Screw for extruder, and extruder

A technology of extruder and screw, which is applied in applications, household components, household appliances, etc. It can solve the problems of material breaking, extrusion molding, and no material discharge, and achieve a good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle and structure of the present invention will be described in detail below in conjunction with the drawings and embodiments.

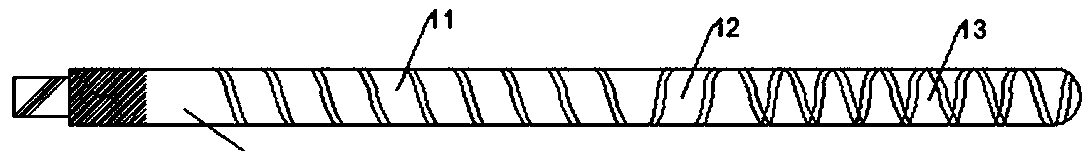

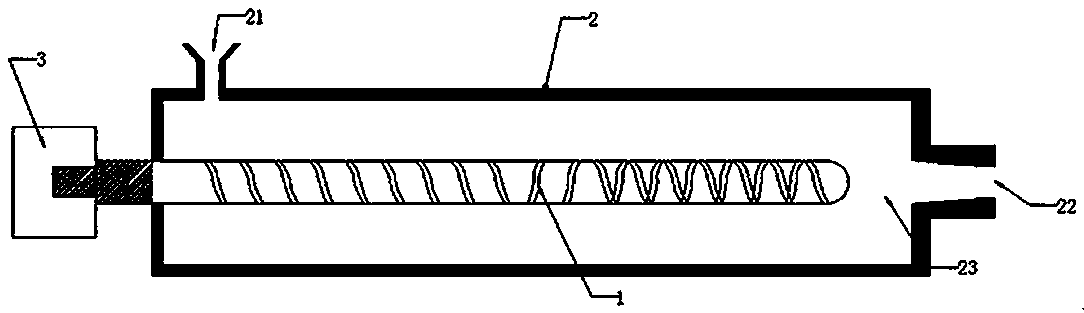

[0015] Such as figure 1 As shown, the present invention proposes a screw used for extruders. The threads on the surface of the screw 1 divide the screw into a stirring section 11 , a spacer section 12 and a backpressure section 13 arranged in sequence according to the direction of rotation of the screw grooves. The section near the end of the screw is a stirring section 11 with a positive single thread groove on the surface, wherein the screw compression ratio of the stirring section 11 is between 1:1.5 and 1:1.7; followed by the spacer section 12, the spacer section The thread groove is a reverse single thread groove, which makes the material being stirred and pressed slow down when it is conveyed. Finally, the reverse pressure section 13 of the opposite direction double thread groove with reverse thread groove and forward thread gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com