Preparation method of pungent and spicy gluten

A preparation method and technology of spicy strips, which are applied in the field of spicy flavor preparation of spicy strips, can solve problems such as loss of umami taste and harmfulness to human health, and achieve the effects of reducing consumption, good conditioning effect, and increasing spicy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

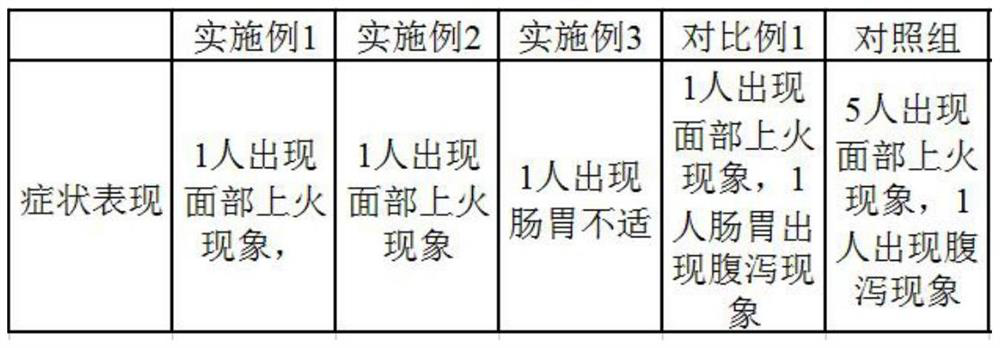

Examples

Embodiment 1

[0022] A method for preparing spicy strips with spicy flavor, comprising the following steps:

[0023] Step 1. Preparation of seasoning oil: Weigh chili powder, cumin powder, Chinese prickly ash, grass fruit, cinnamon bark, salt, star anise, granulated sugar, Polygonum water, clove basil, and eagle tea and grind them into fine powder respectively, put the chili powder into the pre- Soak in heated high-temperature edible oil for 3 minutes. The temperature of the preheated edible oil is 170°C, then cool it down to 80°C with ice water, add cumin powder, pepper, grass fruit, cinnamon bark, and star anise, and simmer for 20 minutes. Then lower the temperature to 50°C, add salt, granulated sugar, Polygonum polygonum, clove basil, eagle tea, and monosodium glutamate, mix and stir, finally add highland barley wine and stir evenly to obtain seasoning oil, cool to below 40°C for later use, and each raw material is used in parts by mass Count: 5 parts of chili powder, 0.5 parts of cumin ...

Embodiment 2

[0027] A method for preparing spicy strips with spicy flavor, comprising the following steps:

[0028] Step 1. Preparation of seasoning oil: Weigh chili powder, cumin powder, Chinese prickly ash, grass fruit, cinnamon bark, salt, star anise, granulated sugar, Polygonum water, clove basil, and eagle tea and grind them into fine powder respectively, put the chili powder into the pre- Soak in heated high-temperature edible oil for 5 minutes. The temperature of the preheated edible oil is 175°C, then cool it down to 90°C with ice water, add cumin powder, pepper, grass fruit, cinnamon, and star anise, and simmer for 30 minutes. Then lower the temperature to 60°C, add salt, granulated sugar, Polygonum polygonum, clove basil, eagle tea, and monosodium glutamate, mix and stir, and finally add highland barley wine and stir evenly to obtain seasoning oil, cool to below 40°C for later use, and use parts by mass of each raw material Counting: 3 parts of chili powder, 1 part of cumin powde...

Embodiment 3

[0032] A method for preparing spicy strips with spicy flavor, comprising the following steps:

[0033] Step 1. Preparation of seasoning oil: Weigh chili powder, cumin powder, Chinese prickly ash, grass fruit, cinnamon bark, salt, star anise, granulated sugar, Polygonum water, clove basil, and eagle tea and grind them into fine powder respectively, put the chili powder into the pre- Soak in heated high-temperature edible oil for 4 minutes. The temperature of the preheated edible oil is 172°C, then cool it down to 85°C with ice water, add cumin powder, pepper, grass fruit, cinnamon, and star anise, and simmer for 25 minutes. Then lower the temperature to 55°C, add salt, granulated sugar, Polygonum polygonum, clove basil, eagle tea, and monosodium glutamate, mix and stir, and finally add highland barley wine and stir evenly to obtain seasoning oil, cool to below 40°C for later use, and use parts by mass of each raw material Count: 4 parts of chili powder, 0.8 parts of cumin powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com