Two-way vent valve of inner floating roof

A two-way ventilation valve and inner floating roof technology, applied in the direction of containers, packaging, transportation and packaging, etc., can solve problems such as unsmooth travel, inability to adjust gas and pressure, difficult to open the cover plate 13, etc., to reduce the area of friction , Improve sliding smoothness, reduce mutual friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

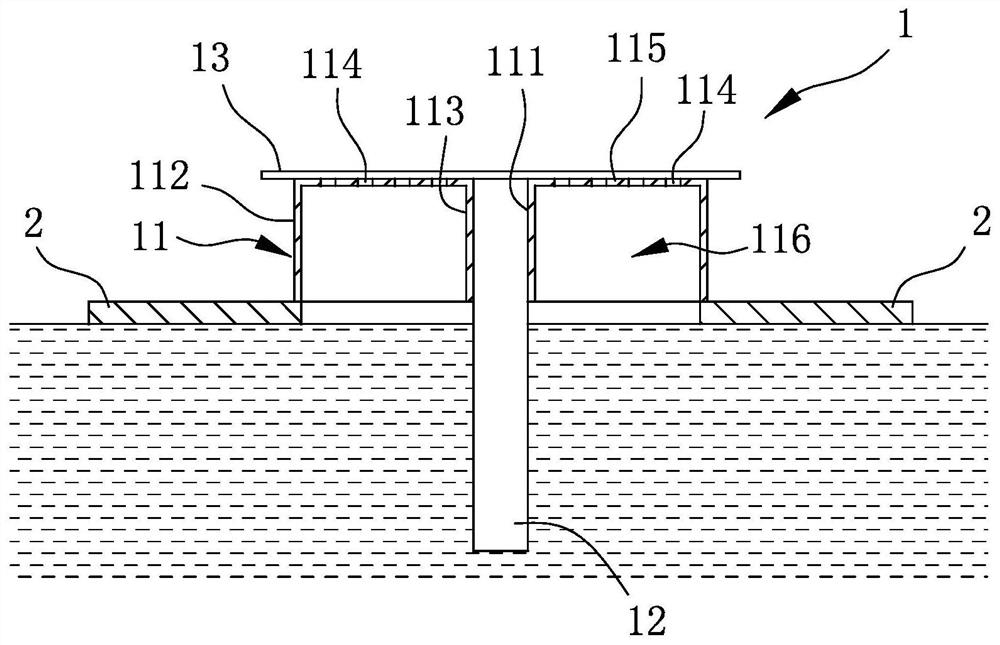

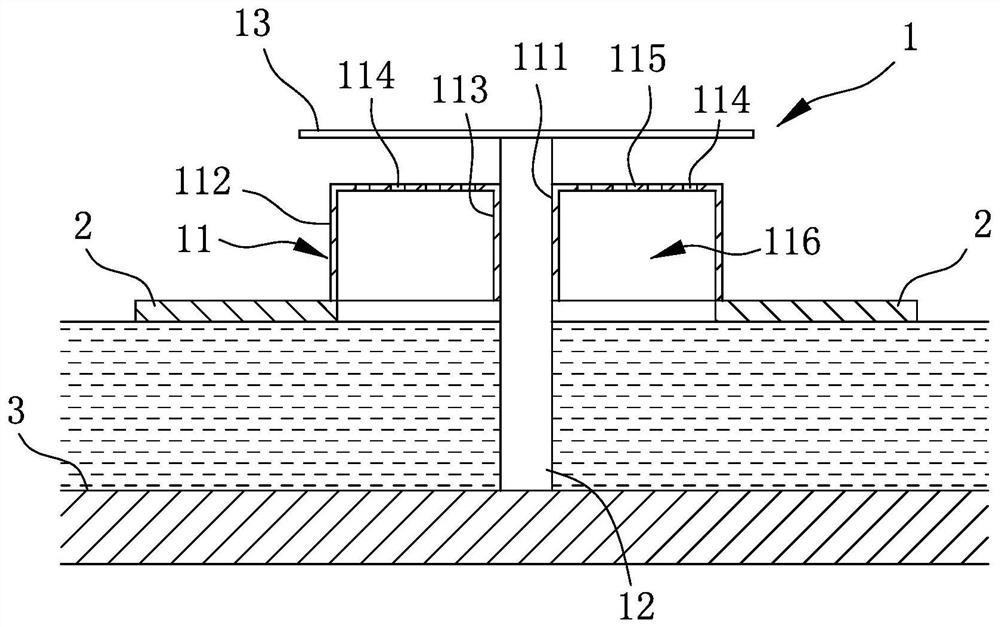

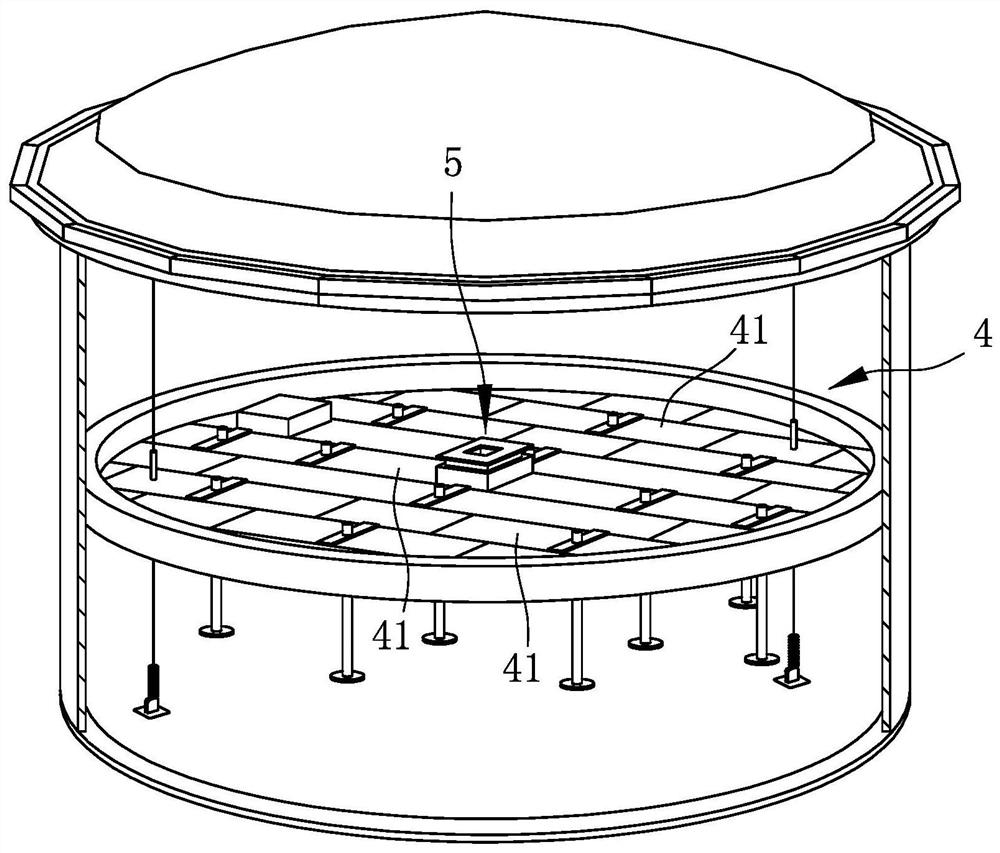

[0025] see image 3 , Figure 4 ,and Figure 5 , an embodiment of the ventilation valve 5 of the inner floating roof 4 of the present invention is suitable for being arranged on an inner floating roof 4 . The ventilation valve 5 includes an outer frame base 51 fixed on the inner floating roof 4, a ventilation hole box 52 surrounded by the outer frame base 51 and forming a plurality of air holes 521, and a ventilation hole box 52 fixed on the outer frame base 51. A sealing cover 53 located on the top surface of the vent box 52 and located above the outer frame base 51, a floating box 54 located below the sealing cover 53, a plurality of air holes disposed on the outer frame base 51, the ventilation holes The sliding member 55 between the box 52 and the floating box 54 , and a plurality of guiding members 56 disposed between the outer frame base 51 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com