Large-scale intelligent pesticide spraying device

A large-scale, intelligent technology that is applied to devices for capturing or killing insects, cutters, agricultural machinery and implements, etc. It can solve the problems of pesticide waste, weed weed entanglement and jamming of weeders, and the inability to adjust the height of weeders according to terrain changes and other problems, to achieve the effect of preventing grass clippings from splashing and saving usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

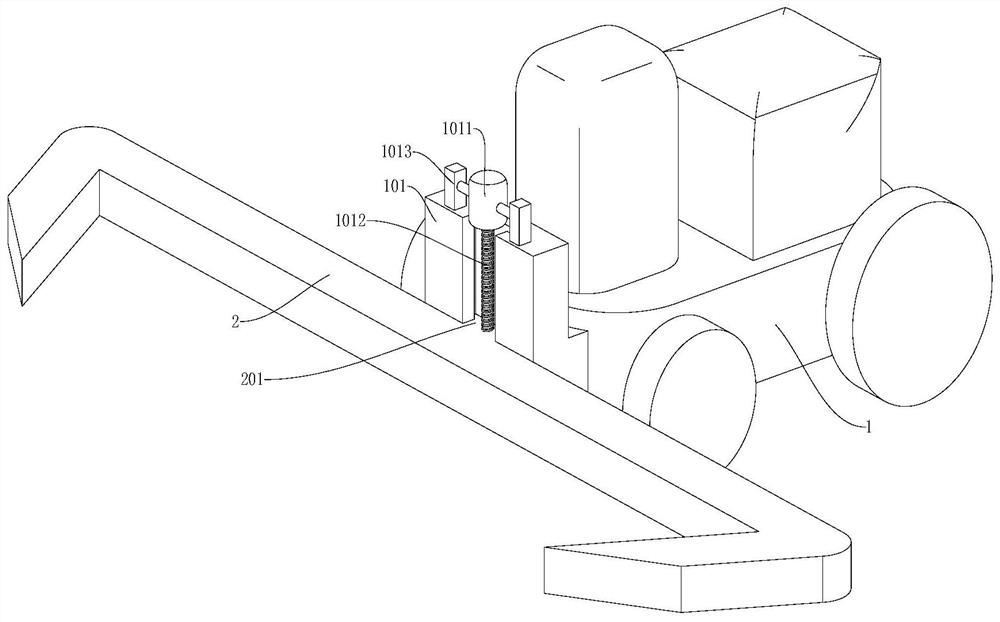

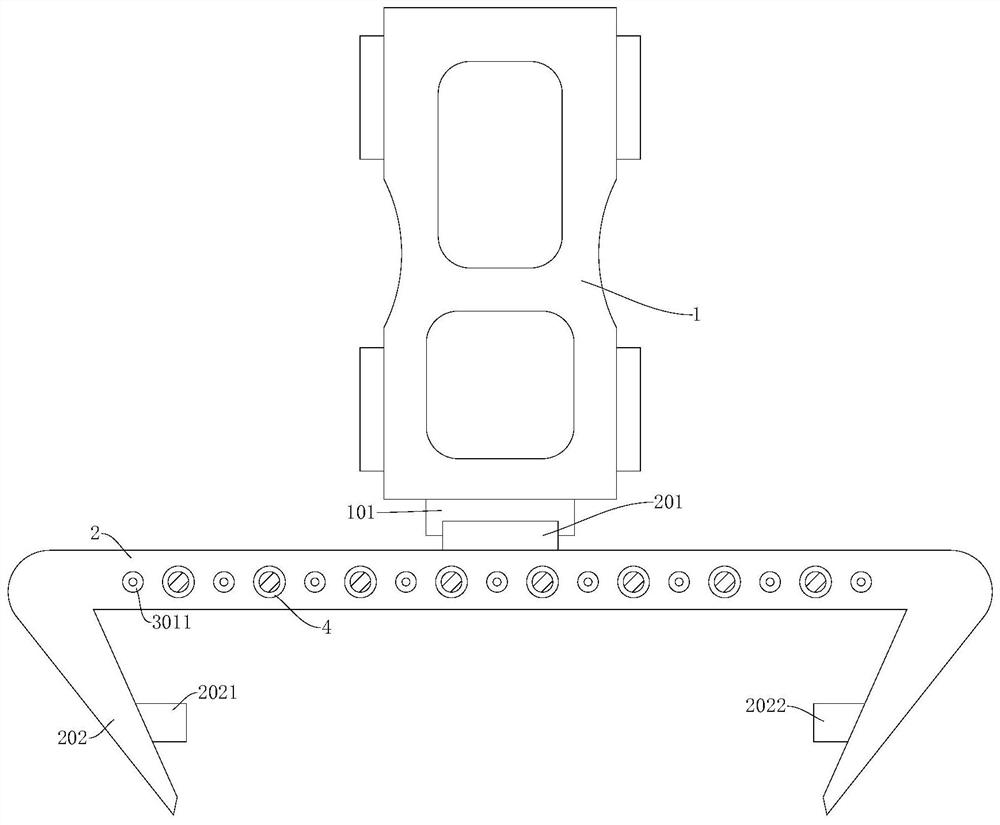

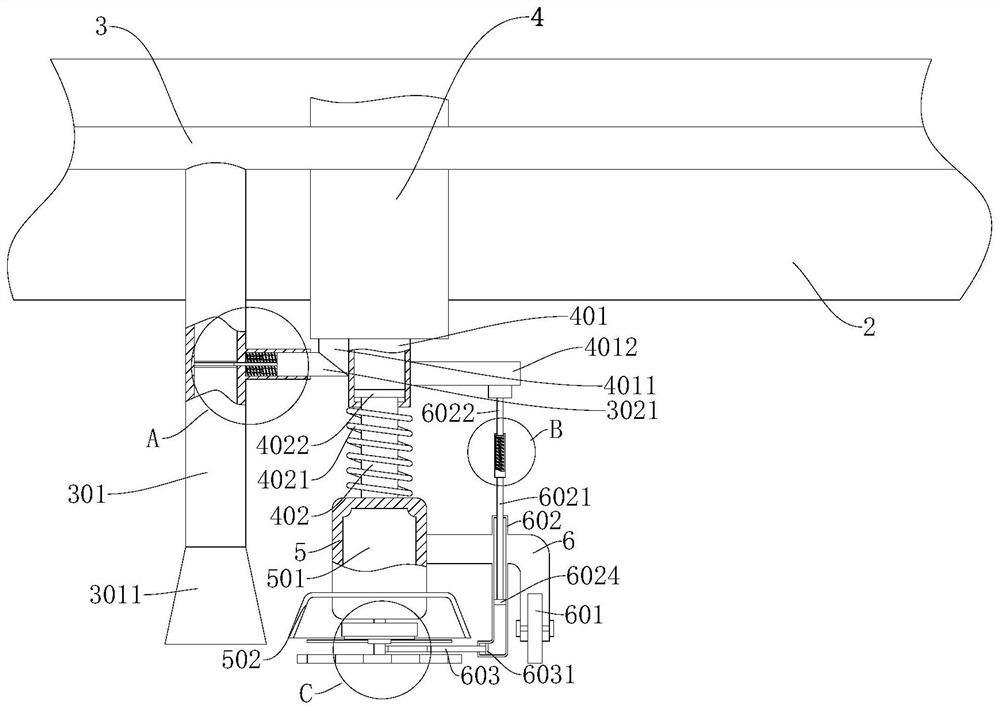

[0054] refer to Figure 1-6 , a large-scale intelligent spraying device, including a tractor 1 and an operating arm 2 slidably connected to the tractor 1, the operating arm 2 is fixedly connected with a conveying pipe 3, and an electric telescopic rod 4, and the conveying pipe 3 is fixedly connected There is a spraying pipe 301, the bottom of the spraying pipe 301 is fixedly connected with a spraying head 3011, the electric telescopic rod 4 is slidably connected with an electric sliding rod 401, and the electric sliding rod 401 is provided with a bump 4011, and the spraying pipe 301 is fixedly connected There is an installation cylinder 302, and a wedge 3021 is slidably connected in the installation cylinder 302, and the wedge 3021 fits with the protrusion 4011. A blocking plate 303 and a straight telescopic rod 3022 are fixedly connected to the wedge 3021, and the blocking plate 303 is slidably connected to the On the pipe 301, the spraying pipe 301 is fixedly connected with ...

Embodiment 2

[0057] refer to Figure 1-6 , is basically the same as in Embodiment 1, furthermore, the first piston plate 6031 is fixedly connected with the first piston rod 603, the cutting knife 6032 is fixedly connected with the first piston rod 603, and the second piston rod 6021 is fixedly connected with a The hollow column 6026, the connecting column 6022 is fixedly connected with the first baffle plate 6023, the first baffle plate 6023 is slidably connected in the hollow column 6026, the third spring 6025 is placed in the hollow column 6026, the two ends of the third spring 6025 are respectively connected with The hollow column 6026 and the first baffle 6023 offset, the first baffle 6023 and the hollow column 6026 offset, the electric slide bar 401 is fixedly connected with the installation frame 4012, the connecting column 6022 is fixedly connected with the installation frame 4012, and the round rod 402 is fixed A second baffle 4022 is connected, and the second baffle 4022 is slidab...

Embodiment 3

[0060] refer to Figure 1-6 , is basically the same as Embodiment 1, furthermore, the tractor 1 is fixedly connected with the installation block 101, the working arm 2 is fixedly connected with the slider 201, and the installation block 101 is provided with a chute that cooperates with the slider 201, The mounting block 101 is fixedly connected with a second motor 1011, the output end of the second motor 1011 is fixedly connected with a threaded rod 1012, the threaded rod 1012 is threaded on the slider 201, and the mounting block 101 is fixedly connected with a bracket 1013, the second motor 1011 is fixedly connected to the support 1013.

[0061] When the second motor 1011 works, the threaded rod 1012 will rotate, and when the threaded rod 1012 rotates forward, the slider 201 threaded on the threaded rod 1012 will slide upwards in the mounting block 101, so that the operating arm 2 moves upwards, Otherwise, the working arm 2 descends.

[0062]Working principle: In the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com