Super lubricating composite film and preparation method thereof

A composite film and super-lubricating technology, applied in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of poor mechanical properties such as gel mechanical strength, unstable and limited lubricating performance of super-lubricating film, and achieve good lubrication Good lubricity and lubrication stability, good lubricity and lubrication stability, and high load pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the super-lubricating composite film provided by the present invention comprises: MoS 2 The nanosheets were uniformly dispersed in ethanol to obtain MoS 2 nanosheet dispersion; the PDMS prepolymer was dissolved in chloroform to obtain a PDMS prepolymer solution; the MoS 2 The nanosheet dispersion and the PDMS prepolymer solution are mixed evenly to obtain a mixed solution; after the mixed solution is dried, the PDMS prepolymer in it is polymerized to form polydimethylsiloxane to obtain a film matrix; lubricated The agent impregnates the film substrate to obtain a super lubricating composite film. The preparation process can prepare a super-lubricating composite film with good lubricity, lubrication stability and mechanical properties, and has the advantages of simple process, high efficiency and the like.

[0037] Optionally, MoS 2 In nanosheet dispersion, MoS 2 The concentration of nanosheets can be 1±0.5mg / mL; in the PDMS prepolymer solut...

Embodiment 1

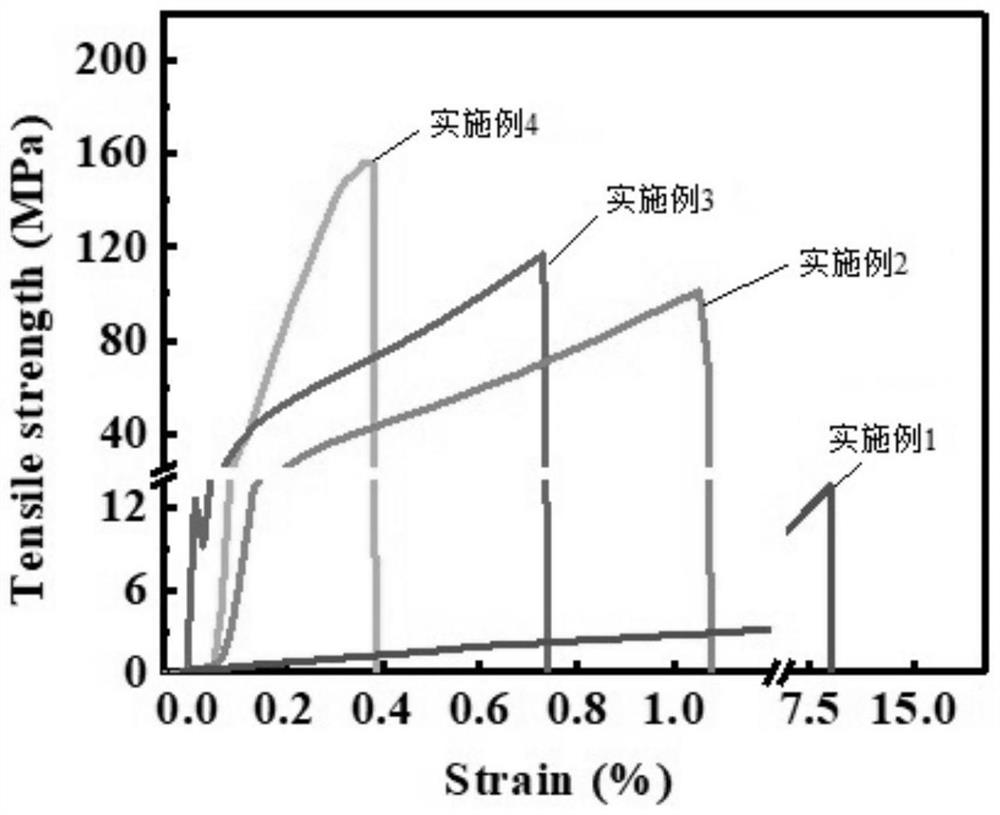

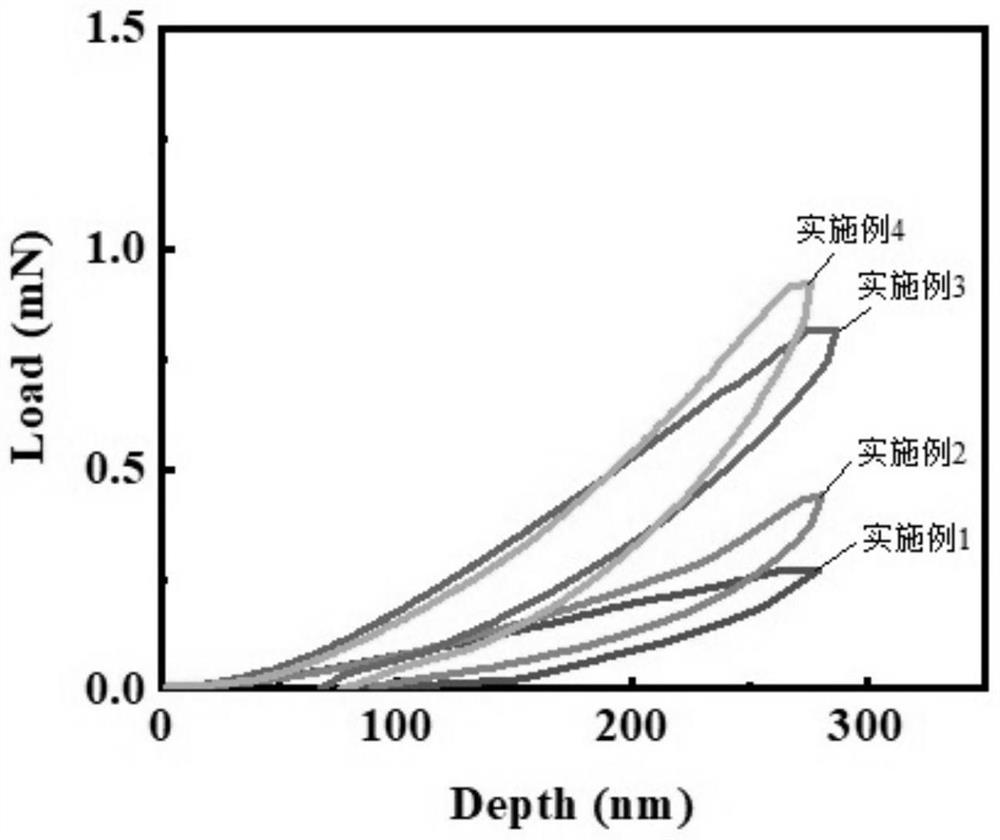

[0049] Take 2mL MoS 2 Nanosheet dispersion and 16mL PDMS prepolymer solution were mixed and stirred for 12 hours to obtain a uniform mixture. The mixture was placed in an oven and dried slowly at about 45°C for 48 hours. ℃ polymerization reaction for 2 hours, so that the PDMS prepolymer is polymerized into PDMS gel, and the membrane matrix is obtained; among them, MoS 2 The mass ratio of nanosheets to PDMS gel is 20:80 (i.e. MoS 2 The mass content of nanosheet is 20%), and the thickness of film matrix is 5 μm; Cutting length is the film matrix of 30mm, after testing, its tensile strength is 13.6MPa (see figure 2 ), the load pressure is 0.27mN (see image 3 ), the number of bending times for critical fracture is 1426 (see Figure 4 );

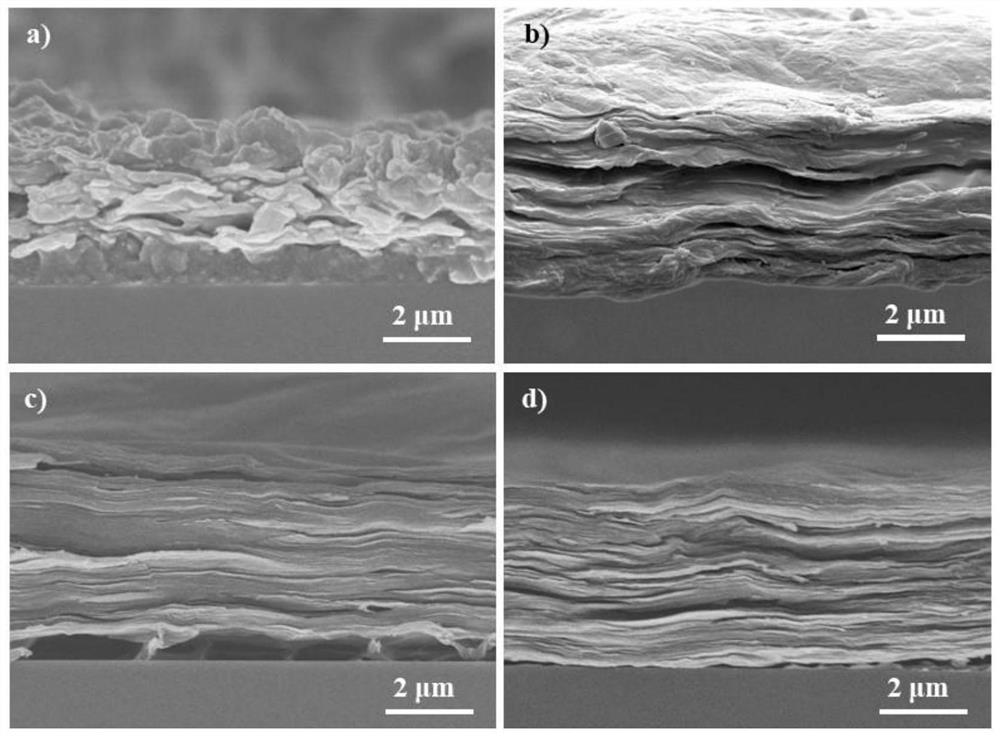

[0050] Soak the film matrix in silicone oil with a viscosity of 5cSt for 10 minutes, then take it out and drain the excess silicone oil to obtain a super lubricating composite film (see figure 1 a)) of.

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that MoS 2 The nanosheet dispersion is 4mL, and the PDMS prepolymer solution is 12mL; in the film matrix, MoS 2 The mass ratio of nanosheets to PDMS gel is 40:60; after testing, the tensile strength of the membrane matrix is 101MPa (see figure 2 ), the load pressure is 0.5mN (see image 3 ), the number of bending times for critical fracture is 2329 (see Figure 4 ); the SEM image of the super-lubricating composite film is shown in figure 1 b). All the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com