Liquid nitrogen cooling device of synthetic resin preparation reaction kettle

A technology of liquid nitrogen cooling and resin synthesis, applied in chemical/physical/physical-chemical stationary reactors, dispersed particle separation, chemical/physical/physical-chemical processes, etc. Expectation, unsatisfactory stirring effect of stirring device, etc., to achieve complete reaction, improved cooling effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

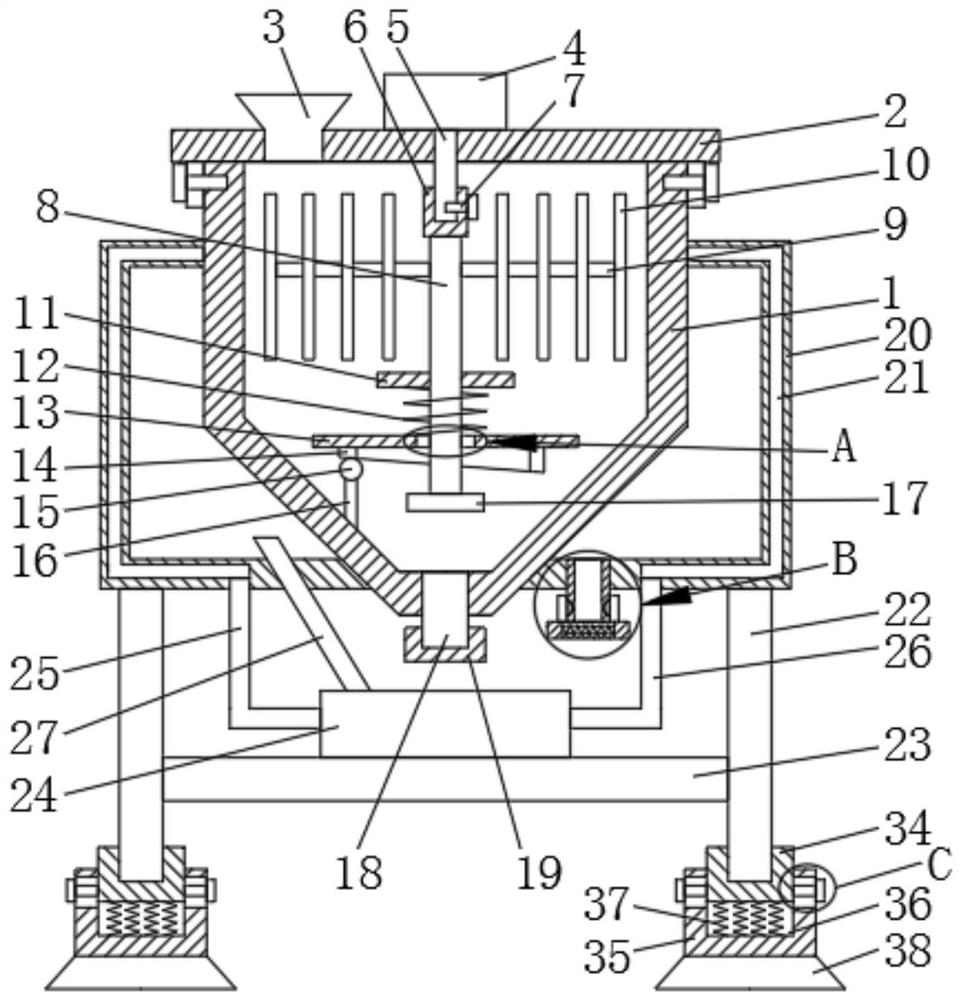

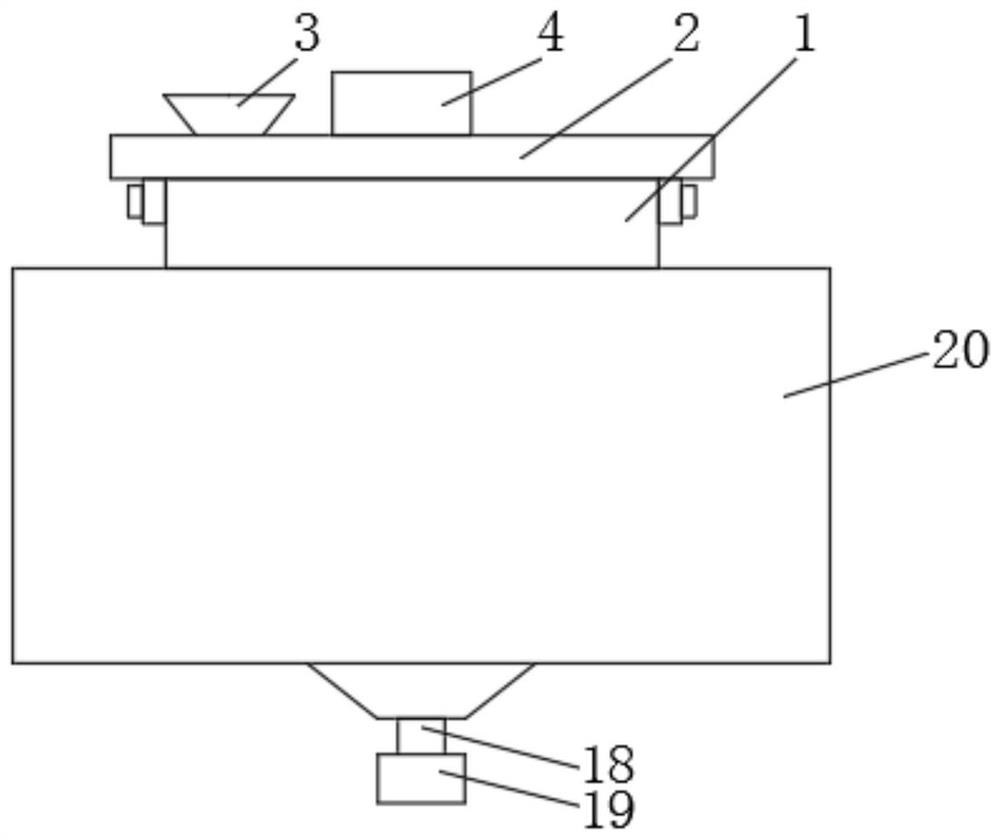

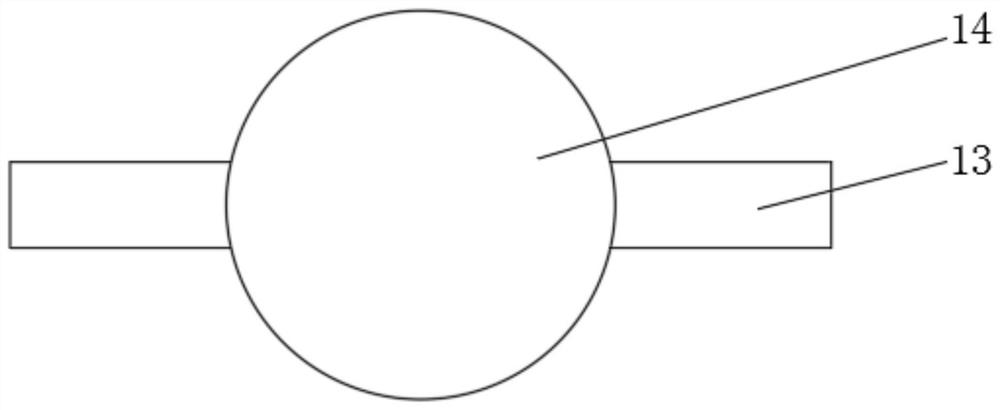

[0026] A liquid nitrogen cooling device for a synthetic resin preparation reactor, comprising a reactor 1 and a cooling box 20, the upper end of the reactor 1 is provided with a cover plate 2 through screws, and the upper end of the cover plate 2 is provided with a material inlet 3 , the upper end of the cover plate 2 is provided with a motor 4, the outer side of the rotating shaft 5 of the motor 4 is sleeved with a connecting sleeve 6, the lower end of the connecting sleeve 6 is fixedly connected with a square rod 8, and the outer side of the square rod 8 A crossbar 9 is fixedly connected, and the outer side of the crossbar 9 is fixedly connected with a first stirring rod 10, and the outer side of the reaction kettle 1 is fixedly connected with a cooling box 20, and the inside of the cooling box 20 is provided with a flow channel 21 A support rod 22 is fixedly connected to the lower end of the cooling box 20 , and a support plate 23 is fixedly connected to the outer side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com