Efficient and precise in-situ dressing method and device for cup-shaped arc grinding wheel

A circular arc and cup-shaped technology, which is applied to abrasive surface adjustment devices, manufacturing tools, parts of grinding machine tools, etc., can solve the problems of difficult to control the trimming accuracy, difficult to control the sub-surface defects of components processing, and low trimming efficiency. The effect of high-efficiency and high-precision in-situ dressing, removing hard particles, and lubricating hard particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

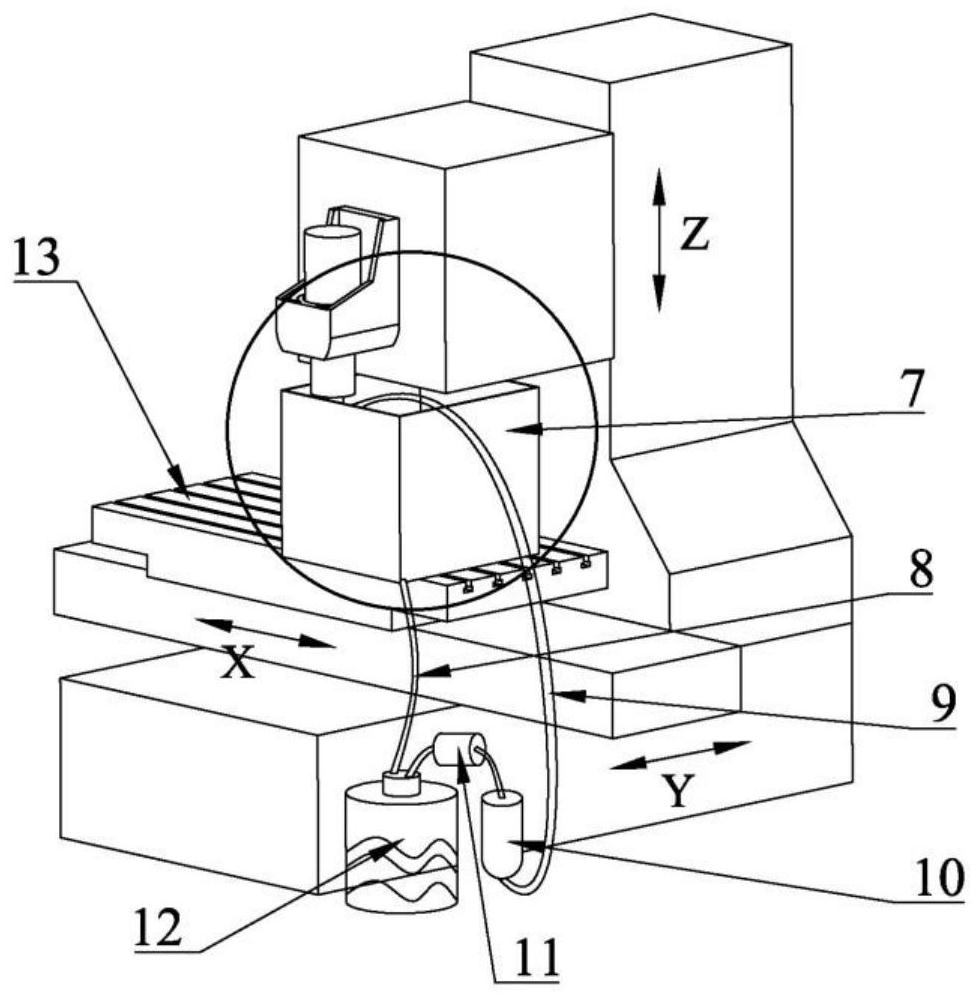

[0050] A high-efficiency and precise in-situ dressing method for a cup-shaped arc grinding wheel. The dressing steps are as follows:

[0051] S1: Radius measurement of plane dressing grinding wheel; among them, the three-axis linkage CNC machine tool can move in the directions of X-axis, Y-axis and Z-axis, and moving the X-axis or Y-axis of the machine tool is to move the machine tool table in the X- or Y-direction , moving the Z axis of the machine tool is to move the machine tool spindle along the Z direction;

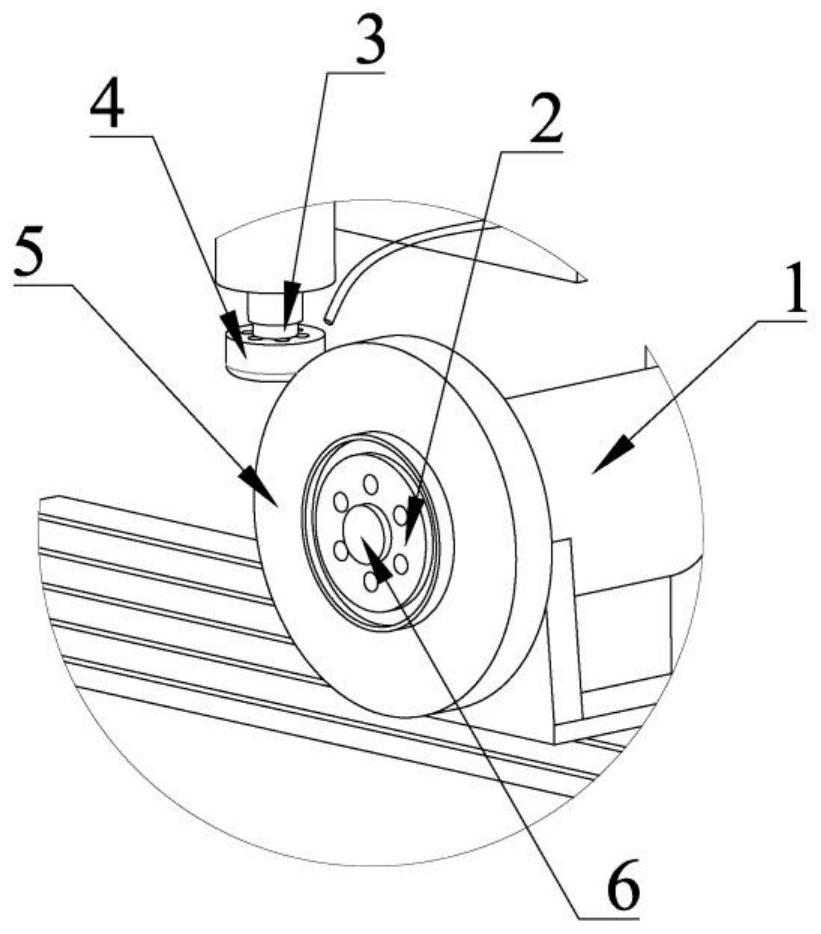

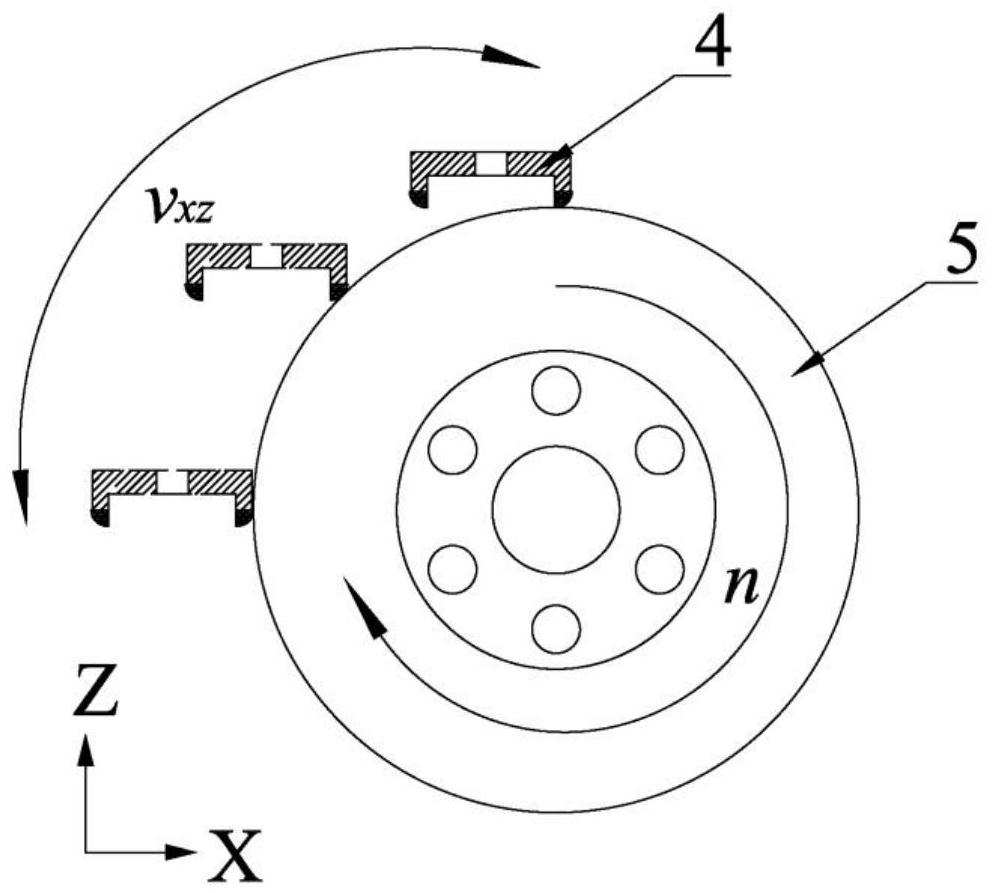

[0052] like Figure 5 As shown, the displacement sensor 14 is fixed on any position of the machine tool spindle 3, the 4 axes of the cup-shaped arc grinding wheel coincide with the 3 axes of the machine tool spindle, and the X-axis and Z-axis of the machine tool are moved by the hand wheel, and the displacement sensor 14 is moved to the plane dressing At the highest point on the circumference of grinding wheel 5, move the Z-axis of the machine tool to make the readi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com