A kind of tea seed shell kernel separator

A technology of shell kernel separation and tea seed separation, applied in magnetic separation, solid separation, separation of solids from solids by air flow, etc., can solve the problems of metal leakage, poor separation effect of shell kernels, and difficulty of metal adsorption by magnets, etc. , to achieve the effect of improving adsorption performance, complete separation of shell and kernel, and excellent shelling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

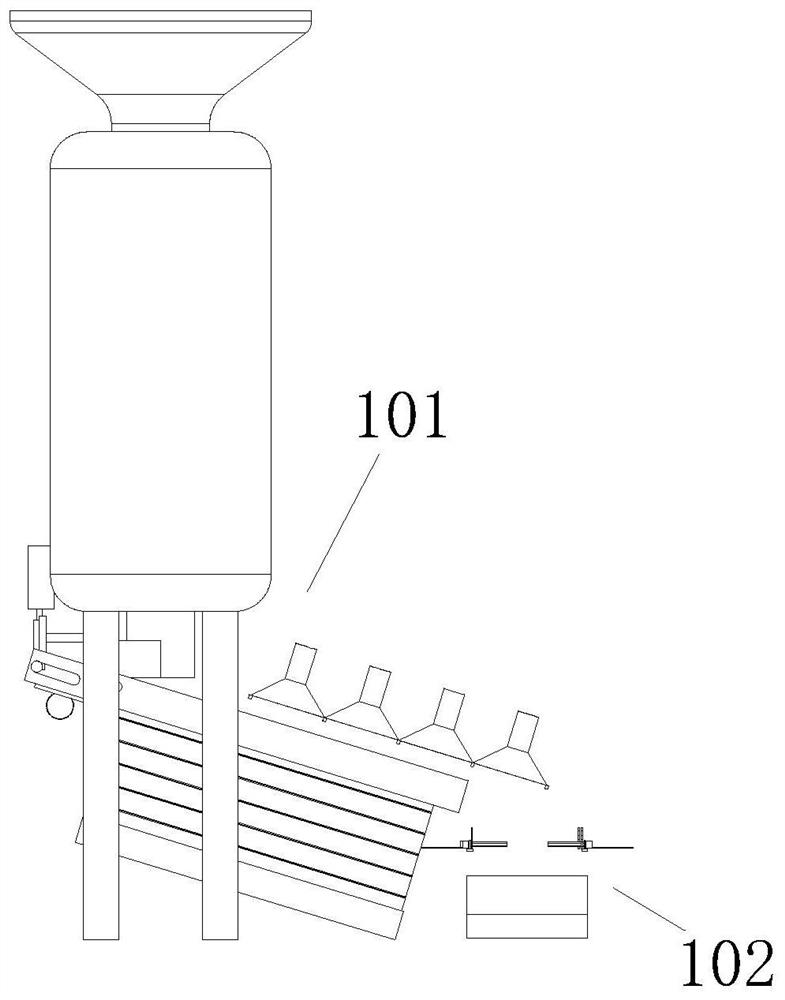

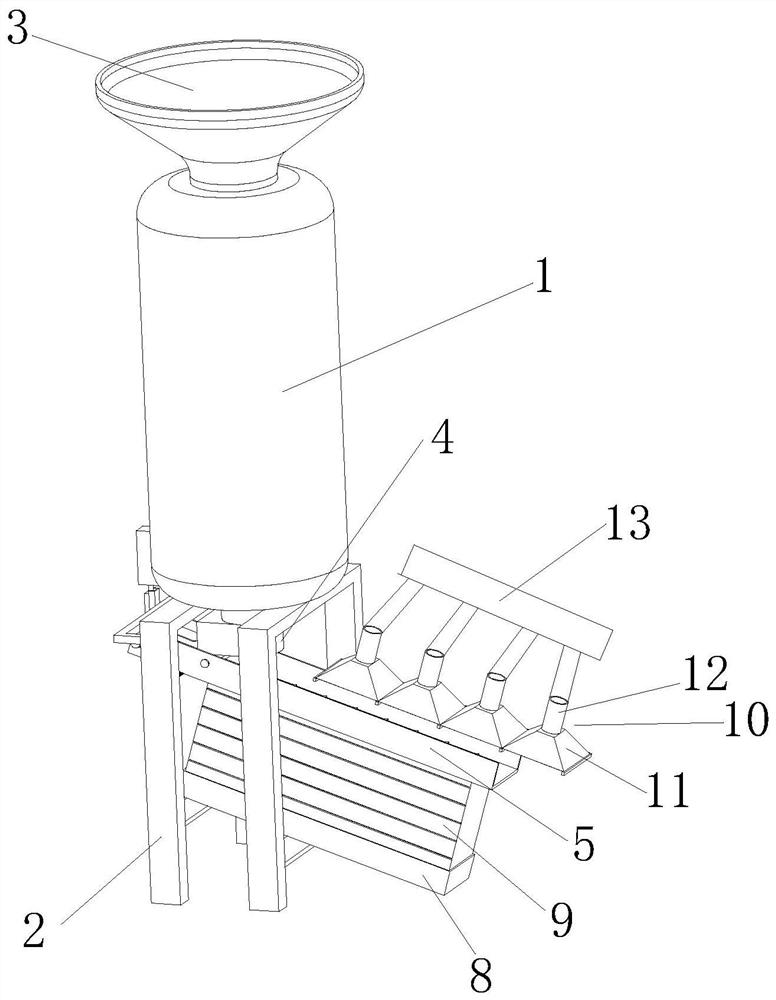

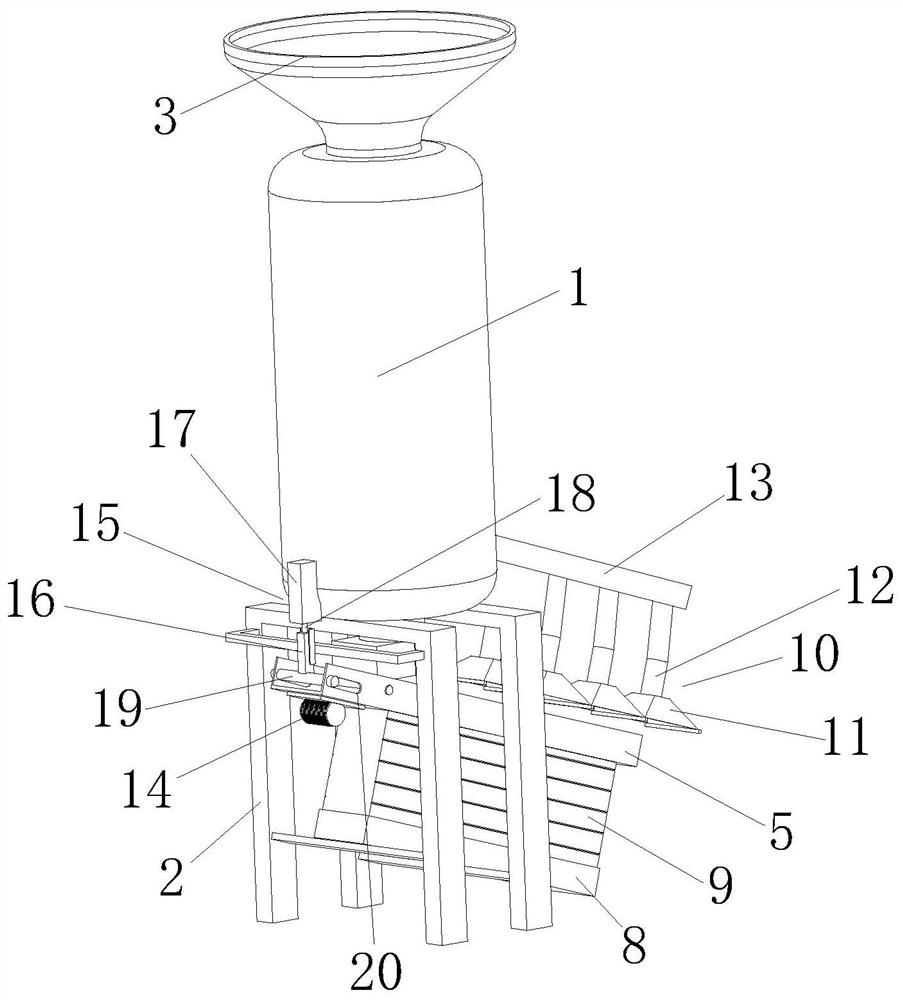

[0031] like Figure 1-Figure 9 As shown, a tea seed husk kernel separator includes a husk removal device 101 and a metal removal device 102,

[0032]The dehulling device 101 includes a centrifugal shell breaker 1, a support frame 2 for supporting the centrifugal shell breaker 1, and the upper end of the centrifugal shell breaker 1 is provided with a feeding port 3, and the feeding port 3 is an expansion port. Mouth-shaped structure, the lower end of the centrifugal shell breaker 1 is provided with a discharge pipe 4, the lower end of the discharge pipe 4 is rotatably connected with a chute 5 that is always inclined downward, and the inner bottom of the chute 5 is fixedly provided with a convex Block 6, the protrusion 6 is provided with an air outlet 7 which is connected with the lower end face of the chute 5; the protrusions 6 in the chute 5 are arranged in multiple rows and distributed along the length direction of the chute 5, adjacent to each other. The bumps 6 in the row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com