Gas meter

A gas meter and gas technology, applied in measuring devices, instruments, measuring flow/mass flow, etc., can solve the problems of low safety in use and low production efficiency of gas meters, and achieve high safety, good resistance to external force, and good sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] Specific embodiment 1 of the gas meter provided by the present invention. In this embodiment, the ultrasonic gas meter is taken as an example to introduce and illustrate the specific structure of the gas meter in the present invention. In other embodiments, the gas meter can also be other outlets. Structured gas meters, such as membrane gas meters.

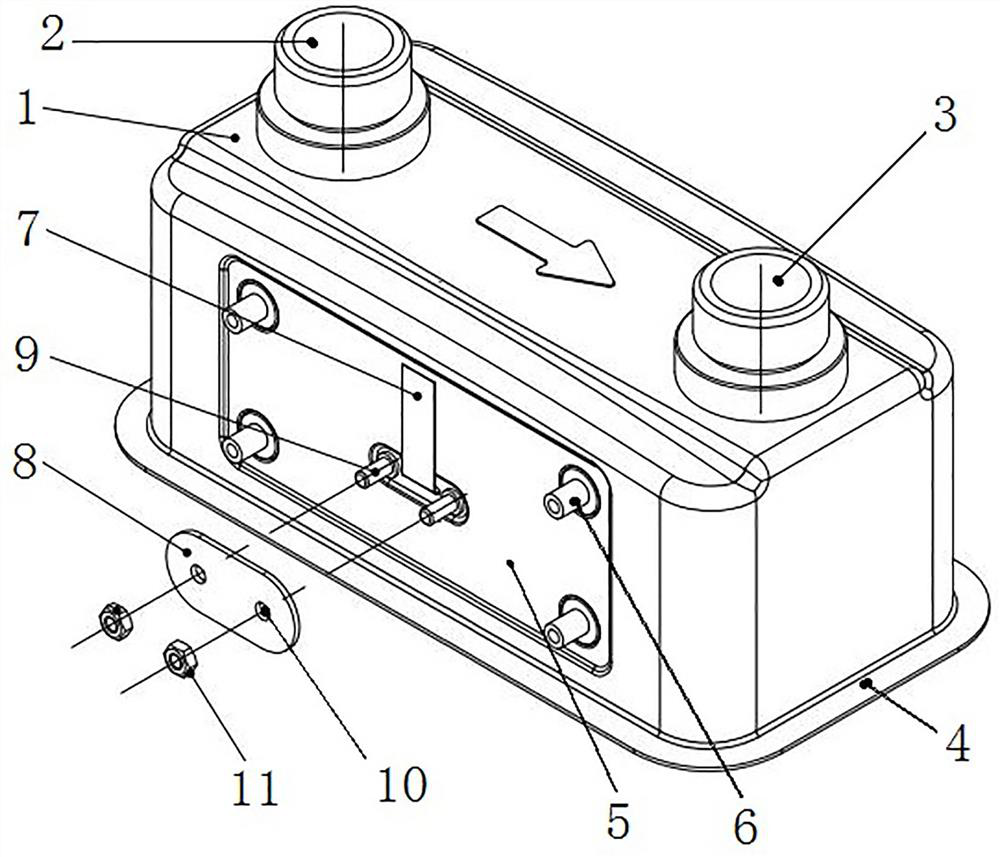

[0035] The gas meter has a casing. In this embodiment, the casing is an upper and lower split structure, including an upper casing 1 and a lower casing. The structure of the upper casing 1 is as follows: figure 1 As shown, the cross section of the upper shell 1 is rectangular, the top surface is provided with an air inlet port 2 and an air outlet port 3, the lower part is a shell mouth for docking with the lower shell, and there is a circle at the shell mouth for connecting with the lower shell. The valgus edge 4 that the body shell mouth place is turned over cooperates. The inner cavity of the casing is used to accommodat...

specific Embodiment 2

[0041] The specific embodiment 2 of the gas meter provided by the present invention differs from the embodiment 1 mainly in that in the embodiment 1, the sealant is applied to the opening of the wire hole to realize the sealing of the outlet structure. In this embodiment, A seal is set between the data transmission line and the inner wall of the wire hole, specifically, a rubber sealing ring is installed on the data transmission line to realize the sealing of the outlet structure. The size of the rubber sealing ring meets the requirements of the pressure plate. compression deformation. Of course, in other embodiments, a sealing ring can be placed on the cable hole or a sealing gasket can be placed in the groove, and the data transmission line can pass through the opening of the sealing ring or the sealing gasket.

specific Embodiment 3

[0042] The specific embodiment 3 of the gas meter provided by the present invention is mainly different from the embodiment 1 in that in the embodiment 1, the shell is a split structure up and down, and in this embodiment, the shell is a split structure in front and rear or left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com