Coal mine rapid and automatic flame-retardant explosion-proof device and automatic detection control system thereof

An automatic detection and control system technology, applied in safety devices, mining equipment, earthwork drilling, etc., can solve the problems of prolonging the trigger time, affecting flame retardant and explosion proof, reducing the reserve of fire extinguishing powder, etc., to reduce the risk of secondary explosion , Eliminate the interference of human factors, improve the effect of safety and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

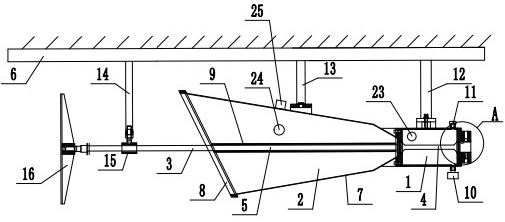

[0049] This embodiment is a one-way receiving and one-way eruption mode. Such as figure 1 , Image 6 , Figure 11-12 As shown, a coal mine rapid automatic flame-retardant explosion-proof device and its automatic detection and control system include a high-pressure gas storage bin 1, an eruption powder storage bin 2, a trigger assembly 3 and an automatic detection and control system. The trigger assembly 3 passes through the eruption Inside the powder storage bin 2, the high-pressure gas storage bin 1 is arranged outside the eruption powder storage bin 2, the high-pressure gas storage bin 1 is provided with a piston 4, and the trigger assembly 3 includes a transfer rod 5, and the piston 4 is connected to the transfer rod 5. The high-pressure gas storage bin 1, the eruption powder storage bin 2 and the trigger assembly 3 are installed on the top of the coal mine roadway through the hanging device 6.

[0050] Both ends of the piston 4 have the same diameter and the piston 4 ca...

no. 2 example

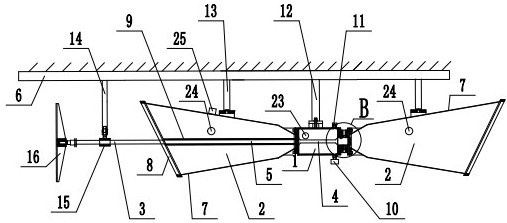

[0066] This embodiment is a one-way receiving and two-way eruption mode. Such as figure 2 , Figure 7 , Figure 11-12 As shown, one end of the transmission rod 5 is provided with a shock wave receiving portion 16 for receiving a one-way shock wave; different from the first embodiment, the high-pressure gas storage bin 1 is connected to two symmetrically distributed eruption powder storage bins 2 , two symmetrically distributed eruption powder storage bins 2 spray in opposite directions, and after triggering, the fire extinguishing powder is erupted in two directions, which increases the effective protection range of the fire extinguishing powder compared with the one-way eruption method, and achieves a two-way explosion-proof effect.

[0067] Such as Figure 7As shown, the number of the steel ball limiting groove 18 is one, and the steel ball limiting groove 18 is closer to the high-pressure gas storage bin 1 than the steel ball storage groove 17 .

[0068] figure 2 Rec...

no. 3 example

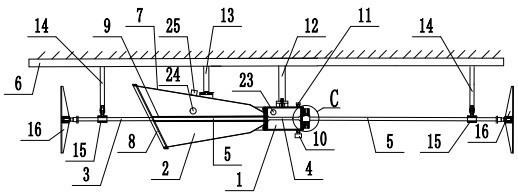

[0070] This embodiment is a two-way reception and one-way eruption mode, which can be applied to roadways where the source of the explosion direction is uncertain. Such as image 3 , Figure 8 , Figure 11-12 As shown, both ends of the transmission rod 5 are provided with shock wave receivers 16 for bidirectionally receiving shock waves; the high-pressure gas storage chamber 1 is connected to an eruption powder storage chamber 2, which emits fire extinguishing powder in one direction after being triggered.

[0071] Such as Figure 8 As shown, the number of steel ball limiting grooves 18 on the surface of each piston 4 is 2, and the two steel ball limiting grooves 18 are symmetrically arranged with respect to the steel ball storage groove 17, and are used to limit the position of the piston 4 after two-way triggering. bit.

[0072] image 3 For bi-directional reception of the left jet, it can also be set to bi-directional reception of the right jet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com