Novel resin material extensibility testing device

A resin material and testing device technology, which is applied in the direction of testing the ductility of materials, measuring devices, and analyzing materials, etc., can solve the problems of low safety, time-consuming and labor-intensive breaking, etc., and achieve convenient data statistics, high safety, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

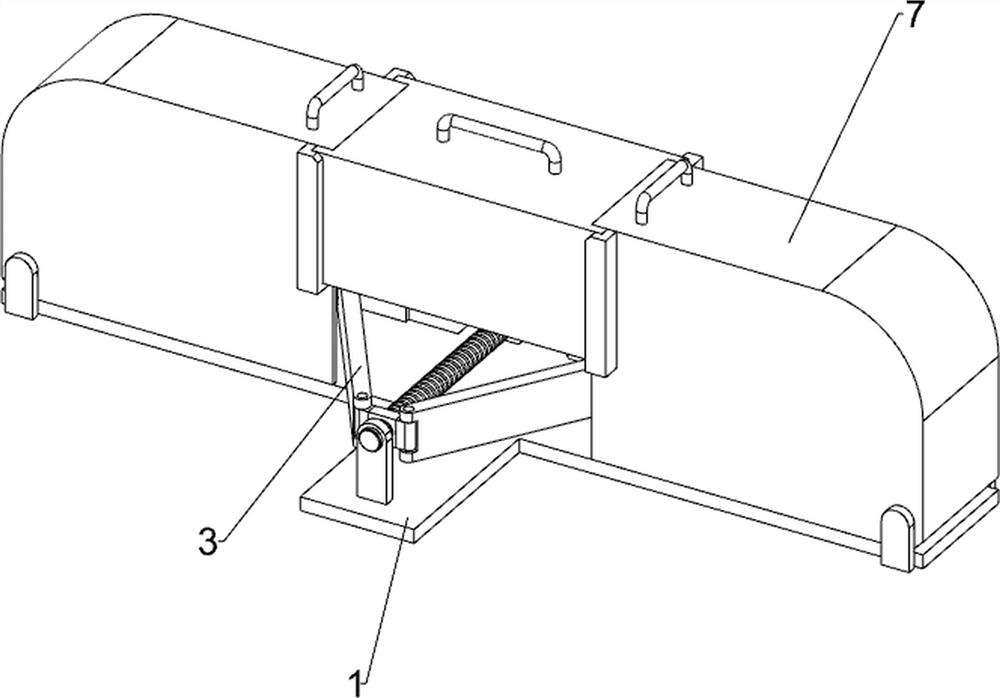

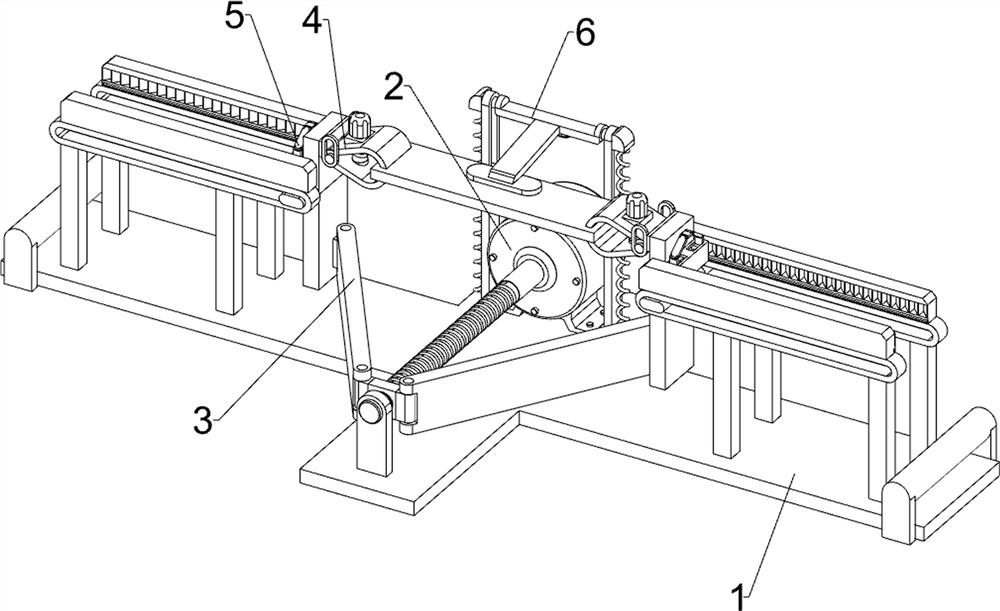

[0027] A new type of resin material stretch testing device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a motor 2, a stretching mechanism 3 and a clamping mechanism 4. A motor 2 is arranged in the middle of the top rear side of the bottom plate 1, and a stretching mechanism 3 is arranged between the top of the bottom plate 1 and the output shaft of the motor 2. The stretching mechanism 3 is provided with a clamping mechanism 4 .

[0028] The stretching mechanism 3 includes a first support column 31, a worm screw 32, a push block 33, a rotating rod 34, a moving block 35, a second support column 36 and a first slide rail 37, and the middle part of the top front side of the bottom plate 1 is provided with a first support Column 31, first support column 31 top rotation is provided with worm screw 32, and worm screw 32 rear side is connected with motor 2 output shaft, and worm screw 32 is threadedly provided with push block 33, a...

Embodiment 2

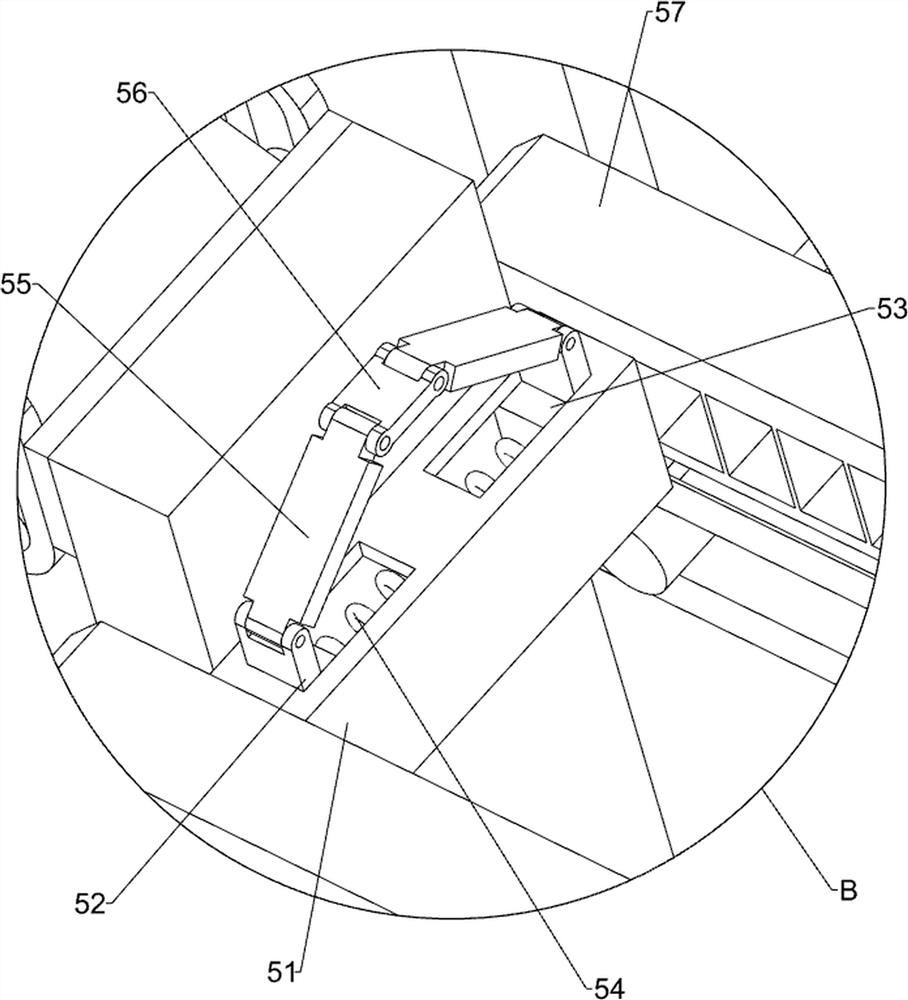

[0032] On the basis of Example 1, such as Figure 5 , Figure 6 and Figure 7 As shown, a positioning mechanism 5 is also included, and the positioning mechanism 5 includes a moving sleeve 51, a first connecting block 52, a clamping block 53, a first spring 54, a second connecting block 55, a third connecting block 56 and a clamping rail 57, The top of the first slide rail 37 is provided with a catch rail 57, and a movable cover 51 is slidably provided between the catch rails 57 on the same side. The bottom of the connecting block 52 is provided with a block 53, the block 53 is slidably connected with the moving sleeve 51, the block 53 is matched with the rail 57, and a first spring 54 is arranged between the opposite side of the block 53 and the moving sleeve 51 The upper part of the first connecting block 52 is rotatably provided with a second connecting block 55, and the second connecting blocks 55 on the same side are all rotatably provided with a third connecting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com