Automatic material loading and unloading equipment

A technology for automatic loading and unloading of materials, applied in loading/unloading, transportation and packaging, conveyors, etc., which can solve problems such as time-consuming and labor-intensive, low handling efficiency, and large volume of forklifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

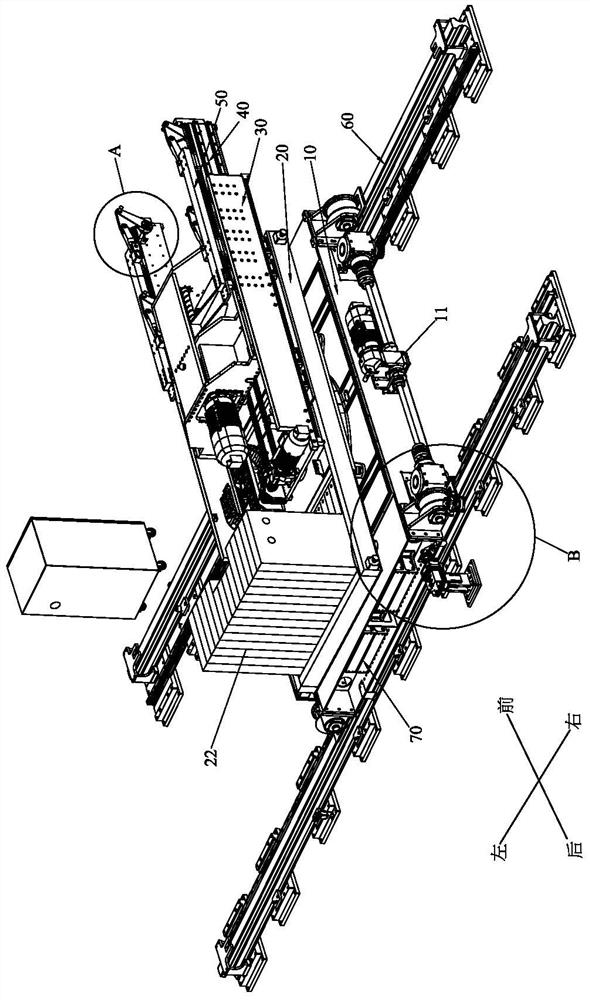

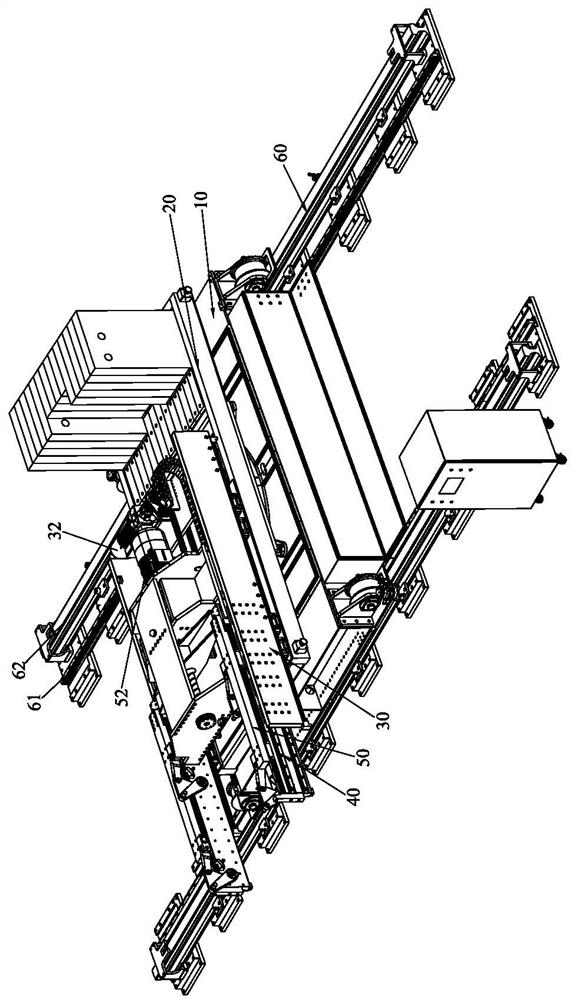

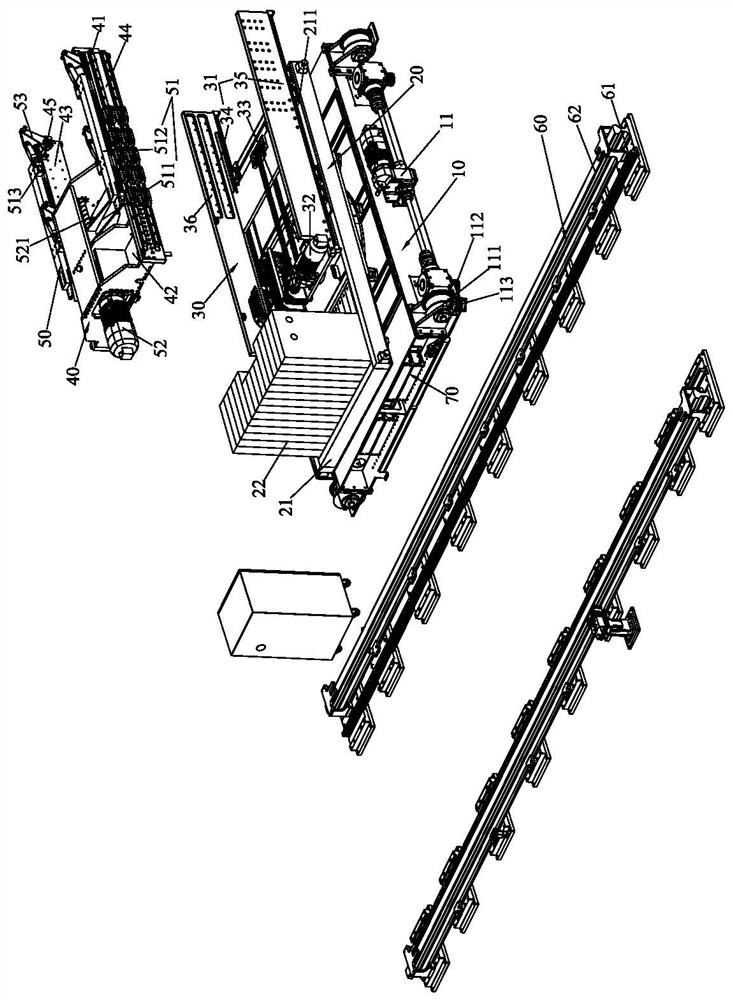

[0054] Please refer to Figure 1 to Figure 7 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises mobile base 10, material handling mechanism 20 and controller; Wherein:

[0055] The material handling mechanism 20 is arranged on the mobile base 10, and the material handling mechanism 20 includes a mounting base 21, a first lateral moving device 30 disposed on one end of the mounting base 21, and a first lateral moving device 30 disposed on the other end of the mounting base 21 for balancing The counterweight 22 of the first lateral movement device 30 (when carrying lighter materials, the weight of the equipment itself is sufficient to keep the overall balance of the equipment, and no counterweight 22 needs to be placed; when carrying heavier materials, it can be used as needed) Place the counterweight 22 to keep the overall balance of the equipment, and the weight of the counterweight 22 depends on the weight of the material); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com