Production method of vitamin B6

A production method and vitamin technology, applied in the direction of organic chemistry and the like, can solve problems such as black tar substances, and achieve the effects of reducing organic matter, significant economic benefits, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

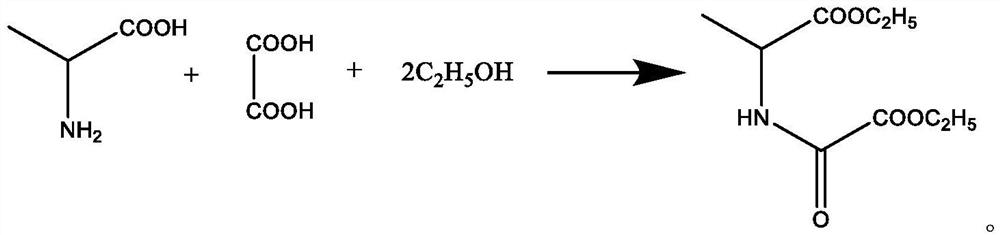

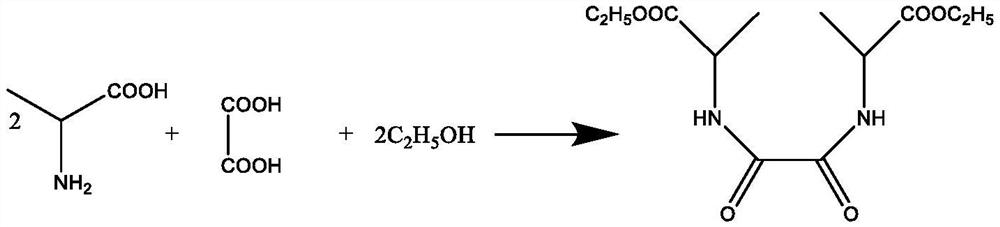

Method used

Image

Examples

Embodiment 1

[0045] This example provides a production method of vitamin B6. On the basis of the existing technology, the following additions are added: purification of the crude ester acyl product obtained from the normal ester acylation reaction, and the separation of the by-product 2,2'-grass two Ethyl amidodipropionate, and the by-product is hydrolyzed for reuse. The specific steps are:

[0046] (1) Get 3000g of ester acylation crude product (about 89~92% of gas phase purity) of ester acylation reaction and recovery finished benzene, ethanol, diethyl oxalate, drop in the distillation bottle, depressurize to 10~100pa with oil pump, Slowly raise the temperature and rectify, and according to the different temperatures at the top of the tower, collect about 180g of the front fraction before 106°C (this fraction is applied to the normal ester acylation reaction of the next batch), and about 2580g of the normal fraction between 106 and 110°C (ester Pure acyl product with a purity of over 98...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com