Efficient catalytic oxidation device

A catalytic oxidation, high-efficiency technology, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of insufficient catalytic oxidation reaction, achieve fast speed, good effect, and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

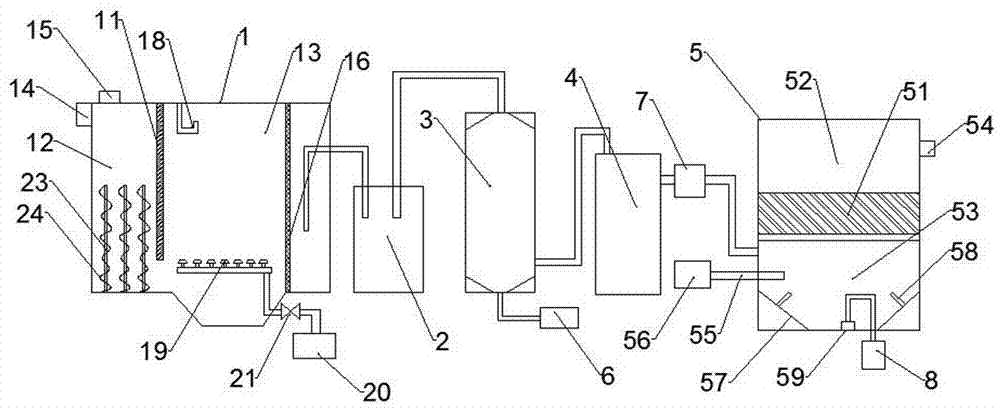

[0019] A high-efficiency catalytic oxidation device, such as figure 1 As shown, it includes coagulation air flotation tank 1, intermediate water tank 2, ozone contact oxidation tower 3, high-efficiency catalytic oxidation tank 4, pipeline mixer 7 and high-efficiency sedimentation tank 5 connected in sequence, and ozone contact oxidation tower 3 is connected with ozone generator 6 , the interior of the coagulation air flotation tank 1 is divided into a mixing zone 12 and an air flotation zone 13 by a vertical partition plate 11, there is a gap between the partition plate 11 and the bottom of the coagulation air flotation tank 1, and the side wall of the mixing zone 12 is set There is a sewage inlet 14, the top of the mixing zone 12 is provided with a dosing port 15, the bottom of the mixing zone 12 is provided with a spiral stirring device driven by a motor, and the air flotation zone 13 is divided into a first zone and a second zone by a mesh filter plate 16. Two areas, the to...

Embodiment 2

[0023] Based on the optimization in Example 1, the bottom of the first area is in the shape of an inverted trapezoid, and the lower end of the filter plate 16 is fixed at the edge of the upper end of the bottom of the inverted trapezoid in the first area.

[0024] The bottom of the first area in this embodiment is in the shape of an inverted trapezoid, which is beneficial to the sludge deposition in the coagulation air flotation tank and facilitates sludge discharge.

Embodiment 3

[0026] Optimization is carried out on the basis of Example 2. The spiral stirring device includes a rotating shaft 23 and a spiral plate 24 arranged along the rotating shaft 23. There are more than two spiral stirring devices, and the rotation directions of adjacent spiral stirring devices are opposite.

[0027] This embodiment limits the structure of the spiral stirring device, the effect of the stirring and stirring by the spiral plate is better, and the reaction speed of the dosing is faster, and more than two spiral stirring devices are set at the same time, and the rotation direction of the adjacent spiral stirring devices is opposite, which can Increase the mixing speed of the liquid medicine and improve the effect of the dosing reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com