Cooling unit, method for manufacturing cooling unit, and structure

A technology of cooling unit and fine concave-convex structure, applied in cooling/ventilation/heating renovation, electrical components, electrical solid devices, etc., can solve the problems of refrigerant leakage, deformation of cooling unit, submerged circuit components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

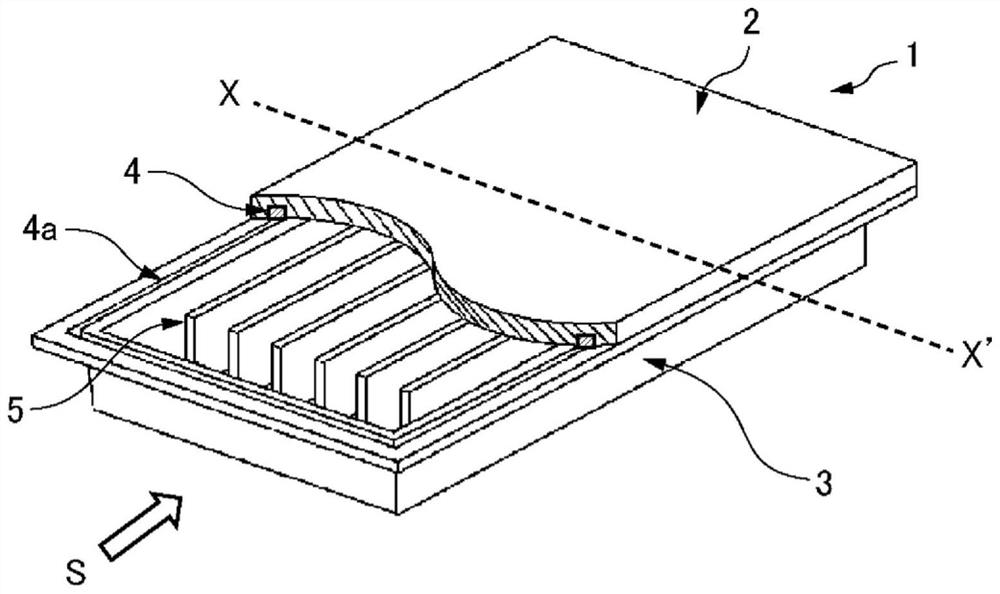

preparation example Construction

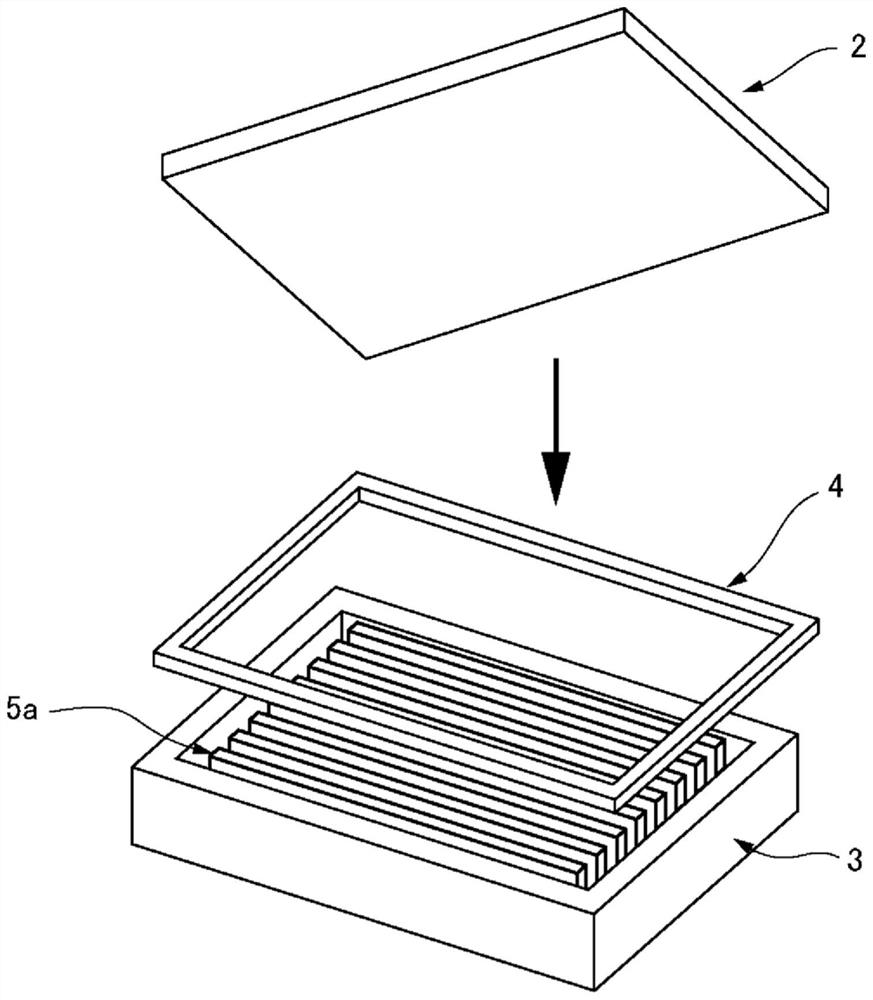

[0124] 1. Preparation of the resin platter 3

[0125] 2. Additional securing of the elastic pad 4

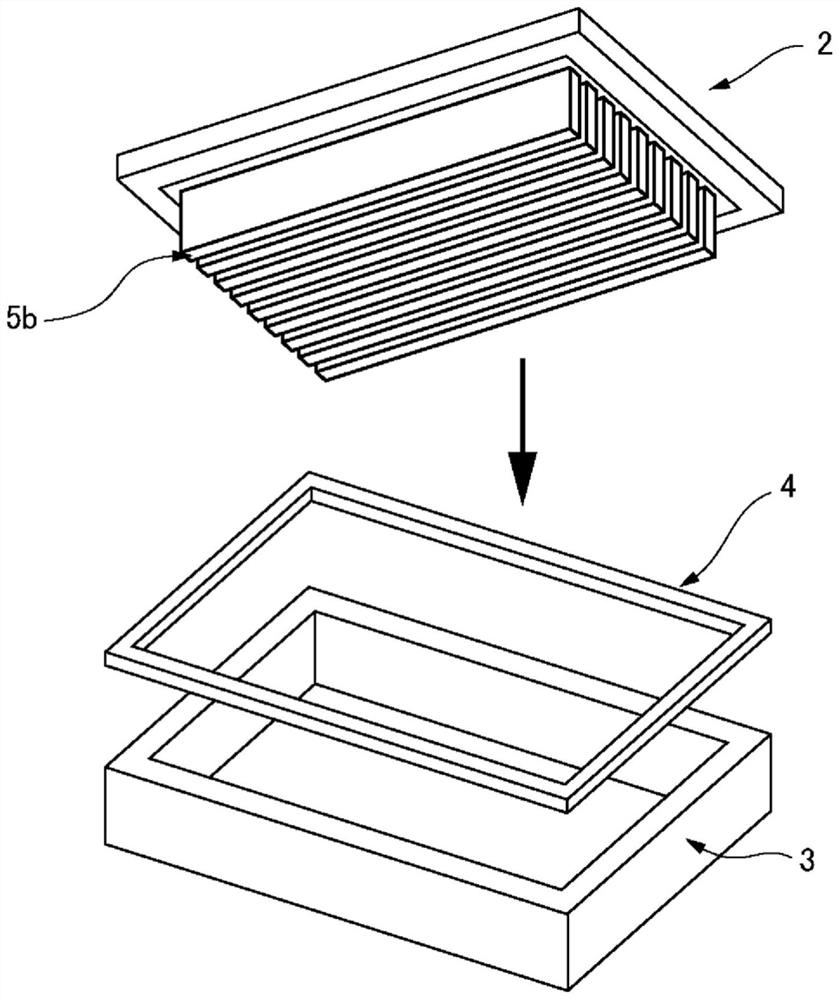

[0126] 3. Preparation of the metal plate 2 with the elastic gasket 4 bonded by injection or adhesive bonding

[0127] 4. Mechanical connection between the top surface of the side wall of the resin tray 3 and the metal plate 2 via a gasket

[0128] In the method A, a method (adhesive bonding) in which the metal plate 2 is bonded to a belt-shaped or ring-shaped elastic spacer 4 separately prepared by injection molding or other molding means through an adhesive agent and molded as a representative example is mentioned. . Method A preferably includes a step of applying an adhesive to the fine unevenness structure on the surface of the metal plate 2 by a known method.

[0129] In method B, the cooling unit 1 according to this embodiment is assembled by mechanically connecting the resin platter 3 prepared by the method described above to the metal plate 2 with the elastic gasket. ...

Embodiment 1

[0160] The die for the leak test was attached to J85AD110H manufactured by Nippon Steel Works, and the surface-roughened aluminum alloy plate M1 obtained by the method described above was set in the die. Next, in the mold, the above-mentioned resin composition A1 was injection-molded under the conditions of a cylinder temperature of 190°C, a mold temperature of 40°C, an injection speed of 25mm / sec, a dwell pressure of 80MPa, and a dwell time of 10 seconds. , and a composite structure formed of the surface-roughened aluminum alloy plate M1 and the bonding pad composed of the above-mentioned resin composition A1 was produced. Furthermore, a joint gasket made of the above-mentioned resin composition A1 formed in advance was mechanically connected to the above-mentioned surface-roughened aluminum alloy M1 by screws, thereby obtaining a test piece for a leak test. A cross-sectional photograph of the boundary between the bonding pad and the metal plate in the obtained test piece is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com