Method for determining spreading amount of abrasion material for improving early-stage anti-skid performance of SMA-13 pavement

A technology for determining the method and the amount of spreading, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of insufficient guarantee rate of anti-skid improvement, achieve scientific and reasonable average particle size, improve certainty, The effect of improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

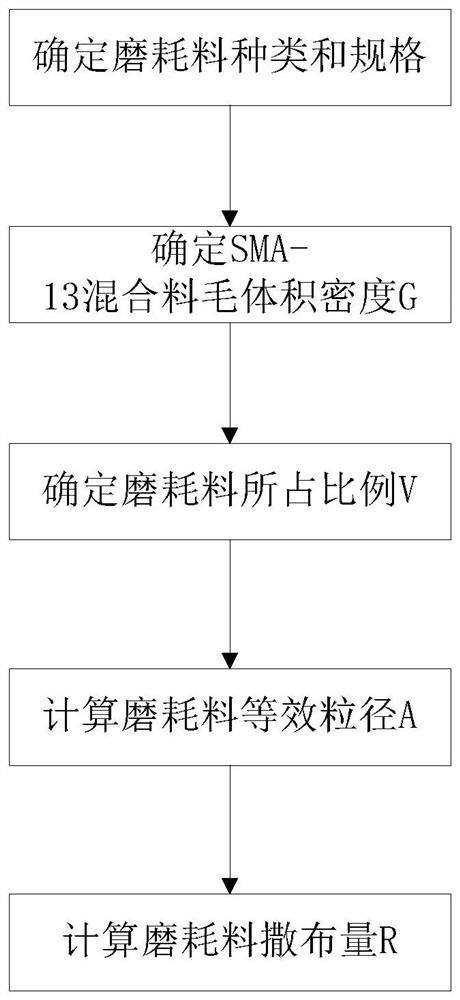

[0034] as attached figure 1 As shown, taking SMA-13 asphalt pavement as an example:

[0035] S1. Determine the type and specification of abrasive materials:

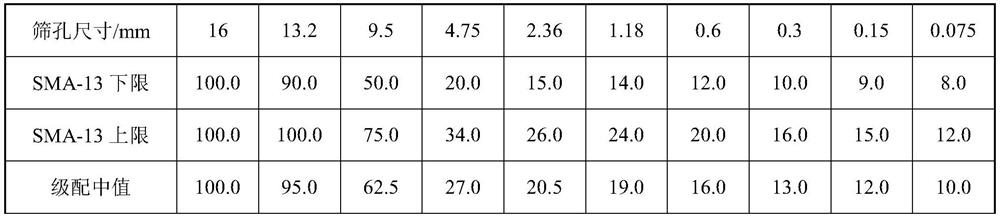

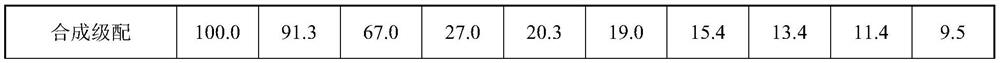

[0036] According to the characteristics of the discontinuous 2.36-4.75mm of the SMA-13 mixture, the broken steel slag is selected as the abrasive material (embedded extrusion material), and the passing rate requirements of the 2.36-4.75mm abrasive material are shown in Table 1:

[0037] Table 1 2.36-4.75mm wear material passing rate requirement table

[0038] Sieve hole / mm Passing rate / % 4.75 90-100 2.36 0-15

[0039] According to the requirements of Table 1, determine the specific specifications of abrasive materials as shown in Table 2:

[0040] Table 2 Abrasive material passing rate table

[0041] Sieve hole / mm Passing rate / % 4.75 91.2 2.36 8.5

[0042] S2. Determine the gross bulk density G of the SMA-13 mixture:

[0043] The measured value of the bulk d...

Embodiment 2

[0054] Embodiment 2: The asphalt road section is treated according to the amount of abrasive material spread calculated in Embodiment 1, specifically as follows:

[0055] (1), sieve 200kg of steel slag abrasive material shown in Table 2, heat it to 155°C, weigh 0.3% of the abrasive material quality 70# road petroleum asphalt for pre-mixing, and cool for standby;

[0056] (2) After the SMA-13 mixture is paved by the paver, determine the treatment area, with 1m 2 Divide the grid as a unit, and calculate the abrasive spreading amount of 0.82kg / m in Example 1 2 Spread the abrasive material evenly;

[0057] (3) Rolling is completed according to the conventional SMA-13 rolling process;

[0058] (4), anti-skid performance test is carried out on the untreated road section and the treated road section, and the detection index includes BPN20, TD, DF60, SFC60, and the specific results are shown in Table 4:

[0059] Table 4 Anti-skid performance comparison test results table

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com