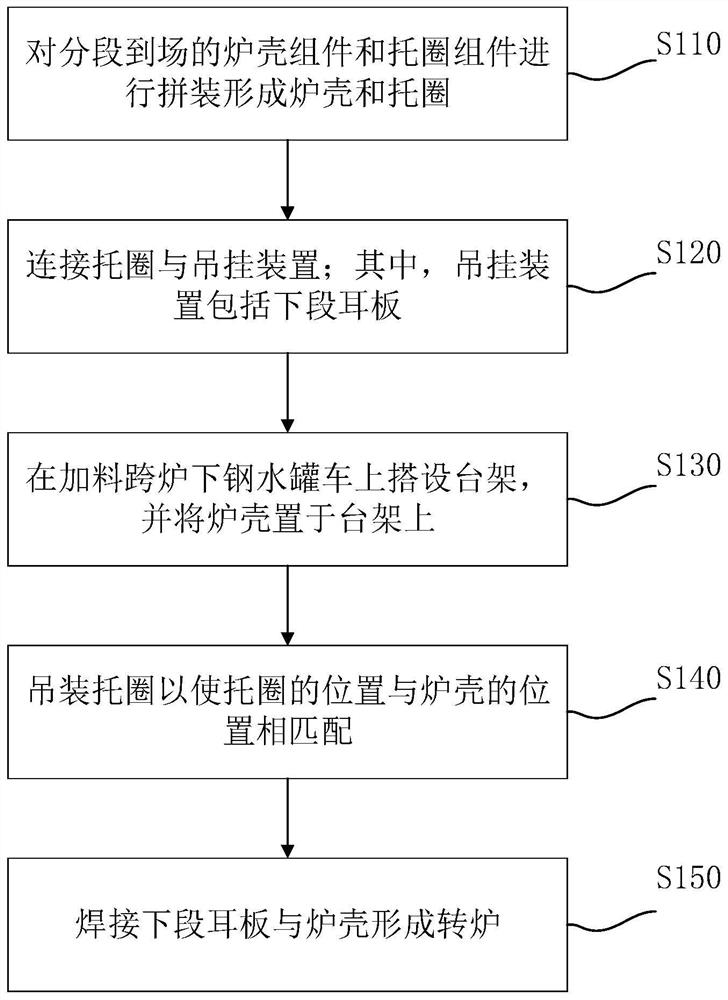

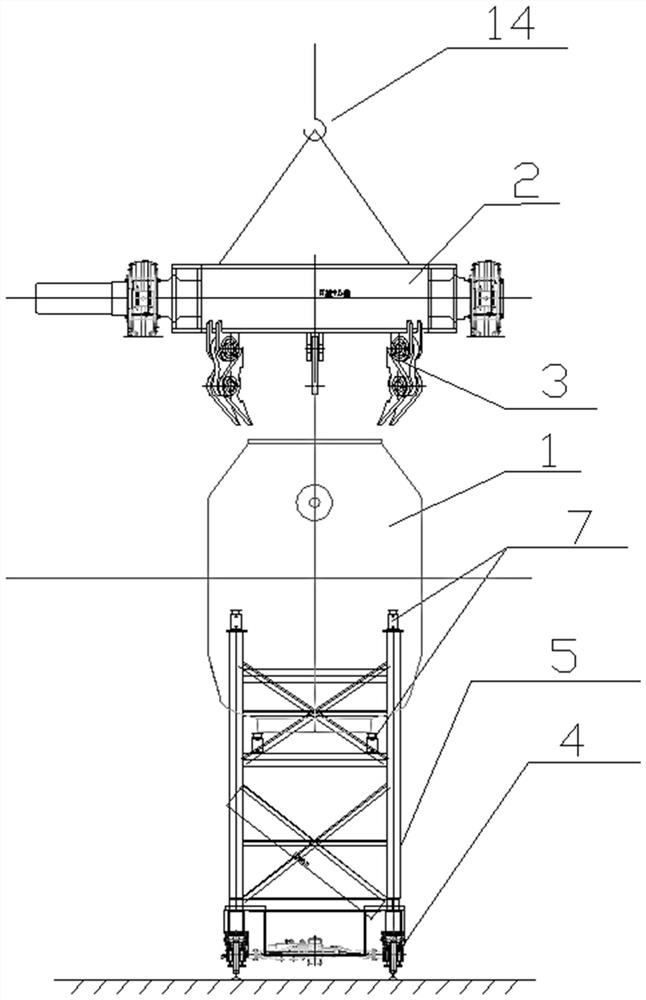

[0043] The traditional converter installation adopts the method of sliding jacking, that is, firstly the stripping ring and the furnace shell are assembled into a whole on the ground, and then the supporting ring and the furnace shell are successively hoisted on the sliding jacking platform above the ladle car. After alignment, the installation is carried out at high altitude, the installation work is cumbersome, the stability is poor, and the precision control is difficult.

[0044] In view of the above problems, the present invention provides a method for installing converter equipment, and specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0045] The following description of the exemplary embodiments is merely illustrative in nature and in no way is taken as any limitation of the invention and its application or use. Techniques and equipment known to those of ordinary skill in the relevant art may n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com