SMILE lens staining low-temperature separation, application and use method thereof

A separation liquid and lens technology, applied in the field of ophthalmic refractive surgery, can solve the problems of corneal stromal lens separation difficulties, wrong lens shovel entry, corneal incision tearing, etc., so as to alleviate secondary mechanical effects, reduce resistance, and reduce mechanical traction. The effect of pulling and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the embodiments of the present application, OBL (opaque bubble layers) refers to the aggregates of bubbles gathered between the corneal layers, and is the water vapor generated when the femtosecond laser light blasts in the tissue. and CO 2 Formed by the diffusion of gaps between collagen fibers above or below the cutting plane, it is an undesirable clinical phenomenon that occurs during femtosecond laser corneal surgery.

[0019] In the embodiment of this application, DLK (diffuse lamellar keratitis) refers to non-infectious, diffuse subcap inflammatory cell infiltration between corneal layers after laser corneal refractive surgery. After 24 hours, it showed as fine white particle-like turbidity.

[0020] The application and its beneficial effects will be further described in detail below in conjunction with the embodiments.

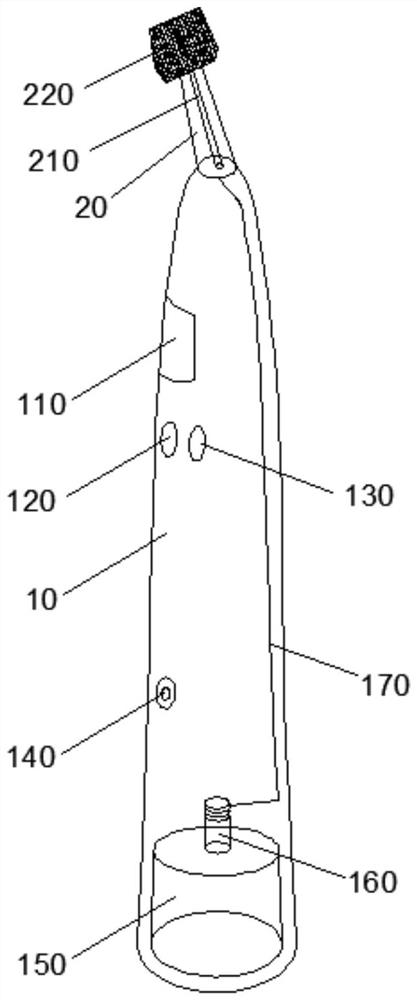

[0021] This embodiment provides a low-temperature separation liquid for SMILE lens dyeing. The SMILE lens dyeing l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com