Process for removing dust and impurities from traditional Chinese medicinal materials

A technology for traditional Chinese medicinal materials and medicinal materials, which is applied in the cleaning method of tools, the separation of solids from solids by air flow, and the separation of solids, etc., can solve the problems of excessive dust, poor dust removal effect, and difficulty in removing medicinal materials, and achieves increased Economic benefits, avoid clogging or scattering, improve production and processing efficiency and the effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

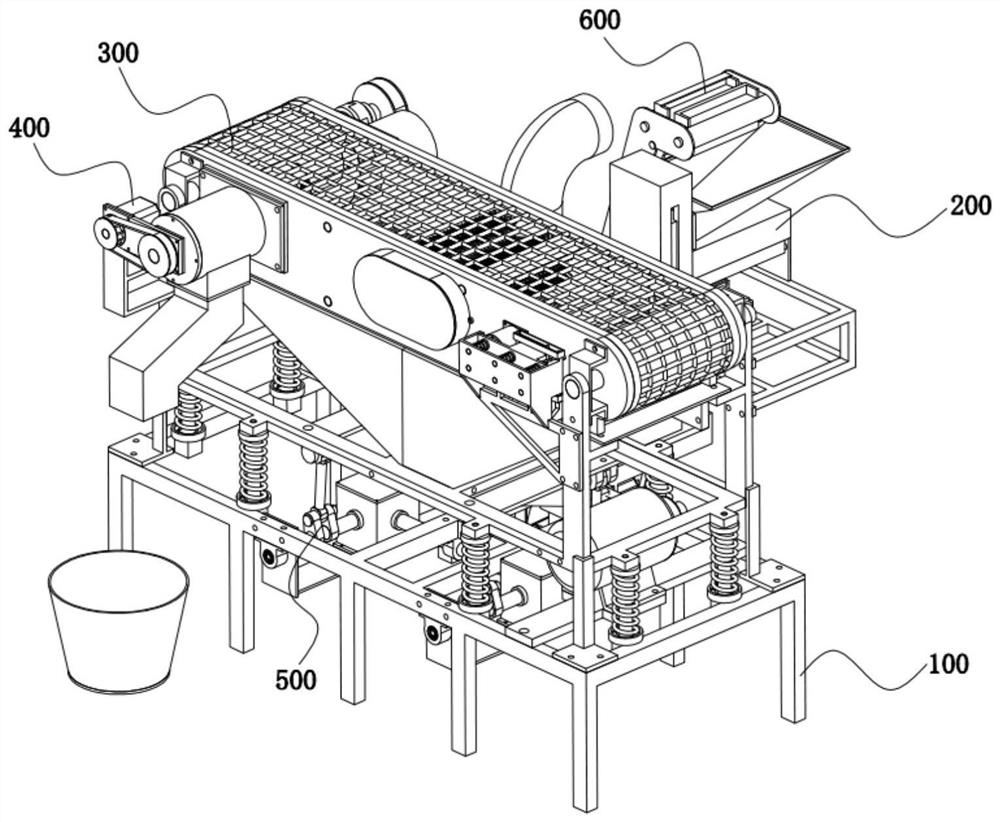

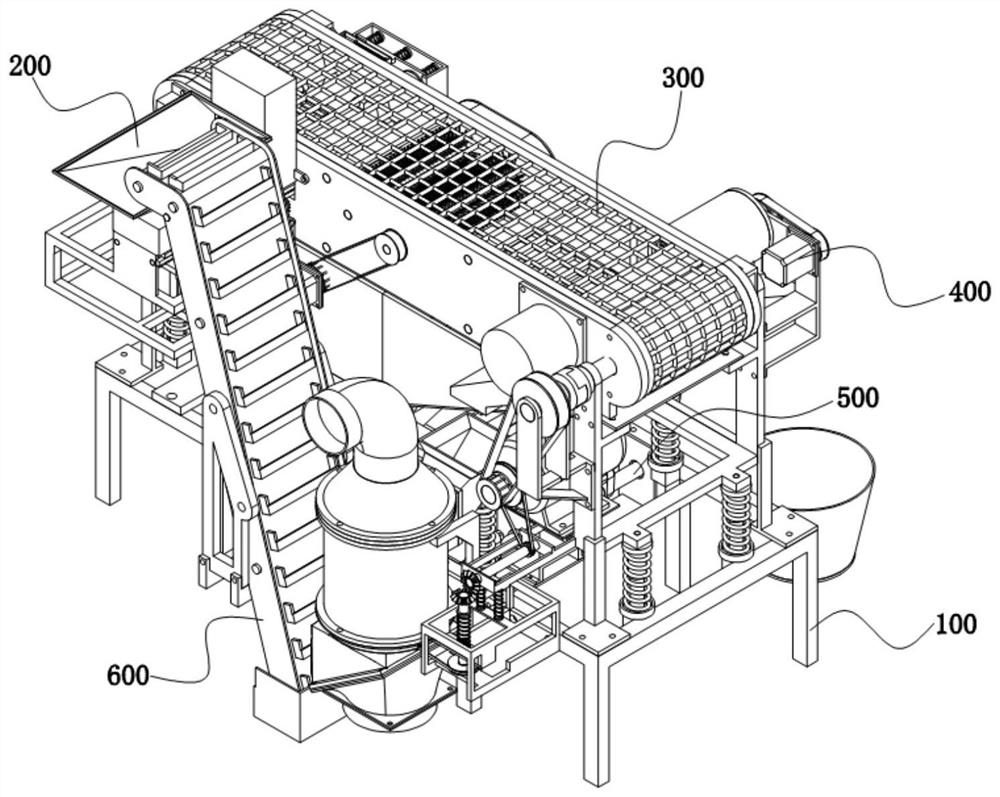

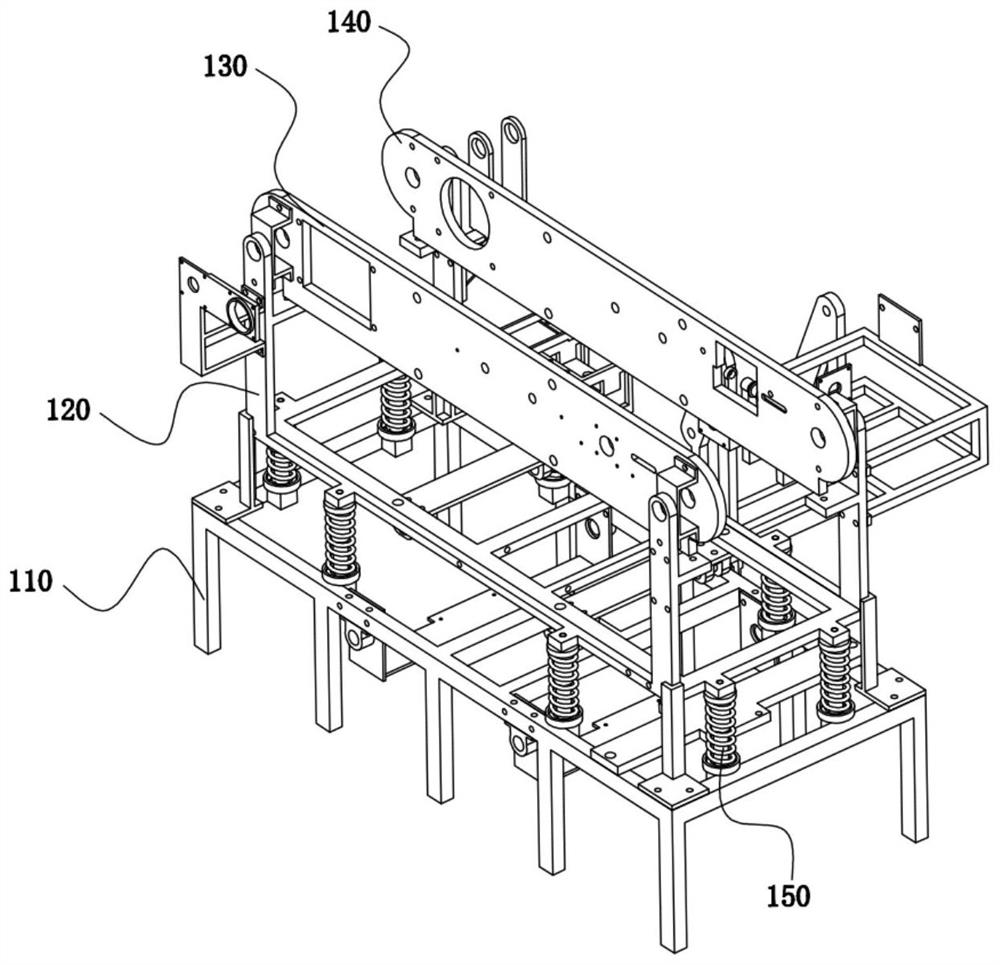

[0080] An automatic dedusting and impurity removal equipment for medicinal materials, which includes a mounting frame body 100, on which a feeding device 200, a cleaning device 300, a discharging device 400, a moving device 500, and a transfer device 600 are installed. The device 200 is used to introduce the medicinal materials carrying dust and impurities into the cleaning device 300, the cleaning device 300 is used to remove dust and impurities from the imported medicinal materials, and the discharge device 400 is used to clean the medicinal materials that have not been cleaned Exporting for cleaning again and transporting and collecting the cleaned medicinal materials, the moving device 500 is used to assist the separation of medicinal materials and impurities and dust through motion, and the transfer device 600 is used to transport the uncleaned medicinal materials Import into the feeding device 200.

[0081] When the equipment is working, the operator puts the medicinal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com