Preparation method and application of FeSb/NC electrocatalyst

An electrocatalyst, fe2.55sb2 technology, applied in physical/chemical process catalysts, chemical instruments and methods, circuits, etc., can solve the problem of poor ORR performance, and achieve good stability and excellent ORR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take a beaker first, add ethanol in order at room temperature (C 2 Hide 5 OH) 10 ml, nine water in iron (FE (NO 3 ) 3 ∙ 9h 2 O) 200 mg, trichloride (SBCL 3 100 mg, dicyandiamide (C 2 Hide 4 N 4 2 g and Philippine (C 12 Hide 8 N 2 0.2 g, stir after 30 min, ultrasonic 5 min. Subsequently, the beaker was stirred at 80 ° C to dry, and the obtained powder was well grinded in the mortar, and then placed in the center of the tube furnace, heating 5 ° C / min at a high purity AR atmosphere to 900 ° C, high temperature heat Solution 2 h Get a new FeSB / NC electrocatalyst, labeled FESB / NC-1.

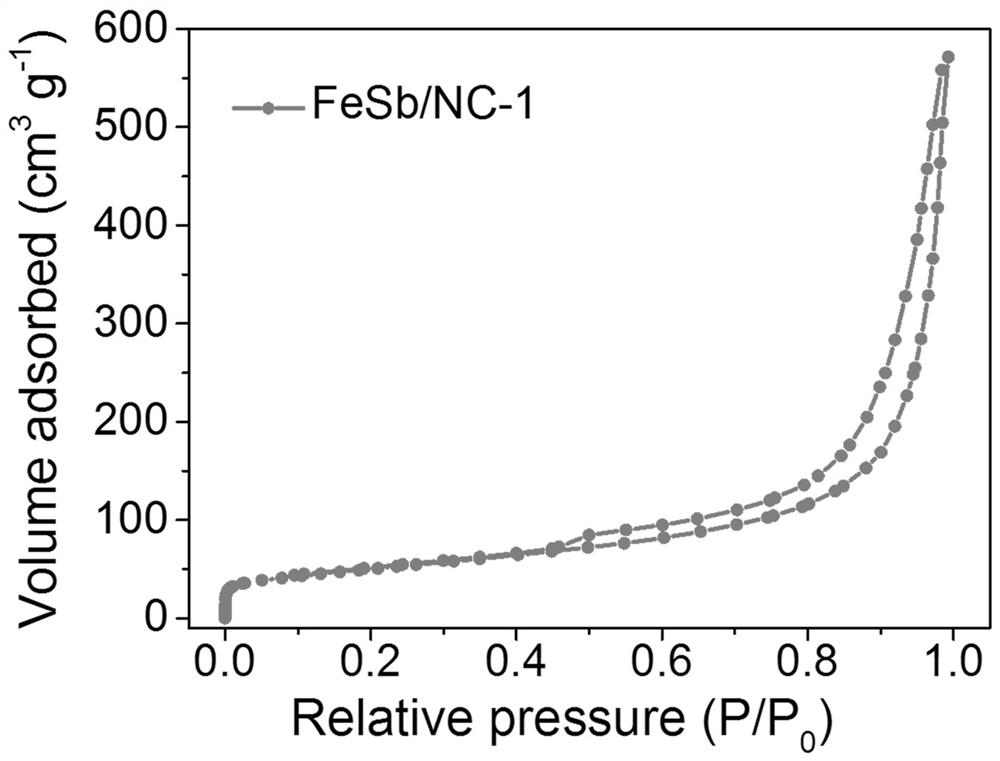

[0022] figure 1 In this example, the FESB / NC-1 is an XRD spectrum of the catalyst, in the figure, located in 26 o The wider derived peak of the left and right is the (002) peak of graphitized carbon, from the high temperature carbonization of the precursor of the dicyandide. Cali-diffraction peak and Fe of other angles 2.55 SB 2 The standard card (PDF # 54-0502) corresponds to one or one,...

Embodiment 2

[0024] Take a beaker first, add ethanol in order at room temperature (C 2 Hide 5 OH) 10 ml, nine water in iron (FE (NO 3 ) 3 ∙ 9h 2 O) 200 mg, trichloride (SBCL 3 100 mg, dicyandiamide (C 2 Hide 4 N 4 2 g and Philippine (C 12 Hide 8 N 2 0.3 g, after stirring for 30 min, ultrasound 5 min. Subsequently, ethanol in the beaker was stirred at 80 ° C to dry, and the obtained powder was well grounded in the mortar, and placed in the center of the tube furnace, 5 ° C / min at a high pure Ar atmosphere to 900 ° C, high temperature heat The solution 2 h gave a new FeSB / NC electrocatalyst, labeled FESB / NC-2.

[0025] figure 1 In this example, the FESB / NC-2 is the XRD spectrum of the catalyst. As in Example 1, located in 26 o The wider derived peak is the (002) peak of the graphitized carbon produced by the high temperature carbonization of the dicyandide precursor. Cali-diffraction peak and Fe of other angles 2.55 SB 2 The standard card (PDF # 54-0502) corresponds to one or one, prove...

Embodiment 3

[0027] Take a beaker first, add ethanol in order at room temperature (C 2 Hide 5 OH) 10 ml, nine water in iron (FE (NO 3 ) 3 ∙ 9h 2 O) 100 mg, trichloride (SBCL 3 100 mg, dicyandiamide (C 2 Hide 4 N 4 2 g and Philippine (C 12 Hide 8 N 2 0.2 g, stir after 30 min, ultrasonic 5 min. Subsequently, ethanol in the beaker was stirred at 80 ° C to dry, and the obtained powder was well grounded in the mortar, and placed in the center of the tube furnace, 5 ° C / min at a high pure Ar atmosphere to 900 ° C, high temperature heat Solution 2 h Get a new FeSB / NC electrocatalyst, labeled FESB / NC-3.

[0028] figure 1 In this example, the FESB / NC-3 is the XRD spectrum of the catalyst, which is the same as in Examples 1, 2, located in 26. o The wider derived peak of the left and right corresponds to the (002) peak of the graphitated carbon, from the high temperature carbonization of the prodium of the dicyanide, the sharp diffraction peak and Fe of other angles 2.55 SB 2 The standard card (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com