Acetylene production process

A production process, acetylene generator technology, applied in the field of acetylene production process, can solve problems such as insufficient contact, achieve the effect of improving the degree of reaction, increasing the movement path, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

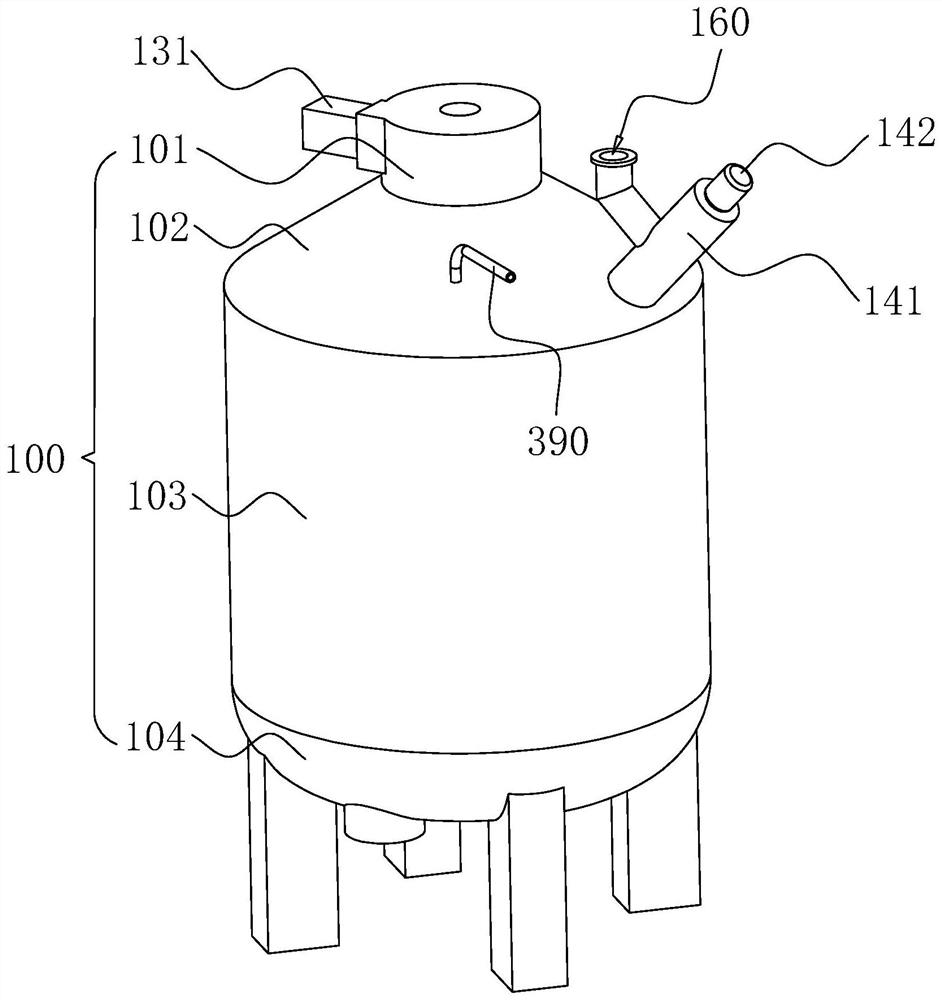

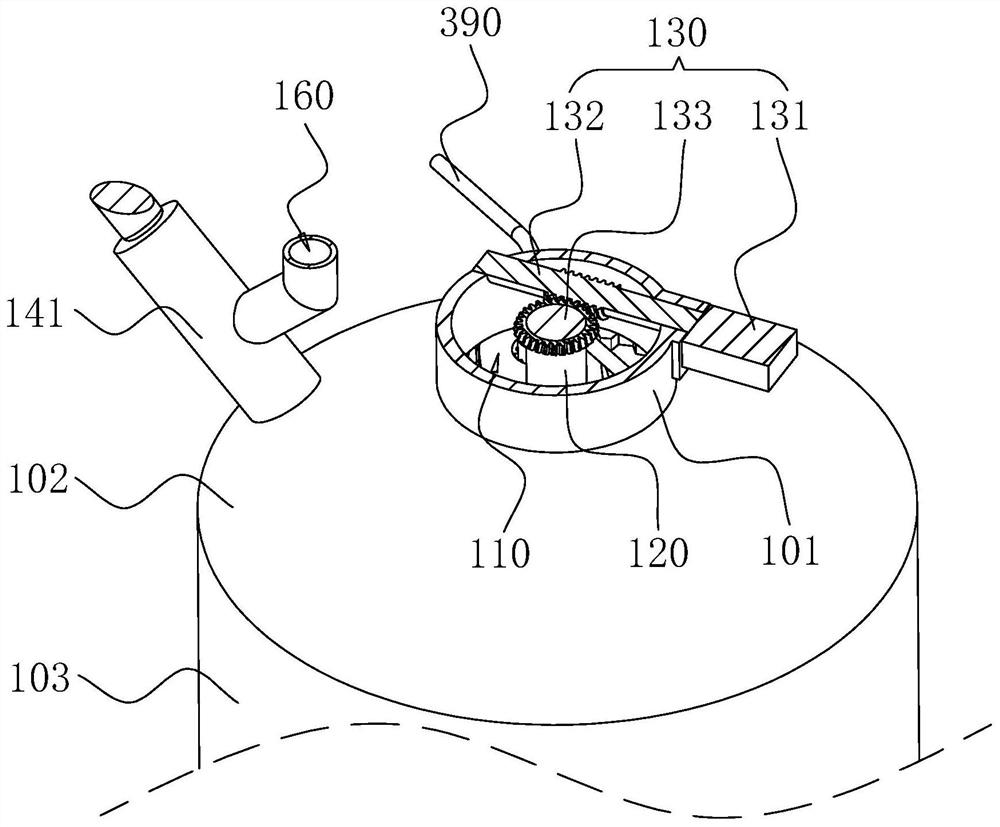

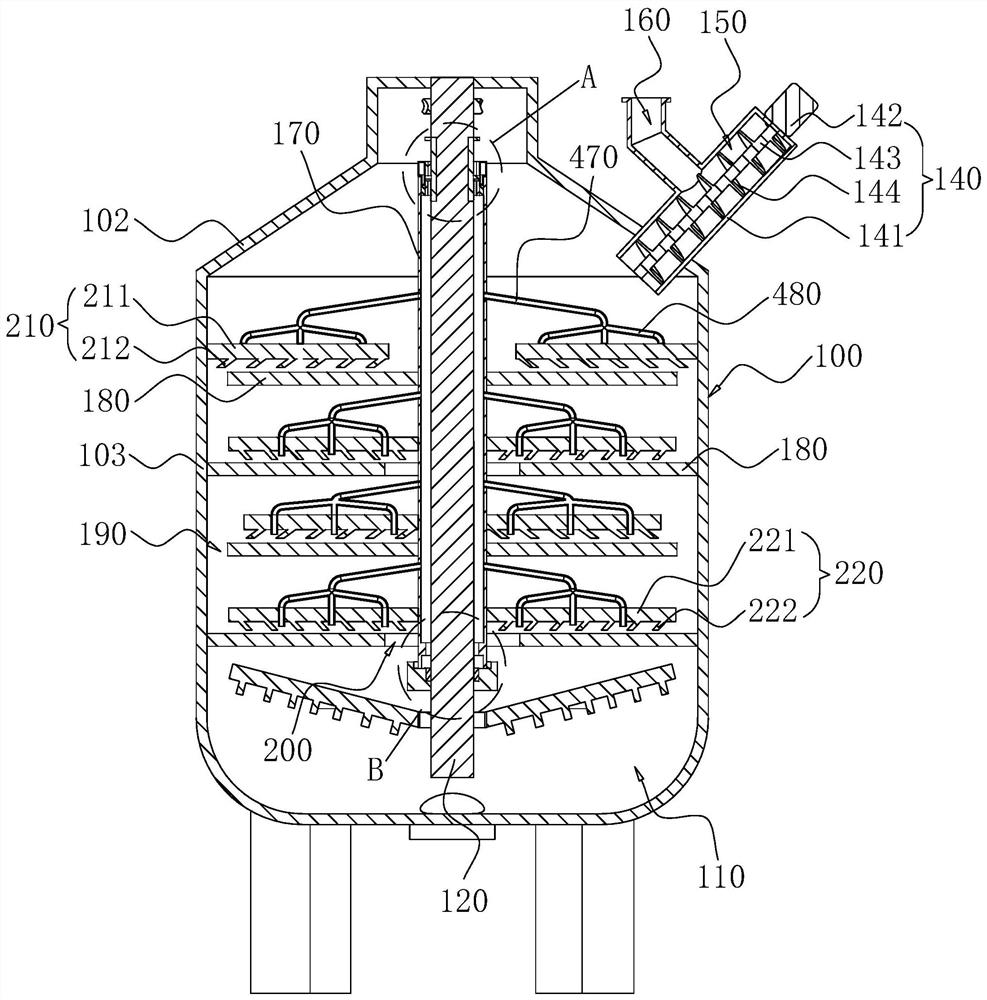

[0051] The following is attached Figure 1-5 The application is described in further detail.

[0052] The embodiment of the present application discloses an acetylene production process, comprising the following process steps:

[0053] S1, raw material processing, use jaw crusher to crush large calcium carbide raw materials, crush large calcium carbide raw materials to medium calcium carbide raw materials of 180-250mm, and then use cone crusher to crush medium calcium carbide raw materials into 50 -80mm small pieces of calcium carbide raw materials, the crushed small pieces of calcium carbide raw materials are added to the high-level calcium carbide silo and nitrogen is introduced;

[0054] S2, feeding, adding small pieces of calcium carbide raw materials treated with nitrogen in the high-level calcium carbide silo into the hopper, and the calcium carbide is transported into the acetylene generator through the hopper;

[0055] S3, reaction, start the acetylene generator and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com