Multi-channel sample adding arm

A sample loading arm and multi-channel technology, which is applied to the analysis of materials and instruments, can solve the problems of unusable, single sample loading arm, and low flexibility, and achieve the effect of increasing the transfer function, saving platform space, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

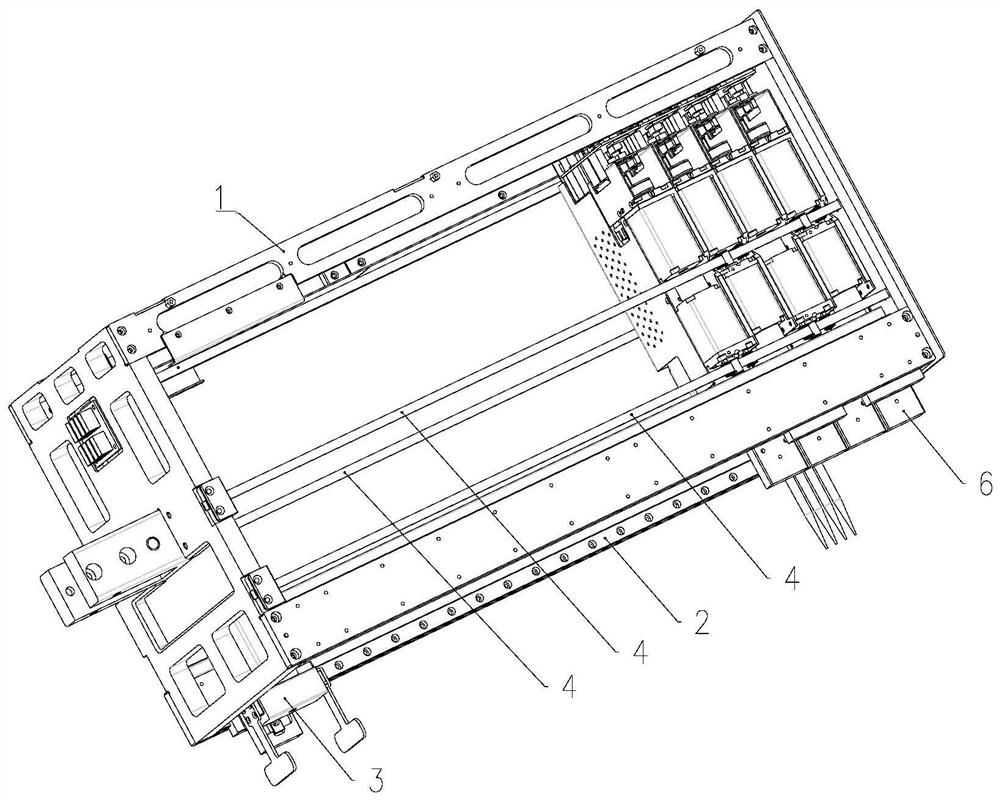

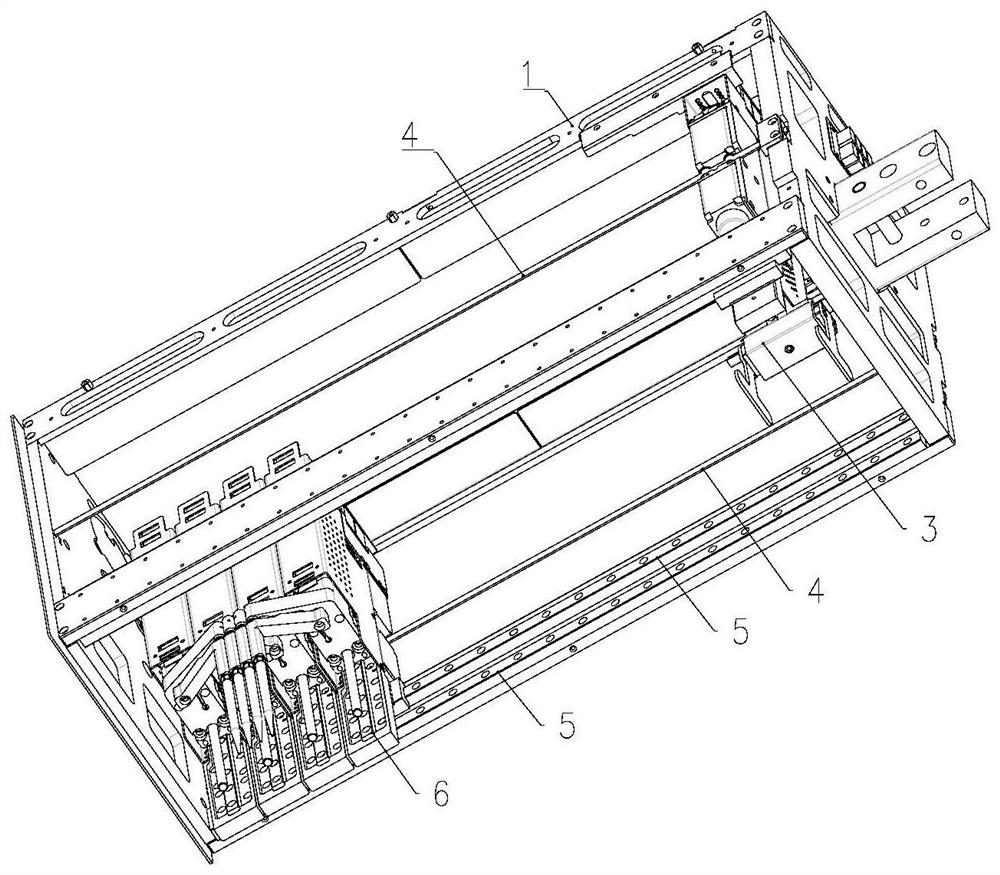

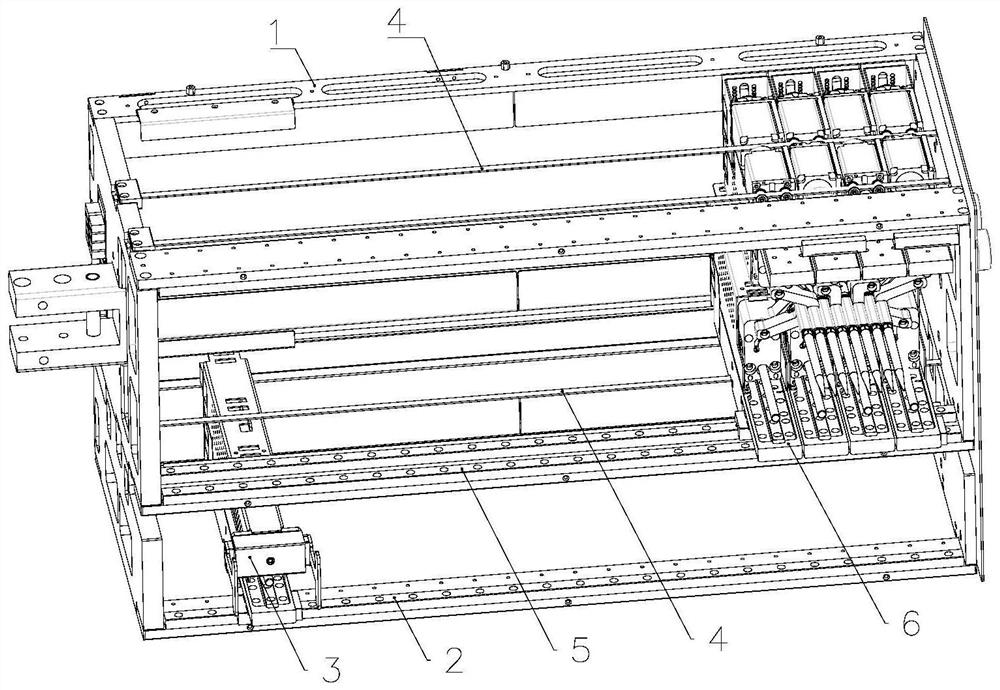

[0034] In order to describe technical characterictic of the present invention and realized purpose and effect in detail, further describe below in conjunction with accompanying drawing:

[0035] Such as Figure 1-10As shown, a multi-channel sample loading arm includes a frame 1, a sample loading module guide rail 5 and a timing belt 4 are installed in parallel on one side of the frame 1, and several sample loading modules are installed on the sample loading module guide rail 5 and the timing belt 4 6. The sample adding module 6 includes a sample adding module bracket 61, one side of the sample adding module bracket 61 is fixed on the slider of the sample adding module guide rail 5, and the fixed side of the sample adding module bracket 61 is installed with a sample adding module in the Z direction. The drive motor 63 and the Y-direction drive module 7, the other side is equipped with a sample loading module Z-direction sliding mechanism 62, the Y-direction movement module 7 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com