Turbine gas thermal performance uncertainty quantification method and system based on universal Kriging model

A technology of uncertainty and quantification method, which is applied in the field of turbine gas thermal performance uncertainty quantification method and system, which can solve problems such as engineering design disallowance, consumption of computing resources, dimension disaster, etc., to achieve excellent capture ability and improve calculation accuracy , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0039] Example: Uncertainty visual analysis of gas-thermal characteristics for GE_E3 leaf shape. The geometric parameters of GE_E3 leaf shape are shown in Table 1.

[0040] Table 1 Geometric parameters of GE_E3 leaf shape

[0041] geometry parameter name value The coordinates of the starting point of the middle arc (40.00,13.57,-33.74) End point coordinates of the middle arc (124.80,-60.60,-33.74) Leaf height / mm 122.0

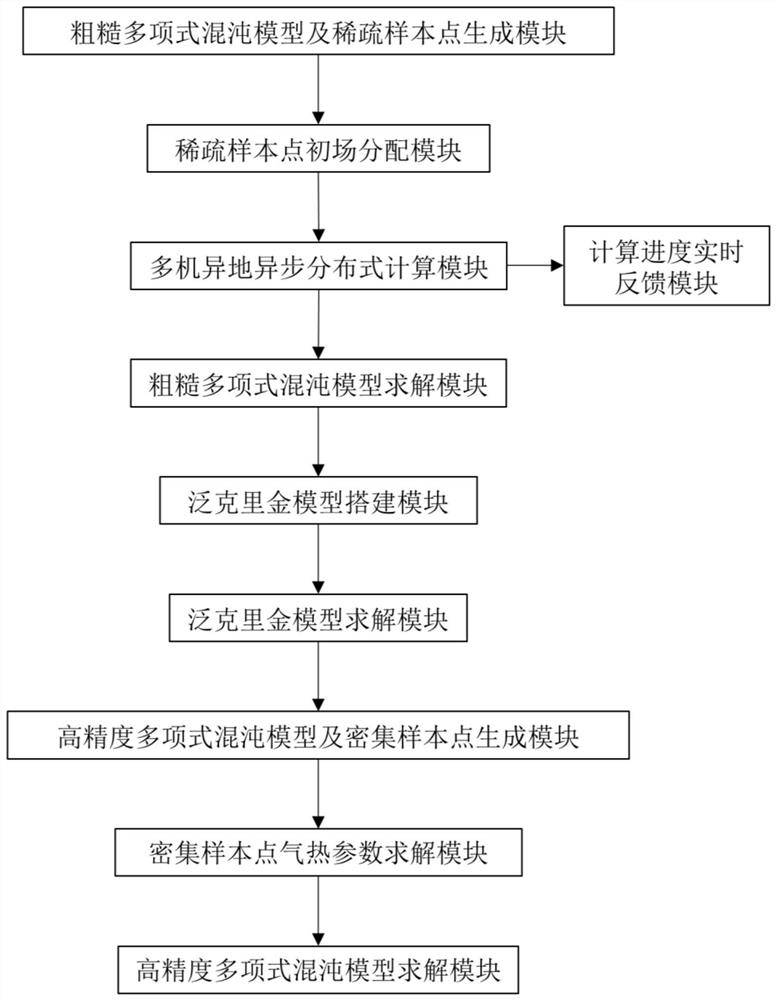

[0042] refer to figure 1 , this embodiment is based on a universal kriging model-based uncertainty quantification system for gas-thermal performance of high-efficiency turbines, including:

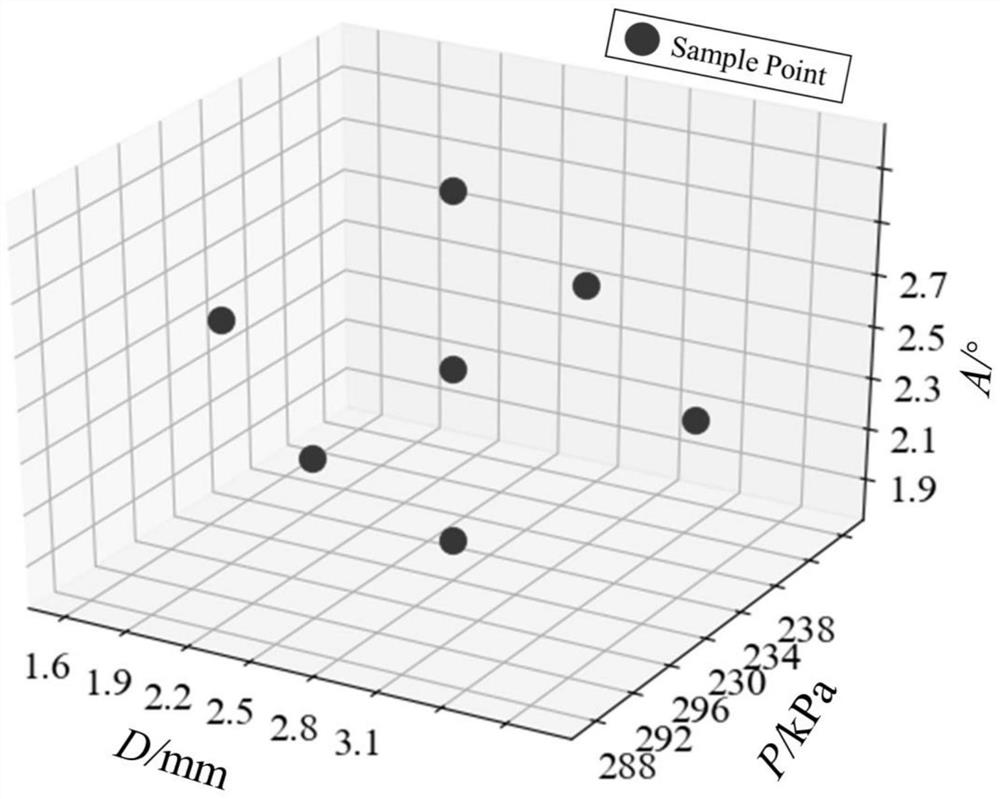

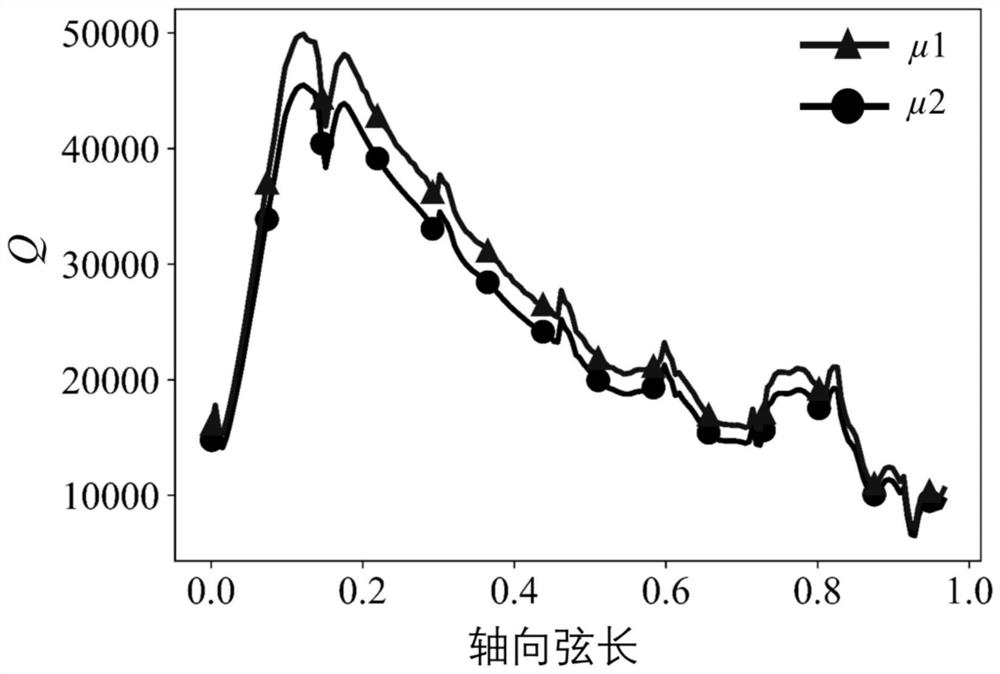

[0043] 1. Rough polynomial chaotic model and sparse sample point generation module, input random variables to be studied to generate sample point distribution. In this embodiment, the depth of the groove, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com