Preparation method of sensitive element of humidity sensor

A humidity sensor and sensitive element technology, which is applied in the direction of instruments, scientific instruments, and material analysis using radiation diffraction, etc., to achieve good effect, uniform appearance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A method for preparing a sensitive element of a humidity sensor, comprising the steps of:

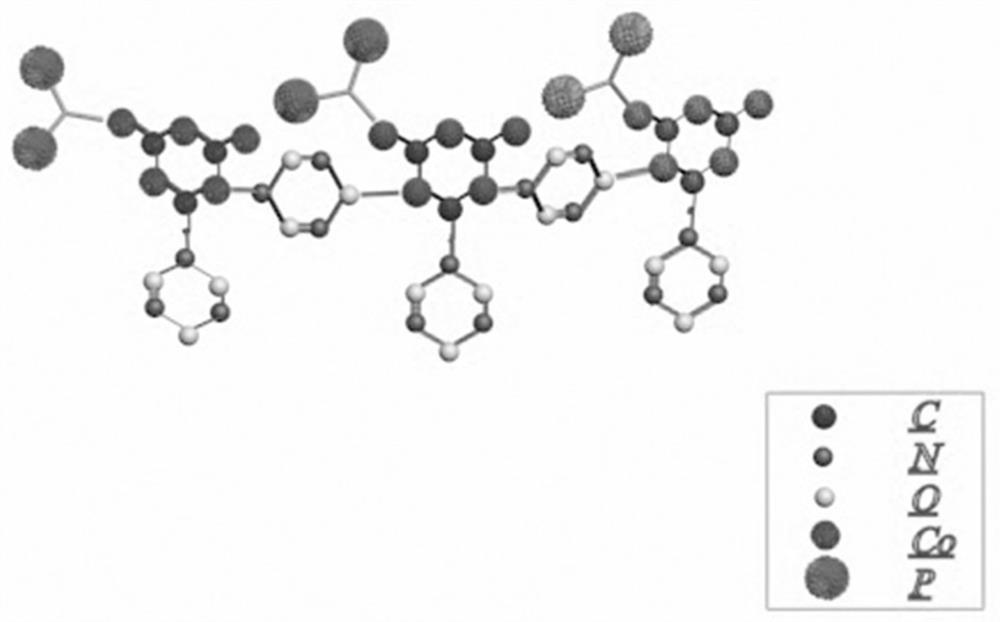

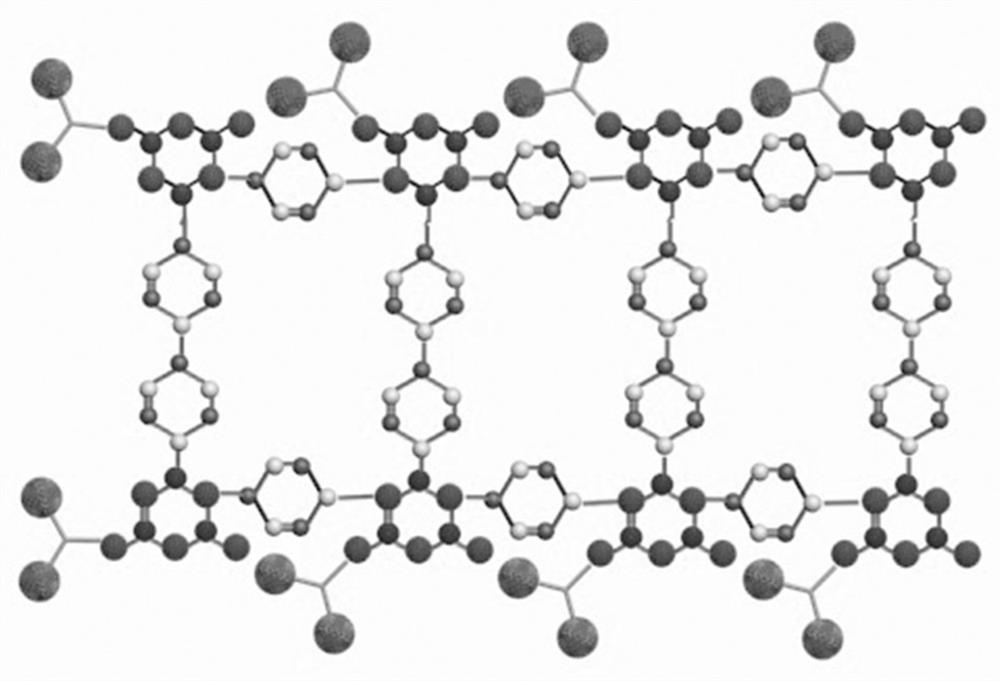

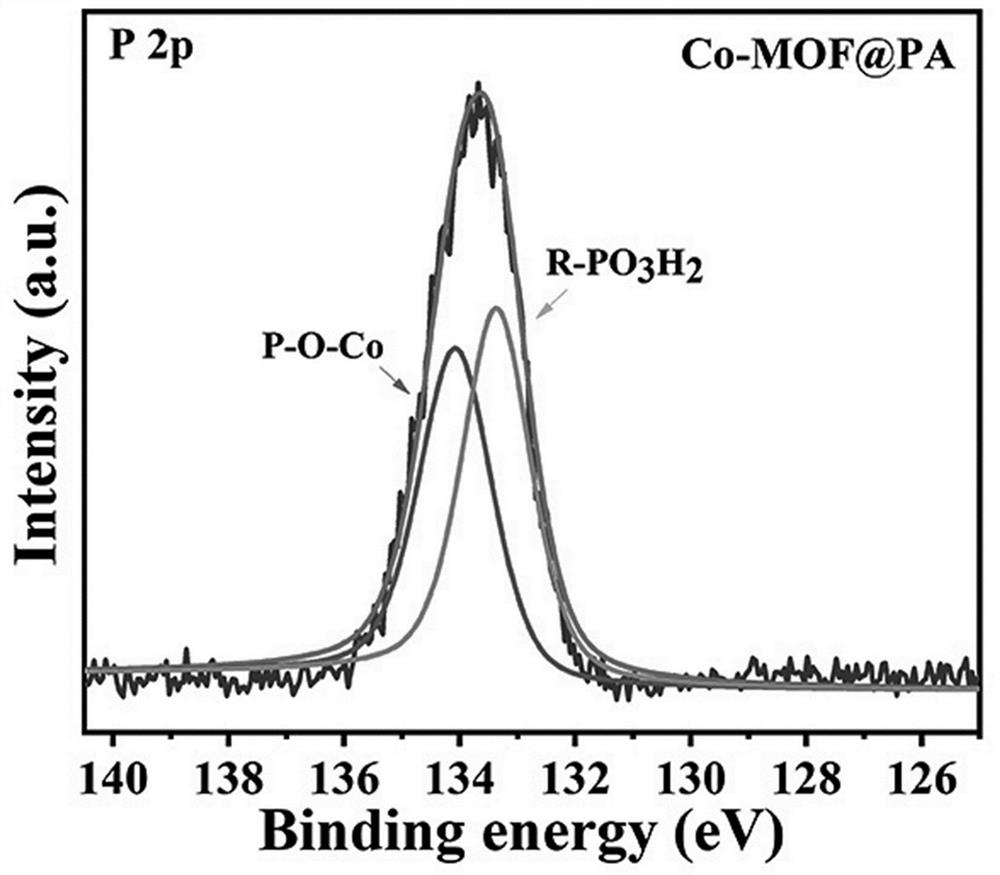

[0035] (1) Take cobalt nitrate hexahydrate, 4,4'-bipyridyl and polyvinylpyrrolidone as raw materials, measure these three raw materials with a molar ratio of 1:0.35-0.40:2.50-3, mix them and dissolve them in N, N - In the mixed solution of dimethylformamide and absolute ethanol, the volume ratio of N,N-dimethylformamide and absolute ethanol is 3:1, and 7-8ml of absolute ethanol is added for every 1mg of cobalt nitrate hexahydrate and mixed solution, stirred for 10-20 minutes to obtain mixed solution A; wherein the average molecular weight of polyvinylpyrrolidone is 1,300,000;

[0036] (2) Dissolve meso-tetrakis(4-carboxyphenyl)porphine in a mixed solution of N,N-dimethylformamide and absolute ethanol, N,N-dimethylformamide and absolute ethanol The volume ratio is 3:1, wherein the mol ratio of meso-tetrakis(4-carboxyphenyl)porphin to absolute ethanol is 1:2.5-4, stir...

Embodiment 2

[0041] Embodiment 2 A method for preparing a sensitive element of a humidity sensor, comprising the steps of:

[0042](1) Take cobalt nitrate hexahydrate, 4,4'-bipyridyl and polyvinylpyrrolidone as raw materials, measure these three raw materials at a molar ratio of 1:0.37:2.70, mix them and dissolve them in N,N-dimethyl In the mixed solution of formamide and absolute ethanol, the volume ratio of N,N-dimethylformamide and absolute ethanol is 3:1, wherein 7.5ml of absolute ethanol mixed solution is added to every 1mg of cobalt nitrate hexahydrate, and stirred for 15 minutes , to obtain mixed solution A; wherein the average molecular weight of polyvinylpyrrolidone is 1,300,000;

[0043] (2) Dissolve meso-tetrakis(4-carboxyphenyl)porphine in a mixed solution of N,N-dimethylformamide and absolute ethanol, N,N-dimethylformamide and absolute ethanol The volume ratio of the mixture is 3:1, and the molar ratio of meso-tetrakis(4-carboxyphenyl)porphin to absolute ethanol is 1:3, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com