Gas management system and method for PEMFC anode recirculation and storage medium

A management system and management method technology, applied in the field of fuel cells, can solve the problems of hydrogen waste, poor economy, hydrogen dilution and stack performance degradation, and achieve the effect of thorough purging and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

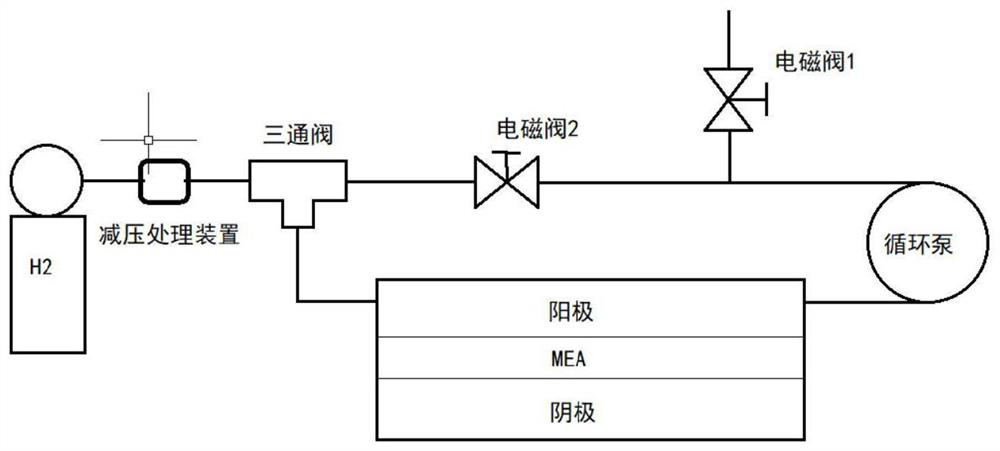

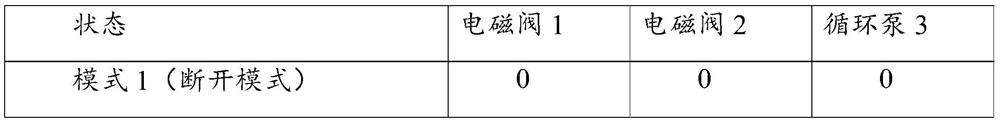

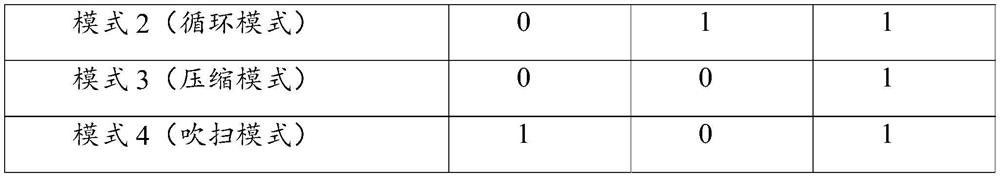

[0041] In the first embodiment, the gas management is realized by controlling the opening and closing of two solenoid valves and the circulation pump. The gas management mode of the anode is divided into four modes, namely the disconnection mode (mode 1) and the circulation mode (mode 2). , compression mode (mode 3), purge mode (mode 4), the control rules of each operation mode can be seen in Table 1:

[0042]

[0043]

[0044] First, the hydrogen management system works in mode 1, where 0 means off and 1 means on. At this time, solenoid valve 1, solenoid valve 2, and circulation pump 3 are not turned on. The high-pressure gas from the hydrogen bottle enters the stack after being decompressed. The continuous accumulation of gas impurities and the uneven distribution of hydrogen concentration on the monomers will increase the pressure difference between the monomers. When a certain threshold is reached, it will enter mode 2, that is, the circulation mode. Impurities in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com