An air conditioning mechanism for building floors

A technology for air conditioning and buildings, applied in air humidification systems, applications, mechanical equipment, etc., can solve problems such as waste of resources, long-term use of power equipment, and easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

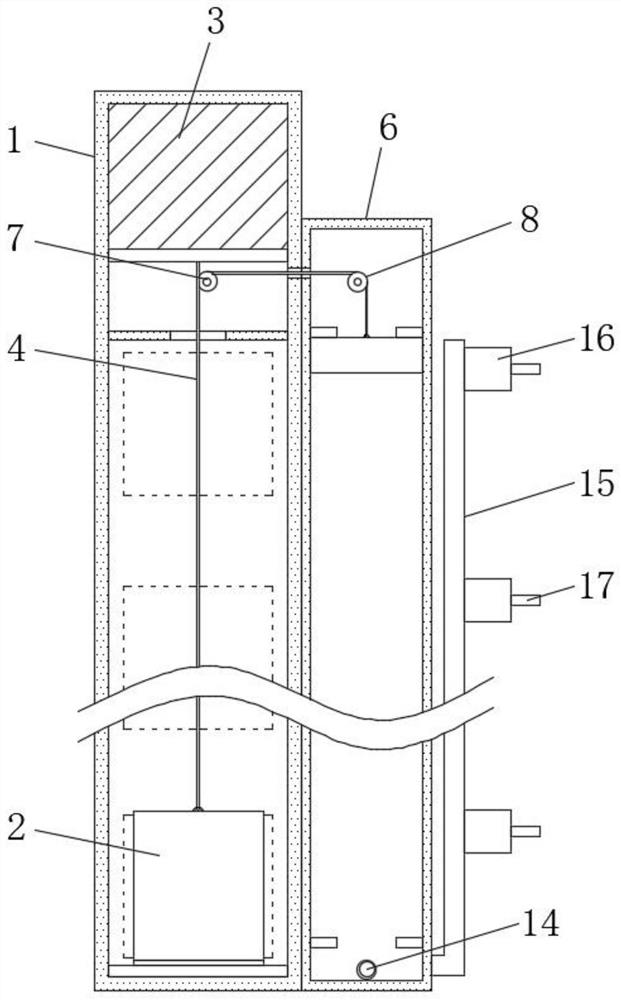

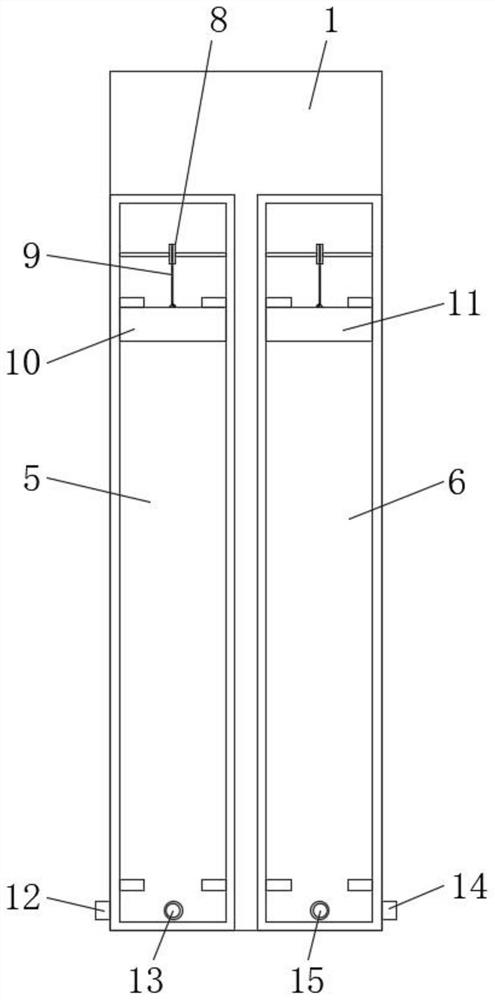

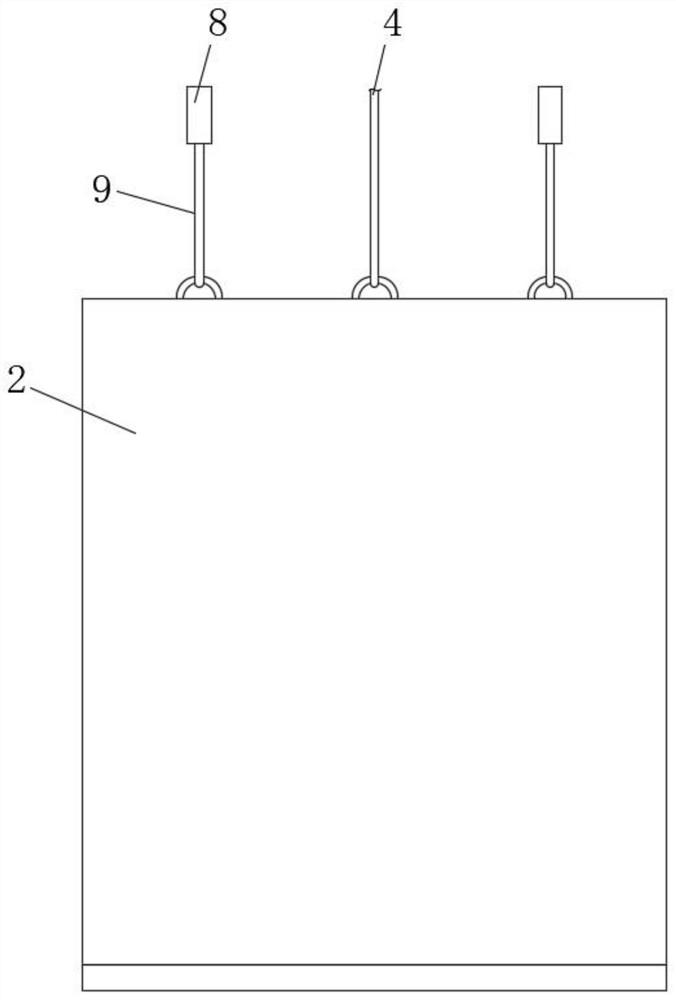

[0027]An air conditioning mechanism for building floors, the air conditioning mechanism is located on one side of the elevator shaft 1, the interior of the elevator shaft 1 is provided with a car 2 and a machine room 3, and the interior of the machine room 3 is provided with a traction machine, and the traction The machine is fixedly connected to the top of the car 2 through a rope 4. The air conditioning mechanism includes a first chamber 5 and a second chamber 6 located on one side of the elevator shaft 1. Roller 7, and the number of the first roller 7 is two, the inner top of the first chamber 5 and the second chamber 6 are all rotatably connected with the second roller 8, the inside of the first chamber 5 is located below the second roller 8 A first counterweight piston 10 is provided, and the outer peripheral wall of the first counterweight piston 10 is in close contact with the inner peripheral wall of the first chamber 5, and a second counterweight is arranged inside the...

Embodiment 2

[0035] Please focus on Figure 6 and 7 , The difference between this embodiment and Embodiment 1 is that: the top of the first chamber 5 is provided with a water pipe 23 penetrating to the inside of the first chamber 5, and the inside of the water pipe 23 is fixedly connected with a fixing plate 25, and the fixing plate 25 The bottom of the spring 26 is fixedly connected with a spring 26, and the bottom of the spring 26 is fixedly connected with a gasket 27. The inner wall of the water pipe 23 is located below the fixed plate 25 and is fixedly connected with a mounting plate 28, and the middle position of the mounting plate 28 is provided with a through hole 29. The top of a counterweight piston 10 is located at the rear end of the connecting rope 9 and is provided with a pipeline 24. The bottom of the first counterweight piston 10 is provided with an atomizing nozzle 33, and the top of the outside of the pipeline 24 is provided with a water inlet 31. The first counterweight p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com