Single-matrix double-band white light emitting material and preparation method and application thereof

An emissive material and single-matrix technology, which is applied in the direction of luminescent materials, amino compound preparation, chemical instruments and methods, etc., can solve the problems of complex preparation process, difficult operation, high price, etc., and achieve simple preparation process, good repeatability, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

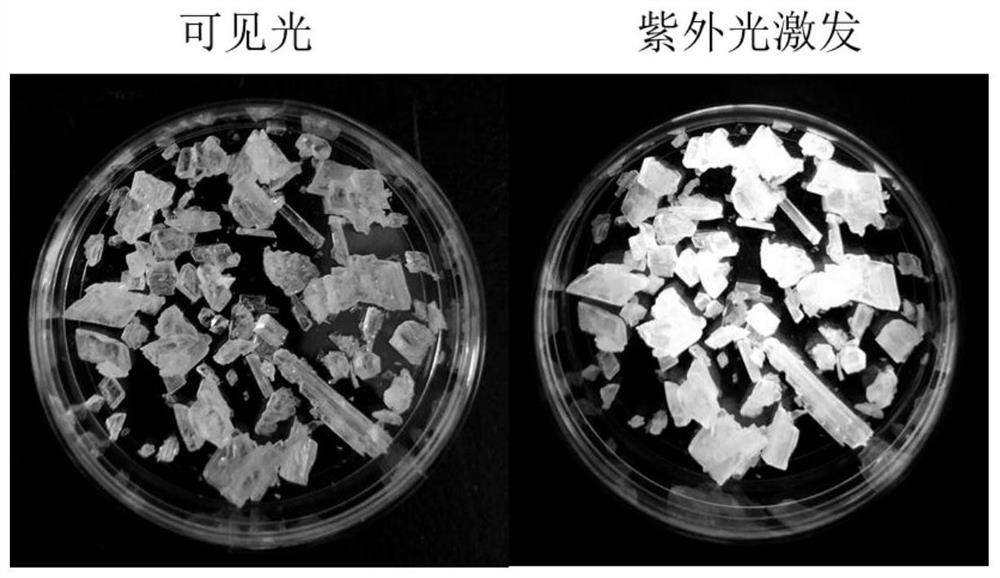

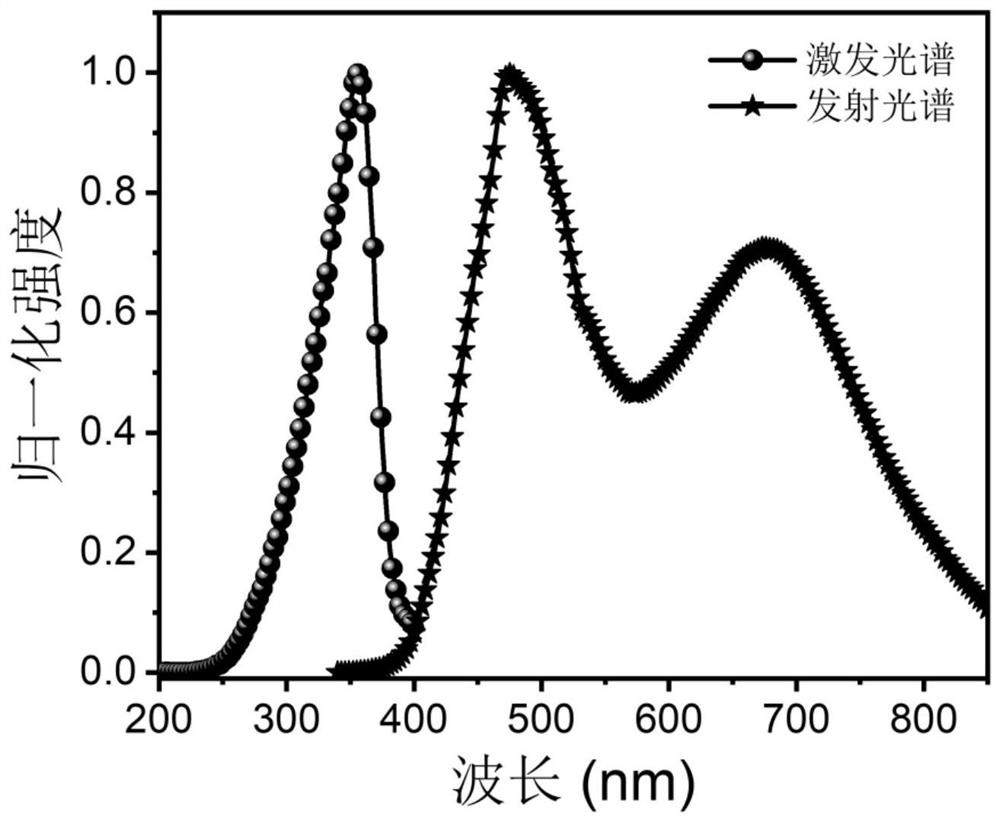

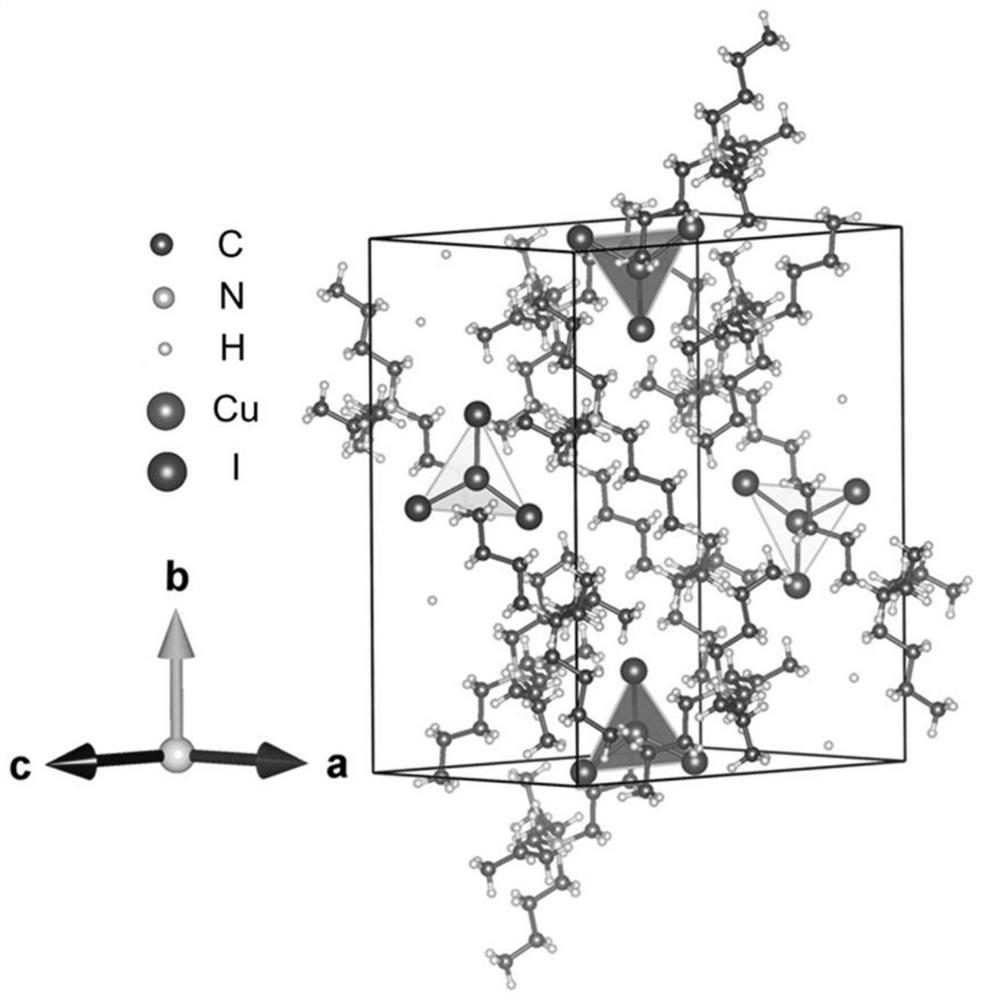

Examples

Embodiment 1

[0031] The preparation method of the white light single crystal in this embodiment, the specific preparation steps are as follows:

[0032] (1) Add 1mmol C 16 h 36 NI (CAS 311-28-4, purchased from Aladdin Chemical Reagent Network) and 1 mmol CuI were weighed and mixed in a glass bottle, and then 500 μL of organic solvent DMF and 100 μL of H 3 PO 2 , the above mixture was ultrasonically dissolved for 10min to obtain a clear precursor solution (the reason why this step uses H 3 PO 2 , is to suppress the monovalent copper ion Cu + Oxidation; In addition, H 3 PO 2 The dosage can be flexibly adjusted according to the actual situation, for example, H 3 PO 2 The volume ratio with the organic solvent may preferably be 1:5 to 1:30);

[0033] (2) Filter the reaction precursor solution obtained in the step (1) into a glass bottle with a filter head of 0.22 μm, and place the glass bottle statically in a fume hood;

[0034] (3) The filtered precursor solution obtained in the step...

Embodiment 2

[0037] The preparation method of the white light single crystal in this embodiment, the specific preparation steps are as follows:

[0038] (1) Add 1mmol C 16 h 36 NI and 1mmol CuI were weighed and mixed in a glass bottle, and then the organic solvent 2.9mL DMF and 100μL H 3 PO 2 , the above mixture was ultrasonically dissolved for 10 minutes to obtain a clear precursor solution;

[0039] (2) Filter the reaction precursor solution obtained in the step (1) into a glass bottle with a filter head of 0.22 μm, and place the glass bottle statically in a fume hood;

[0040] (3) The filtered precursor solution obtained in the step (2) is left to stand for 3 days in a fume hood, and single crystals with single matrix and double band white light emission will be precipitated and grown;

[0041] (4) Rinse the single-matrix double-band white light emission single crystal obtained in step (3) with ethanol, and dry naturally to obtain a clean single-matrix double-band white light emissi...

Embodiment 3

[0044] The preparation method of the white light single crystal in this embodiment, the specific preparation steps are as follows:

[0045] (1) Add 1mmol C 16 h 36 NI and 1 mmol CuI were weighed and mixed in a glass bottle, and then 500 μL of organic solvent DMSO and 100 μL of H were injected into it. 3 PO 2 , the above mixture was ultrasonically dissolved for 10 minutes to obtain a clear precursor solution;

[0046] (2) Filter the reaction precursor solution obtained in the step (1) into a glass bottle with a filter head of 0.22 μm, and place the glass bottle statically in a fume hood;

[0047] (3) The filtered precursor solution obtained in the step (2) is left to stand in a fume hood for 1 day, and a single crystal with a single matrix and double band white light emission will be precipitated and grown;

[0048] (4) Rinse the single-matrix double-band white light emission single crystal obtained in step (3) with ethanol, and dry naturally to obtain a clean single-matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com