Battery

A technology for batteries and battery cells, applied in secondary batteries, circuits, battery pack components, etc., can solve problems such as high stress, no longer guaranteeing battery cell cooling, failure, etc., to achieve improved life expectancy and less risk of failure effect of stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

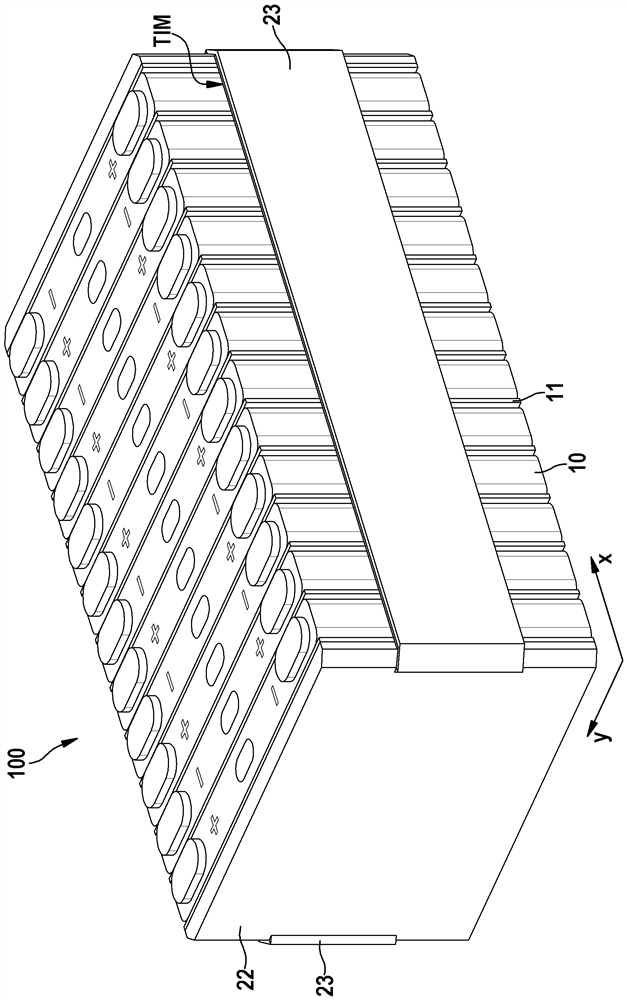

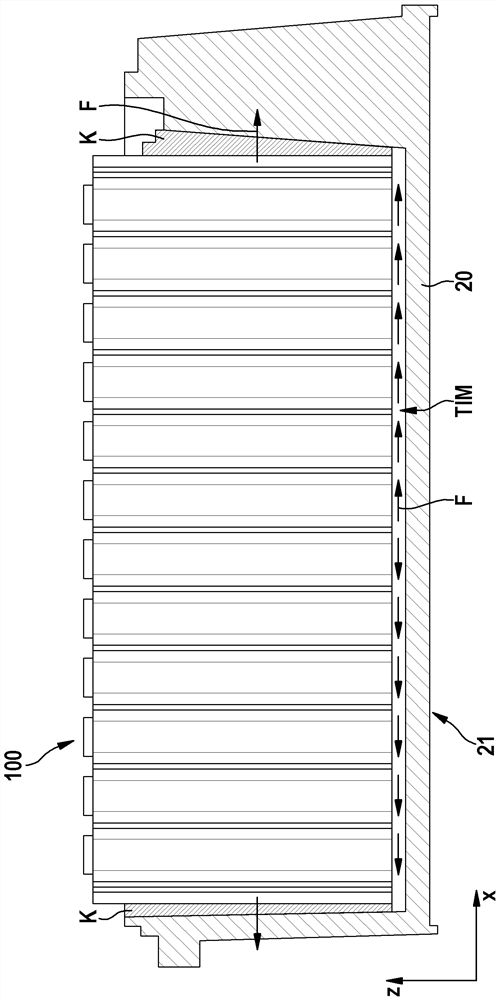

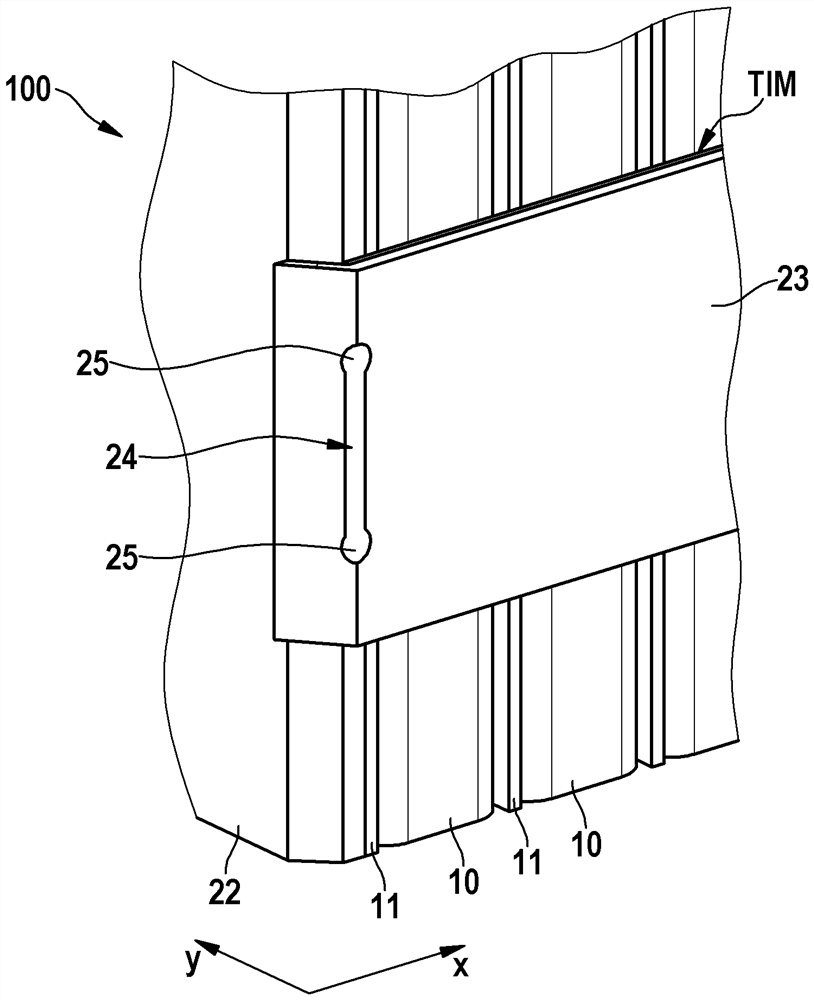

[0027] Figure 1 to Figure 4Shown is a battery 100, in particular a lithium-ion battery, which has a plurality of battery cells 10 which are interconnected to form a cell group (see figure 1 with figure 2 ) and is housed in housing 20 (see image 3 with Figure 4 ). according to image 3 , the battery cell 10 is bonded to the bottom 21 of the cell housing 20 by means of a thermally conductive adhesive TIM. as from figure 1 with figure 2 As can be seen, a plurality of spacer elements 11 are provided, one spacer element 11 being arranged in each case between two adjacent battery cells 10 . Alternatively, a spacer element 11 can also be arranged between the end-side battery cells 10 and the two end plates 22 .

[0028] The end plate 22 delimits the cell stack at the end side. The end plates 22 are connected by at least one tensioning strap 23 and in particular are tensioned against one another, so that the battery cells 10 are likewise tensioned between the end plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com