Preparation method of super-tough composite modified nylon master batch

A composite modification and nylon technology, applied in the field of nylon material modification, to achieve the effects of simple process, good mass production and application, and excellent puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

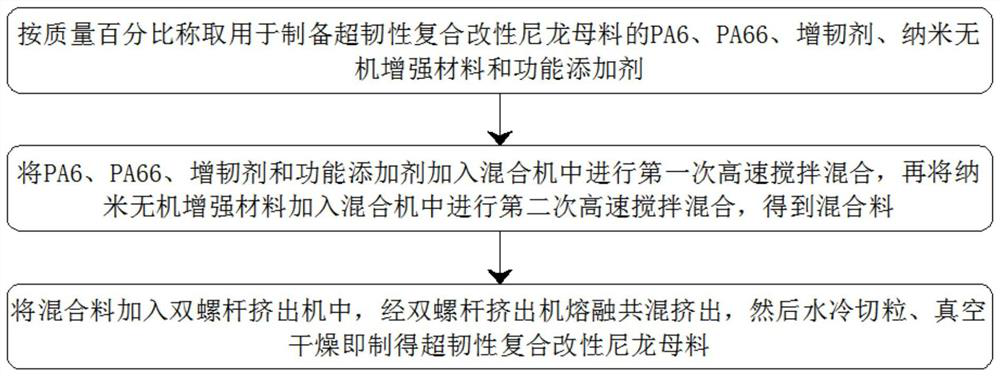

[0026] A preparation method for a super-tough composite modified nylon masterbatch, comprising the steps of:

[0027] S1. Take PA6, PA66, toughening agent, nano-inorganic reinforcing material and functional additives for preparing super-toughness composite modified nylon masterbatch by mass percentage;

[0028] S2. Add PA6, PA66, toughening agent and functional additives into the mixer for the first high-speed stirring and mixing, and then add the nano-inorganic reinforcing material into the mixer for the second high-speed stirring and mixing to obtain a mixture;

[0029] S3. Put the mixture into the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, then water-cooled, pelletize, and vacuum-dry to obtain a super-tough composite modified nylon masterbatch.

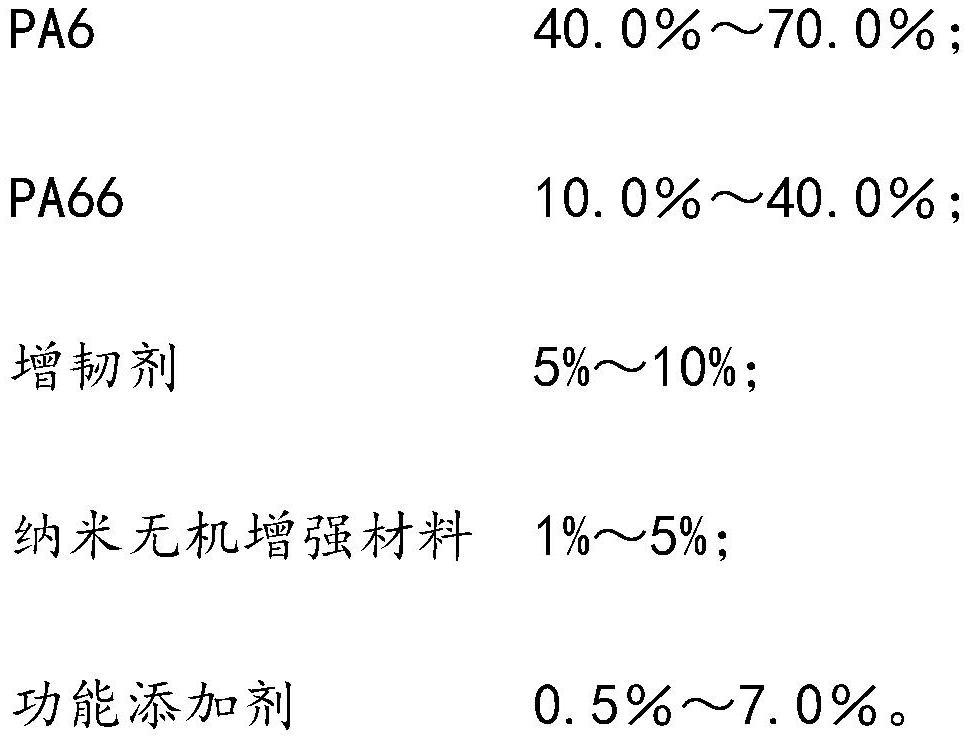

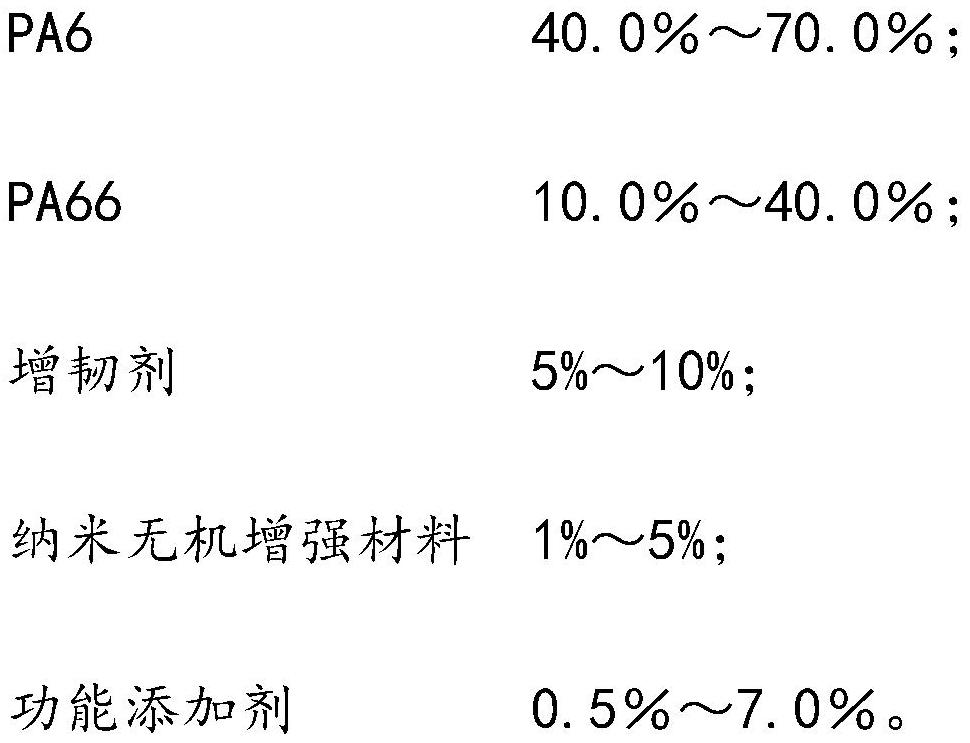

[0030] As a technical preferred solution of the present invention, the formula of the super-tough composite modified nylon masterbatch by mass percentage is as follows: 40.0% content of PA6, 38.0%...

Embodiment 2

[0040] A preparation method for a super-tough composite modified nylon masterbatch, comprising the steps of:

[0041] S1. Take PA6, PA66, toughening agent, nano-inorganic reinforcing material and functional additives for preparing super-toughness composite modified nylon masterbatch by mass percentage;

[0042] S2. Add PA6, PA66, toughening agent and functional additives into the mixer for the first high-speed stirring and mixing, and then add the nano-inorganic reinforcing material into the mixer for the second high-speed stirring and mixing to obtain a mixture;

[0043] S3. Put the mixture into the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, then water-cooled, pelletize, and vacuum-dry to obtain a super-tough composite modified nylon masterbatch.

[0044] As a technical preferred solution of the present invention, the formula of the super-tough composite modified nylon masterbatch by mass percentage is as follows: 55% content of PA6, 30% con...

Embodiment 3

[0054] A preparation method for a super-tough composite modified nylon masterbatch, comprising the steps of:

[0055] S1. Take PA6, PA66, toughening agent, nano-inorganic reinforcing material and functional additives for preparing super-toughness composite modified nylon masterbatch by mass percentage;

[0056] S2. Add PA6, PA66, toughening agent and functional additives into the mixer for the first high-speed stirring and mixing, and then add the nano-inorganic reinforcing material into the mixer for the second high-speed stirring and mixing to obtain a mixture;

[0057] S3. Put the mixture into the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, then water-cooled, pelletize, and vacuum-dry to obtain a super-tough composite modified nylon masterbatch.

[0058] As a technical preferred solution of the present invention, the formula of the super-tough composite modified nylon masterbatch in terms of mass percentage is as follows: 70.0% content of P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com