A kind of copolyester and preparation method thereof

A technology of polyester and citramalate-based polyester, applied in the field of polyester and its preparation, can solve the problems of reduced tensile strength, inability to take into account strength and toughness at the same time, long synthesis process, etc., and achieves excellent toughness and rapid degradation rate improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

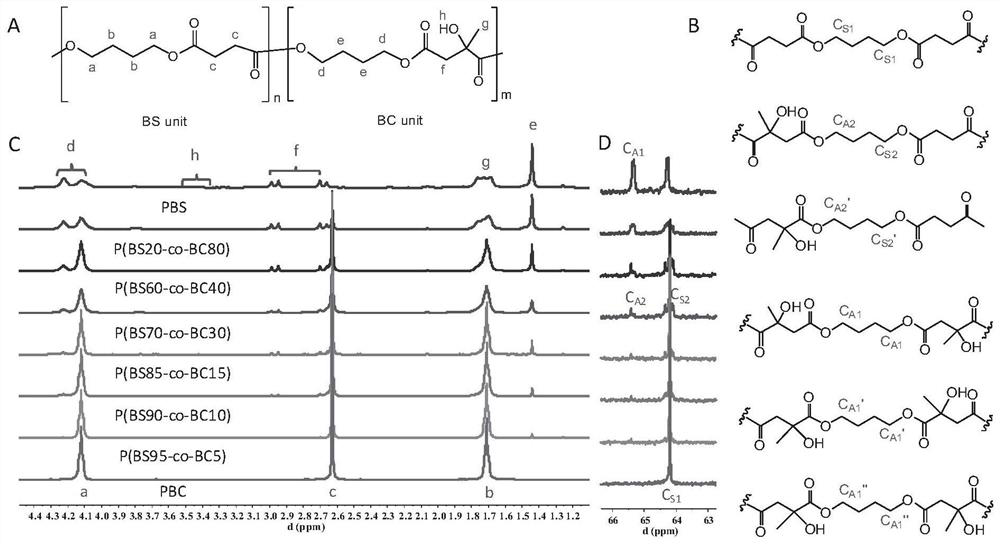

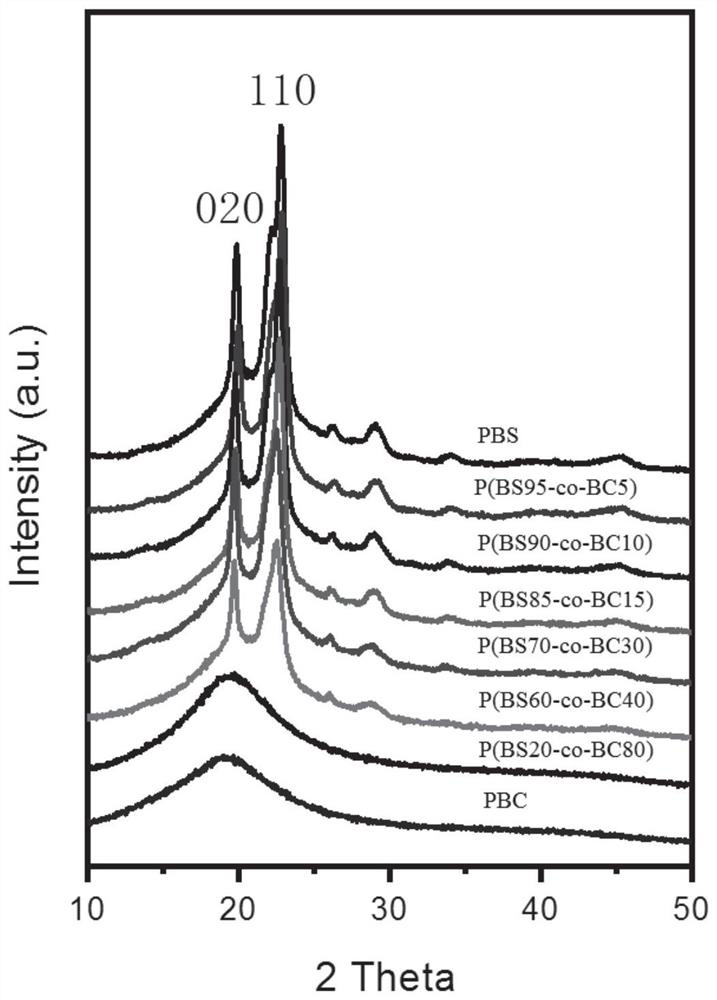

Method used

Image

Examples

Embodiment 1

[0045] Weigh 0.74g citramalic acid, 11.21g succinic acid, 22.53g 1,4-butanediol, 0.17g tetrabutyl titanate, add these materials into a 100ml three-necked flask, and fill the reaction system with nitrogen Protective gas, start stirring (speed: 80r / min), turn on the oil bath and heat to 160°C for 1h esterification, 180°C for 5h, stop filling nitrogen, turn on the vacuum pump to evacuate the reaction system to 100Pa, heat up to 200°C, When the reaction system reaches 200°C, start timing and polycondensate for 3.5 hours. After the reaction, stop the vacuum pump, take out the polyester, and record it as polymer P(BS95-co-BC5). The samples were characterized by tests such as molecular weight, glass transition temperature Tg, water resistance, and elongation at break.

Embodiment 2

[0047] Weigh different citric malic acid and succinic acid as follows:

[0048] 1) Weigh 1.48g citric acid, 10.62g succinic acid;

[0049] 2) Weigh 2.22g citric malic acid, 10.03g succinic acid;

[0050] 3) Weigh 4.44g citric malic acid, 8.26g succinic acid;

[0051] 4) Weigh 5.92g citric acid, 7.08g succinic acid;

[0052] 5) Weigh 11.84g citric malic acid, 2.36g succinic acid;

[0053] The amount of 1,4-butanediol and the synthetic method of polyester are the same as in Example 1, and the prepared polymers are respectively denoted as polymers P(BS90-co-BC10), P(BS85-co-BC15), P(BS70- co-BC30), P(BS60-co-BC40), P(BS20-co-BC80).

Embodiment 3

[0055] Weigh 15.52 g of ethylene glycol, the dosage of citramalic acid and succinic acid and the synthetic method of polyester are the same as in Example 1, and it is recorded as polymer P (ES95-co-EC5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com