Soil conditioner and nursery stock planting method adopting soil conditioner

A technology of soil improver and bentonite, which is applied in the fields of seedling planting and soil improver, which can solve the problems of unfavorable plant growth, lower oxygen concentration, and lower air permeability, and achieve high oxygenation efficiency, large oxygenation amount, and enhanced air permeability and the effect of water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

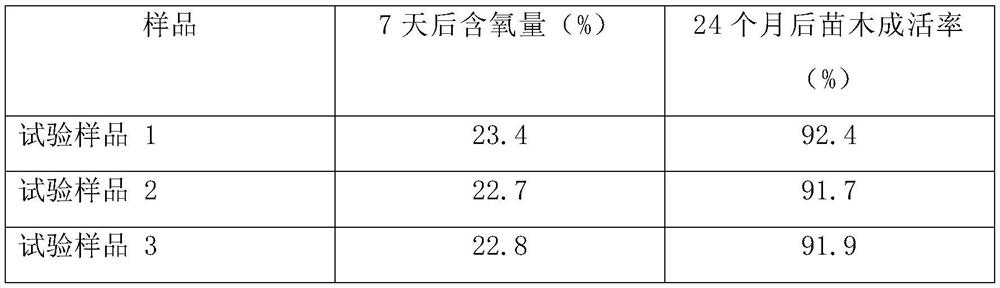

Examples

Embodiment 1

[0037] A soil conditioner, its components and their corresponding parts by weight are as shown in Table 1, and are prepared through the following steps: Step (1): Get raw material stalks, volcanic ash, bentonite, earthworm soil, Organic matter and linseed oil residue are ground into powder to obtain mixed powder;

[0038] Step (2): Mix the mixed powder obtained in step (1) in a high-speed mixer for 5 minutes at a stirring speed of 500 rpm, then add sillimanite and calcium mannitol in parts by weight, and continue mixing and stirring for 10 minutes. Minutes to get soil conditioner.

[0039] Note: The organic matter in the above steps is cow dung with a water content of 17.5wt%; the particle size of sillimanite is 7.5 μm.

Embodiment 2-4

[0041] A soil conditioner, the difference from Example 1 is that each component and its corresponding parts by weight are as shown in Table 1.

[0042] Each component and parts by weight thereof in table 1 embodiment 1-4

[0043] raw material Example 1 Example 2 Example 3 Example 4 straw 7 5 6.5 8 volcanic ash 14 15 12.5 10 Bentonite 44 40 45 50 earthworm soil 10 12 10 8 organic matter 4 3 4 5 silica pumice 5 9 6.5 4 Calcium Mannitol 2 1.5 2.5 3.5 Linseed oil residue 3 2 4.5 7

Embodiment 5

[0045] A soil conditioner, the difference from Example 1 is that the organic matter water content in the above steps is 15wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com