Environment-friendly cold-mixed recycled asphalt mixture and preparation method and application thereof

A technology of recycled asphalt and mixture, which is applied in the field of environmentally friendly cold-mix recycled asphalt mixture, which can solve the problems of low proportion, rutting, overpacking, reduction of mixture strength and Marshall stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

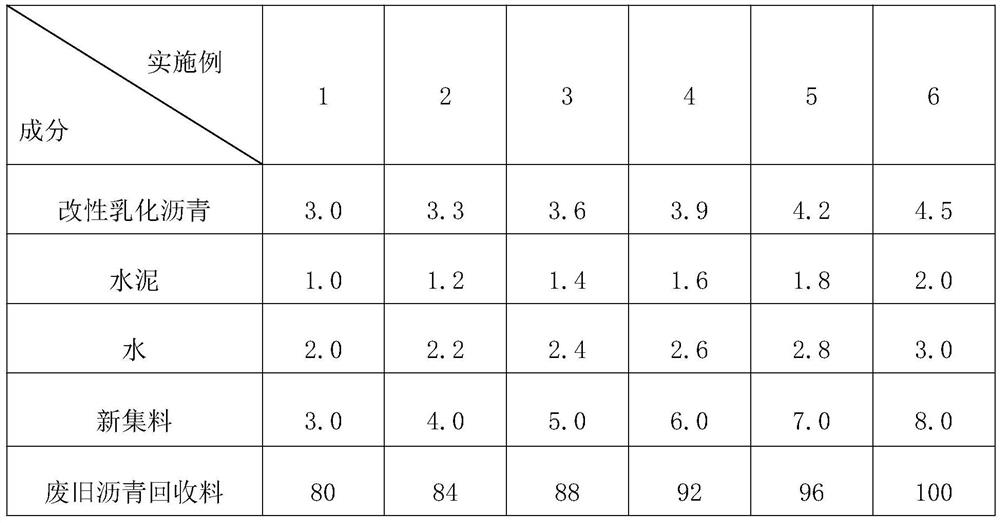

Examples

preparation example 1

[0071] A kind of modified emulsified asphalt, its preparation steps are as follows:

[0072] a. Put 10kg of waste construction pipes into a ball mill, grind and crush them, pass through a 100-mesh sieve, then add them to 50kg of asphalt, heat to a molten state at 230°C, and prepare a molten asphalt mixture, keep it warm for later use;

[0073] b. Stir and mix 3kg of SBS modifier, 1kg of emulsifier and 0.5kg of stabilizer according to the corresponding ratio at 800r / min for 10min, then heat to 60°C to prepare the modified solution for later use;

[0074] c. Add the modified liquid into the molten asphalt mixture according to the ratio, and stir at 2000r / min for 30 minutes to prepare the modified emulsified asphalt;

[0075] Construction waste pipes are composed of pipes made of PET, PVC, and PE in a weight ratio of 1:0.5:0.5;

[0076] The emulsifier is OS MS-1 emulsifier, purchased from Haian Petrochemical Plant in Jiangsu Province;

[0077] The stabilizer is SBS stabilizer, ...

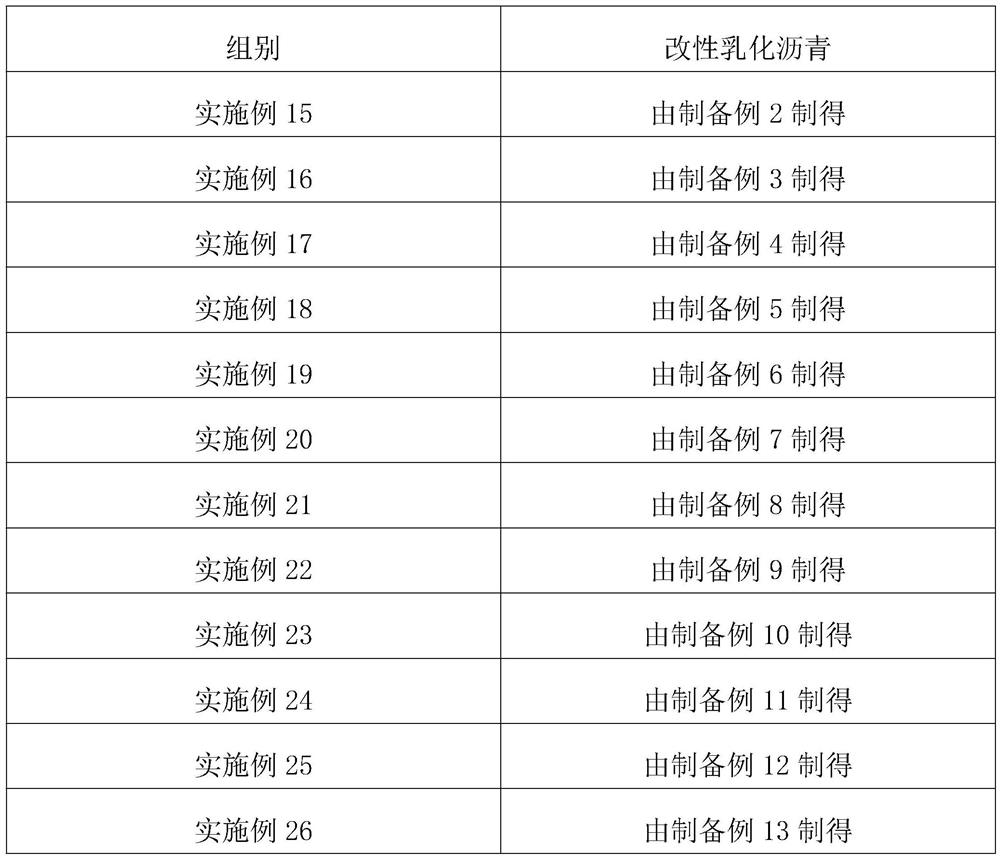

preparation example 2

[0079] A kind of modified emulsified asphalt, its preparation steps are as follows:

[0080] a. Put 12.5kg of discarded construction pipes into a ball mill, grind and crush them, pass through a 100-mesh sieve, then add them to 65kg of asphalt, heat to a molten state at 250°C, and prepare a molten asphalt mixture, keep it warm for later use;

[0081] b. Stir and mix 4kg of SBS modifier, 3kg of emulsifier and 1kg of stabilizer according to the corresponding ratio at 800r / min for 10min, then heat to 70°C to prepare the modified solution for later use;

[0082] c. Add the modified liquid into the molten asphalt mixture according to the ratio, and stir at 2000r / min for 30 minutes to prepare the modified emulsified asphalt;

[0083] Construction waste pipes are composed of pipes made of PET, PVC, and PE in a weight ratio of 1:0.5:0.5;

[0084] The emulsifier is OS MS-1 emulsifier, purchased from Haian Petrochemical Plant in Jiangsu Province;

[0085] The stabilizer is SBS stabiliz...

preparation example 3

[0087] A kind of modified emulsified asphalt, its preparation steps are as follows:

[0088] a. First, put 15kg of waste construction pipes into a ball mill, grind and crush them, pass through a 100-mesh sieve, then add them to 80kg of asphalt, heat to a molten state at 270°C, and prepare a molten asphalt mixture, keep it warm for later use;

[0089] b. Stir and mix 5kg of SBS modifier, 5kg of emulsifier and 1.5kg of stabilizer according to the corresponding ratio at 800r / min for 10min, then heat to 80°C to prepare the modified solution for later use;

[0090] c. Add the modified liquid into the molten asphalt mixture according to the ratio, and stir at 2000r / min for 30 minutes to prepare the modified emulsified asphalt;

[0091] Construction waste pipes are composed of pipes made of PET, PVC, and PE in a weight ratio of 1:0.5:0.5;

[0092] The emulsifier is OS MS-1 emulsifier, purchased from Haian Petrochemical Plant in Jiangsu Province;

[0093] The stabilizer is SBS stabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com