Deoiling and filtering device for petroleum wastewater

A technology for oil filtration and waste water, which is used in grease/oily substance/float removal devices, filtration treatment, water/sewage treatment, etc. It can solve the problems of clogging the oil-water separation filter and inconvenient cleaning of solid impurities, and achieve convenient removal. , the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

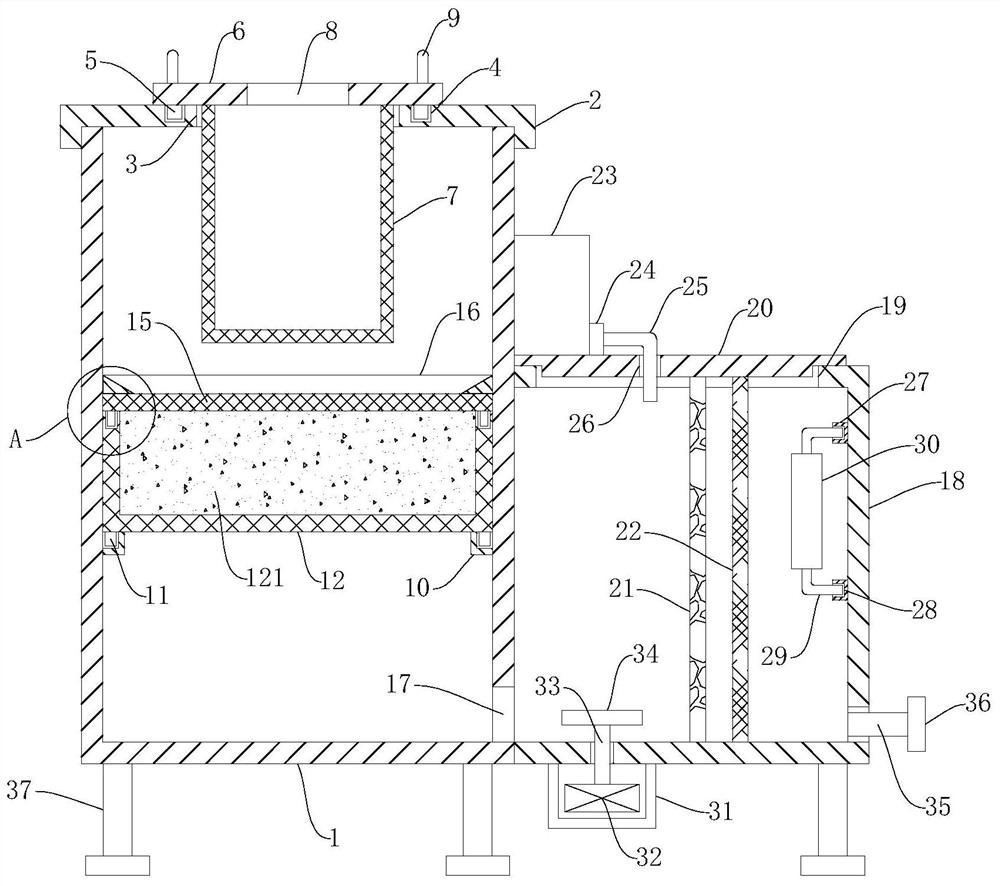

[0026] refer to Figure 1-5 , a petroleum wastewater degreasing and filtering device, comprising a box body 1, the four corners of the bottom end of the box body 1 are welded with support legs 37, the top of the box cover 2 is provided with a first through hole 3, and the top of the box cover 2 is located in the first through hole The outside of the hole 3 is uniformly provided with a first card slot 4, the first card slot 4 is clamped with a first card block 5, the top of the first card block 5 is welded with a fixed plate 6, and the bottom end of the fixed plate 6 is connected to the box cover. 2 are in contact with each other, the bottom of the fixed plate 6 is welded with a solid impurity filter barrel 7, the solid impurity filter barrel 7 is matched with the first through hole 3, the top middle of the fixed plate 6 is provided with a water inlet 8, and the fixed plate The outer top of 6 is symmetrically welded with a handle 9, the box body 1, the case cover 2, the first t...

Embodiment 2

[0031] refer to Figure 1-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the dosing mechanism includes a medicine storage box 23 placed on the top of the sealing cover plate 20, and a pump body 24 is installed at the bottom end of one side of the medicine storage box 23 , the outlet end of the pump body 24 is equipped with a connecting pipe 25, one end of the connecting pipe 25 runs through the sealing cover 20, and extends to the inside of the fixed box 18, the top of the sealing cover 20 is provided with a fourth Through hole 26, medicine storage box 23, pump body 24, connecting pipe 25 and the fourth through hole 26 are arranged in cooperation, can conveniently add the wastewater treatment liquid into the fixed box 18, when in use, start the pump body 24, The liquid medicine stored in the medicine storage box 23 is pumped into the connecting pipe 25 , and then flows into the fixed box 18 through the connecting pipe 25 ...

Embodiment 3

[0033] refer to Figure 1-5 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that the stirring mechanism includes a fixed frame 31 welded on one side of the bottom end of the fixed box 18, and a motor 32 is installed on the inner surface of the fixed frame 31, and the motor 32 passes through The bearing is connected with a rotating shaft 33, and one end of the rotating shaft 33 extends to the inside of the fixed box 18, and the extended end is equipped with a stirring wheel 34, and the cooperating arrangement between the fixed mount 31, the motor 32, the rotating shaft 33 and the stirring wheel 34 can facilitate When mixing the liquid medicine and the separated waste water, when in use, start the motor 32 to drive the rotating shaft 33 to rotate, and the rotating shaft 33 drives the stirring wheel 34 to rotate, so that the stirring wheel 34 mixes the waste water and the liquid medicine in the fixed box 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com