Automatic polishing equipment for high-toughness plastic automobile steel

An automatic polishing and automotive steel technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of reduced work efficiency and increased labor costs, and achieve high work efficiency, good automation effect, Provides a time-sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

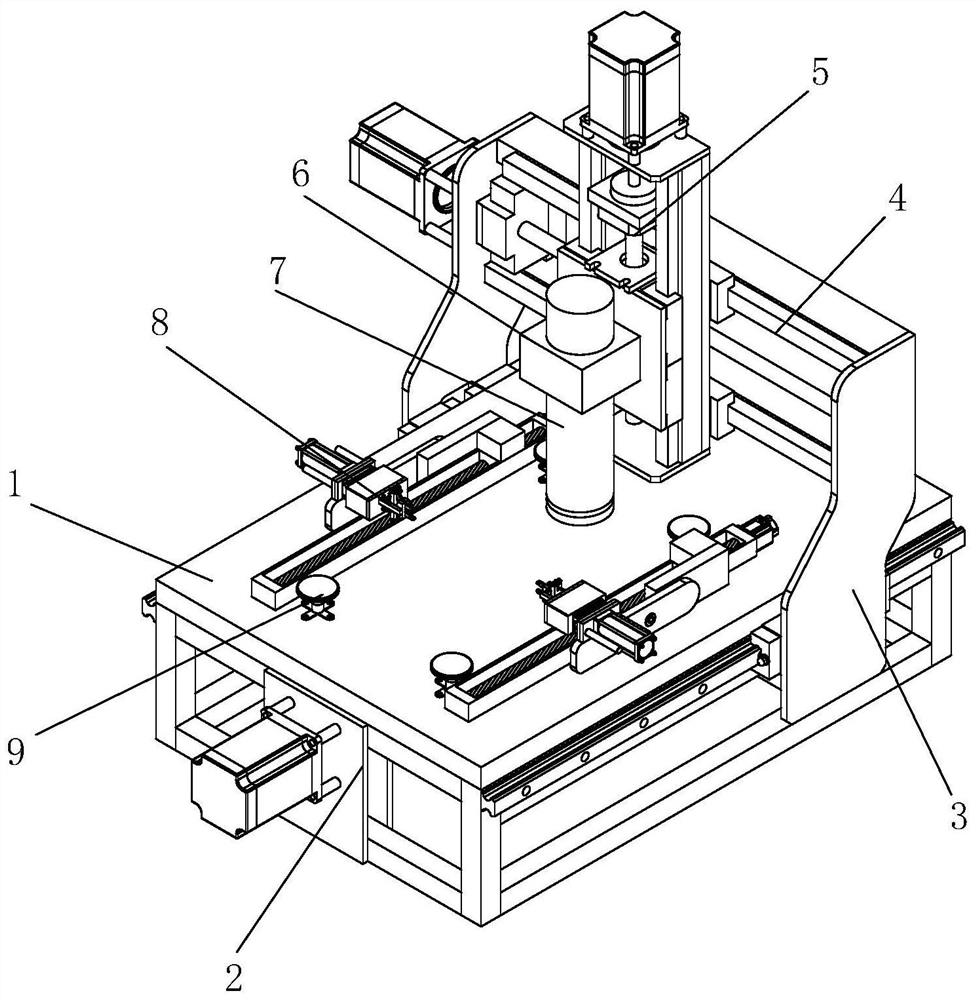

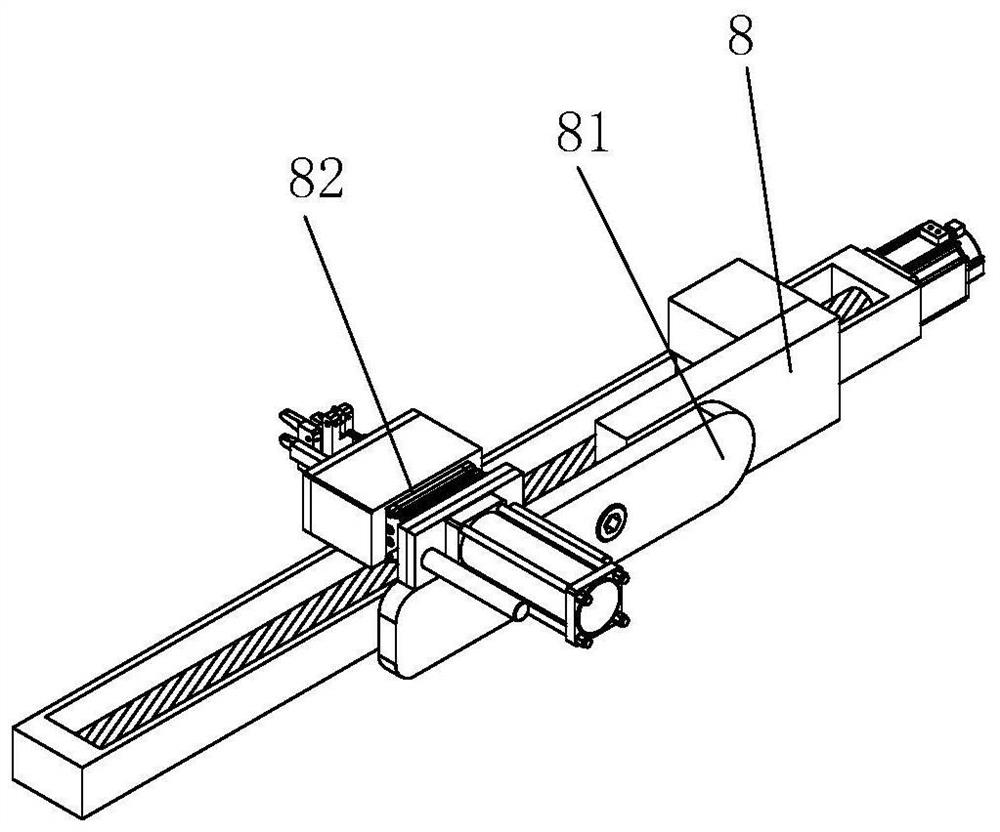

[0034] see figure 1 , the present invention provides a high-toughness and plasticity automatic polishing equipment for automobile steel here, including a workbench 1, a Y-axis slide table 2 is installed in the middle of the workbench 1, and the two sides of the Y-axis slide table 2 are connected with the support arm 3 , the upper end of the support arm 3 is connected to the X-axis slide table 4, the front end of the X-axis slide table 4 is provided with a Z-axis slide table 5, the front end of the Z-axis slide table 5 is installed with a fixing member 6, and the inner middle of the fixing member 6 is provided with a polishing mechanism main body 7. It also includes auxiliary devices 8 arranged on the top ends of the workbench 1 for clamping and adjusting the polishing position of the automobile steel and four groups of support mechanisms 9 arranged on the top of the workbench 1 for supporting the automobile steel. The auxiliary devices 8 are provided There are two sets of auxi...

Embodiment 2

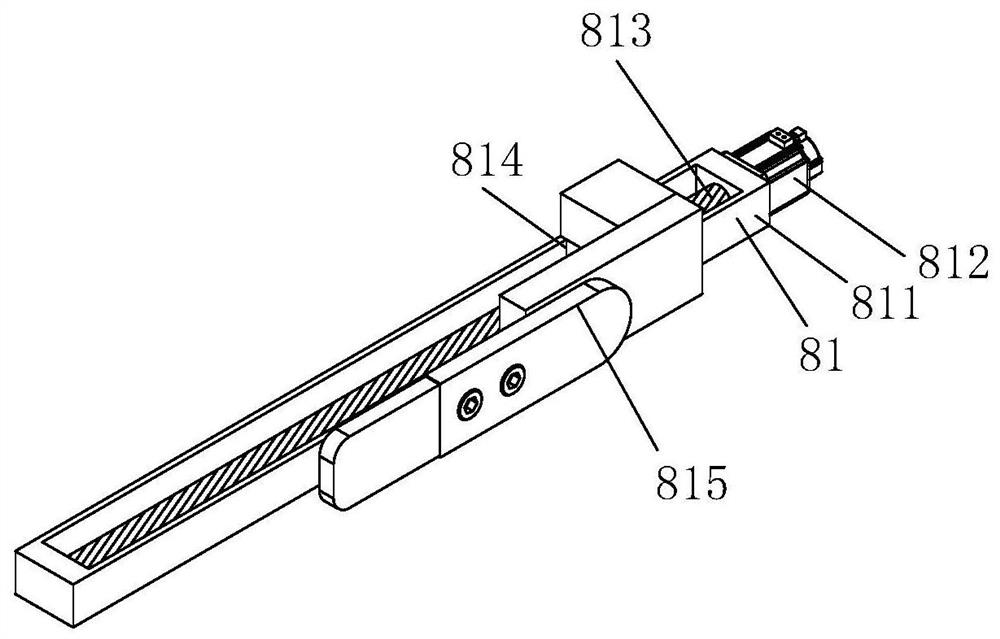

[0042] The present invention provides an automatic polishing equipment for high-toughness and plasticity automobile steel through improvement. The bottom surface of the motor box 8151 is smooth, and the bottom of the motor box 8151 is in contact with the top of the fixed frame 811, which is convenient for smooth sliding; The arc shape is convenient for rotation without being hindered; the locking piece 91 is in the shape of a cross, and the bottom of the locking piece 91 is attached to the top of the workbench 1, and is fixed by four sets of bolts, the connection is stable and the fixation is good; the lower end of the adjusting column 93 A screw is fixed, and the screw is screwed into the support column 92, which is convenient to rotate and realize height adjustment; the top of the tray 94 is bonded with a silica gel layer, which has good supporting effect, large friction and stability.

[0043] The present invention provides an automatic polishing equipment for high toughness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com