Electrolyte directional controllable electrolytic milling machining device and machining process thereof

A technology of milling processing and electrolyte, which is applied in the direction of electric processing equipment, electrochemical processing equipment, and the supply of processing working media. problem, to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

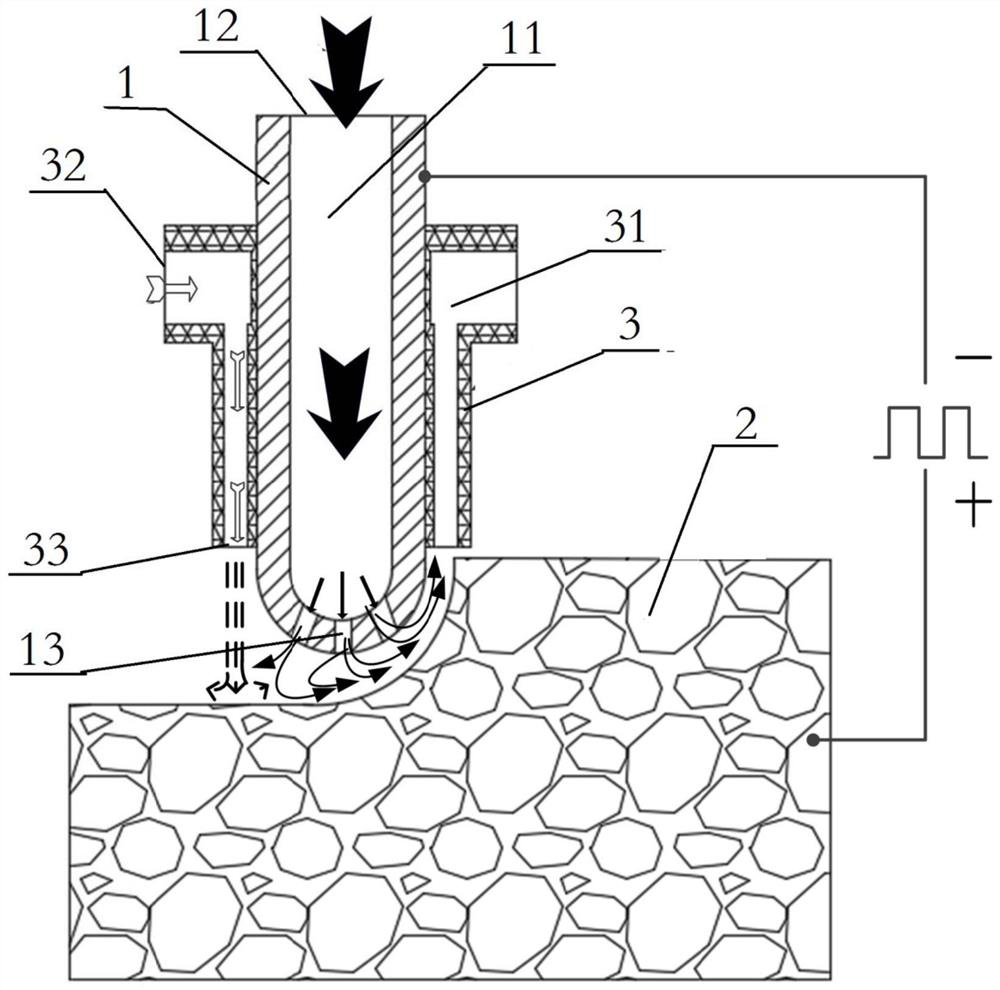

[0030] Such as figure 1 As shown, an electrolytic milling device with controllable electrolyte orientation includes a power supply and a tubular tool electrode 1, the negative pole of the power supply is connected to the tool electrode 1, the positive pole of the power supply is connected to the workpiece 2, and a power supply is provided inside the tool electrode 1. The liquid chamber 11 where the liquid solution flows, the two ends of the tool electrode 1 are respectively provided with a liquid inlet 12 and a liquid outlet 13 communicating with the liquid chamber 11, a number of nozzles 3 are fixed in a fixed array around the tool electrode 1, and the nozzles 3 are provided with high pressure The gas chamber 31 for gas circulation, the two ends of several nozzles 3 are respectively provided with air inlets 32 and air outlet holes 33 communicating with the gas chamber 31, and several air outlet holes 33 are fixedly arrayed around the liquid outlet hole 13, and the liquid outle...

Embodiment 2

[0040] This embodiment is the processing technology of the above-mentioned electrolytic milling processing device with controllable electrolyte orientation, including the following steps:

[0041] S1: fix the nozzle 3 array around the tool electrode 1;

[0042] S2: Connect the tool electrode 1 to the negative pole of the power supply, and the workpiece 2 to be processed to the positive pole of the power supply;

[0043] S3: Pass the electrolyte from the liquid inlet 12 to the liquid chamber 11 inside the tool electrode 1, and the electrolyte is sprayed out through the liquid outlet 13; selectively open a number of nozzles 3, and pass into a number of nozzles 3 from the air inlet 32 High-pressure gas, the high-pressure gas is ejected from several air outlet holes 33;

[0044] S4: Turn on the power, control the tool electrode 1 to move along the machining path, and realize the electrolytic milling process with controllable orientation of the electrolyte.

[0045] In the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com