Self-adjusting intelligent chemical stirring machine

A self-adjusting, mixer technology, applied in mixer accessories, mixers with rotary stirring devices, mixers, etc., can solve the problems that raw materials cannot be replenished in time, affect chemical mixing efficiency, reduce reaction processing effects, etc., and achieve the reaction stirring effect. Good, high degree of automation, easy to assemble and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

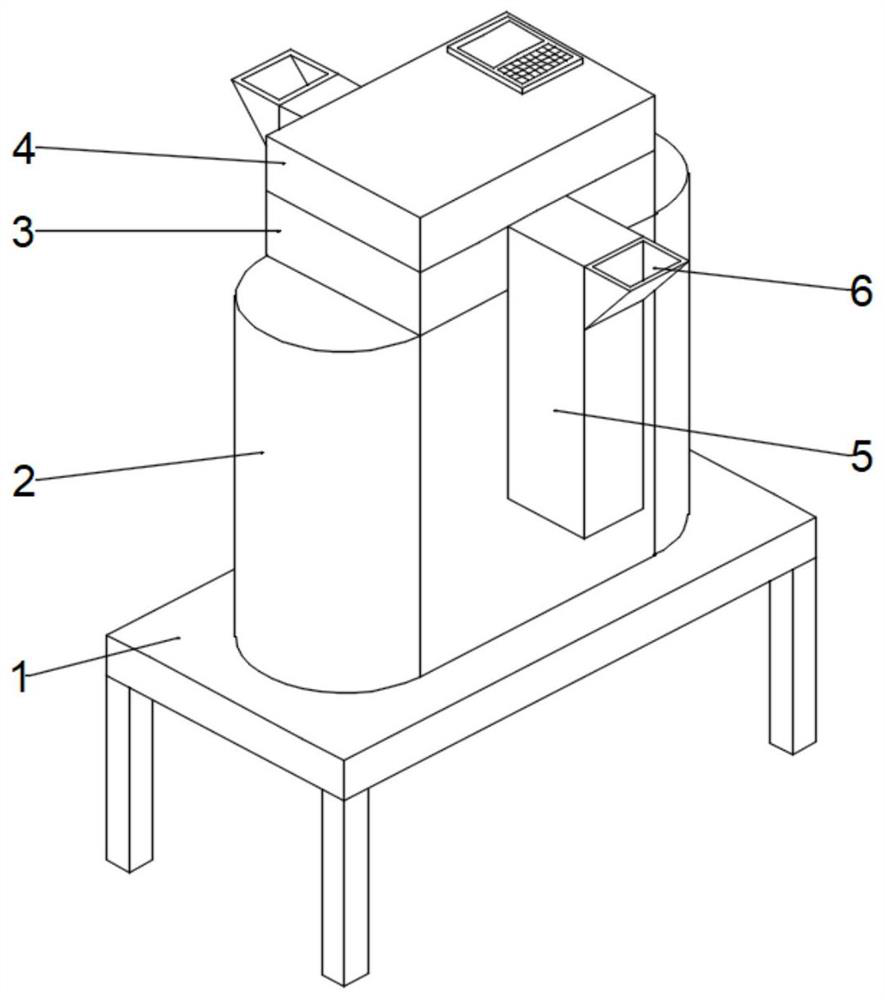

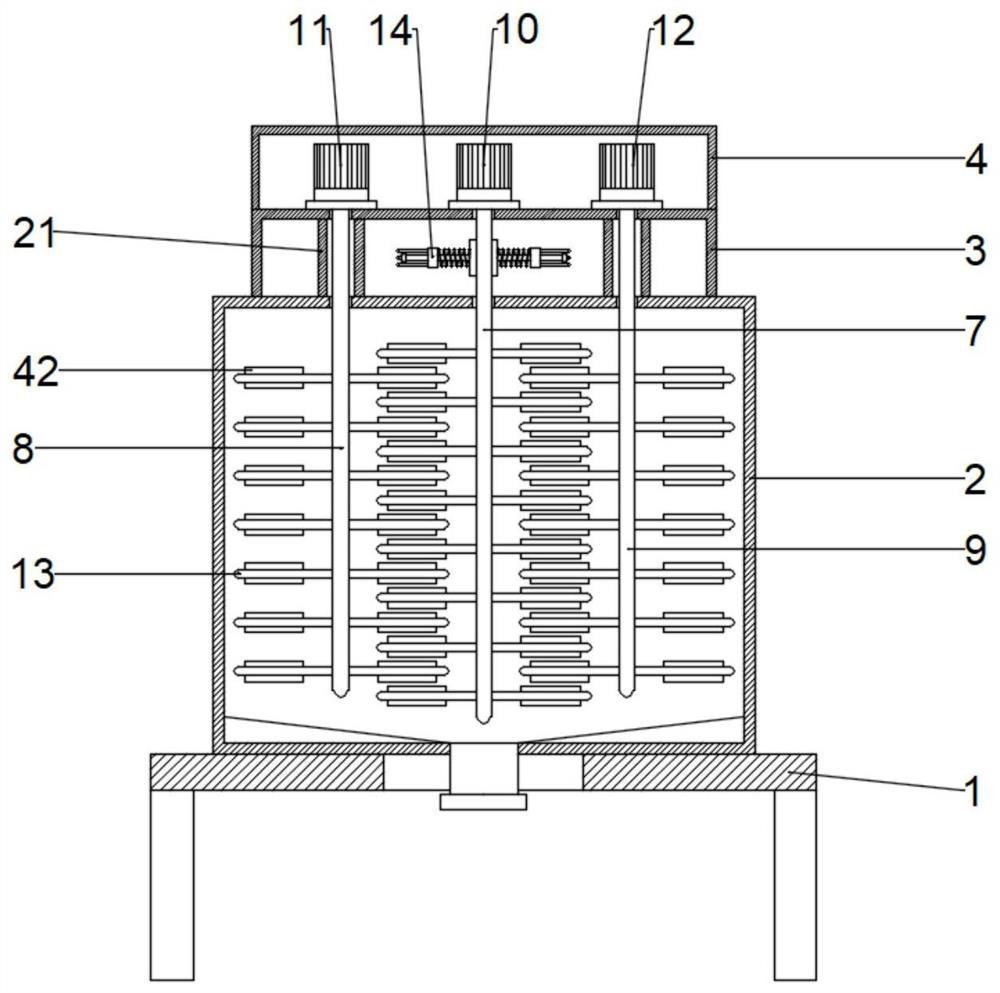

[0033] see figure 1 , 2 , a self-regulating intelligent chemical mixer, comprising a mixing box 2, a feeding box 5 and an adjustment system, the mixing box 2 is installed on the base 1, the bottom of the mixing box 2 is provided with a discharge pipe, and the side wall of the mixing box 2 is provided There is a liquid injection pipe for injecting the reaction solution and a discharge pipe (not shown in the figure) for exporting the gas generated by the reaction. The stirring box 2 is provided with a stirring shaft group, and one end of the stirring box 2 is connected to a working box. 3. The top of the working box 3 is installed with a driver group, one end of the stirring shaft group passes through the working box 3 and is connected with the driving unit correspondingly, and the inside of the working box 3 and the stirring shaft group are connected with an adjusting drive Assemblies 14, the two sides of the working box 3 are provided with adjustment adapter assemblies 27, th...

Embodiment 2

[0037] refer to Figure 2-4 , on the basis of Embodiment 1, the adjustment drive assembly 14 includes a fixed sleeve 15 connected to the first stirring shaft 7, a number of connecting rods 16 connected to the outer wall of the fixed sleeve 15, and sleeved on the connecting rod 16 The sliding sleeve 18 on the top, the connecting rod 16 is circumferentially symmetrically distributed and connected to the fixed sleeve 15, and one end of the sliding sleeve 18 is connected with the outer wall of the fixed sleeve 15 through an elastic member, and the elastic member can be selected as a spring 17, an elastic wire The other end of the sliding sleeve 18 is connected with a plurality of first pressing rods 19, and the first pressing rods 19 are circumferentially symmetrically arranged on the periphery of the connecting rod 16. The connecting rods 16 is provided with a first limit sleeve 20 at one end away from the fixed sleeve 15 to prevent the sliding sleeve 18 from accidentally falling...

Embodiment 3

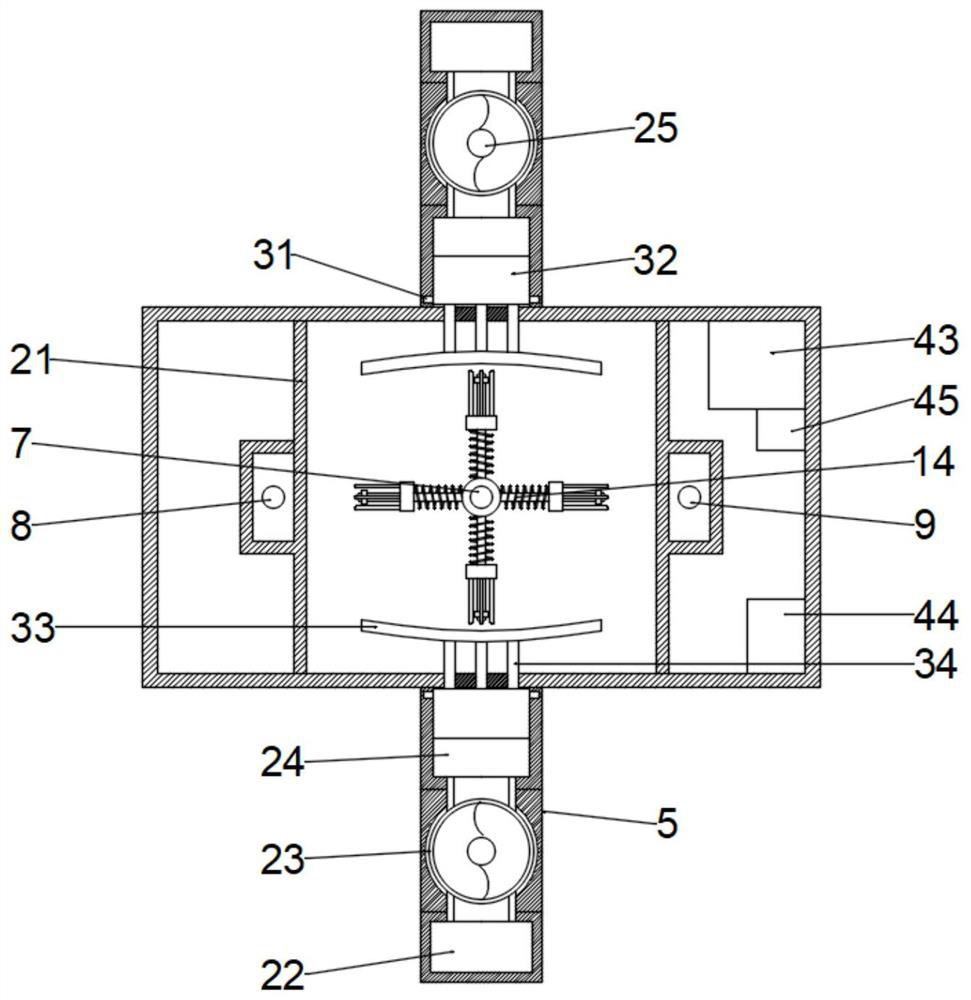

[0041] refer to Figure 5 , 6 , on the basis of Embodiments 1 and 2, a liquid level detector 40 is provided in the volume control chamber 24, and the detection end of the liquid level detector 40 extends to the inner cavity of the stirring tank 2, and the liquid level detector 40 to detect the change of the liquid level in the mixing tank 2, on the one hand, the dosage of the reaction solution in the mixing tank 2 can be adjusted in time, and on the other hand, it can timely give an early warning to prevent the reaction solution from penetrating into the volume control chamber 24 through the discharge port 36 middle.

[0042] Working principle: when in use, put the reaction raw material into the accumulation chamber 22 through the feed tank 6, inject a suitable reaction solution into the inner cavity of the stirring box 2 through the liquid injection pipe, and then start the fourth driving member 26 to drive the feed rod 25 to rotate and The reaction raw materials are transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com