Three-phase motor stator casting forming finish machining treatment process

A three-phase motor and casting molding technology, which is applied in the manufacture of tools, metal processing equipment, and stator/rotor body manufacturing, etc. It can solve the problems of poor stability of the clamping stator, inability to clean small parts of the stator, and slow finishing efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

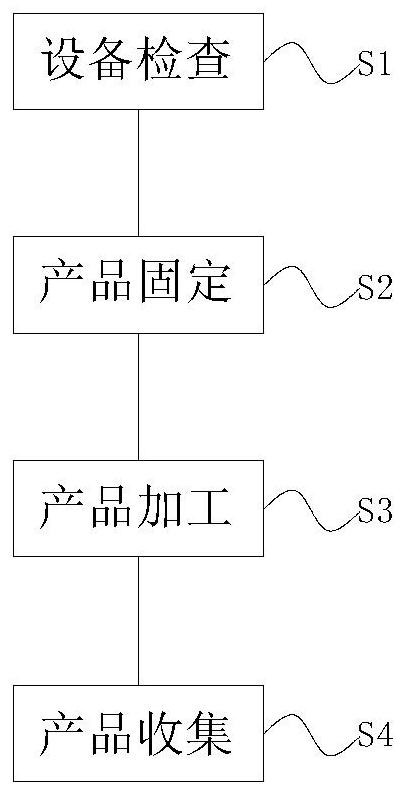

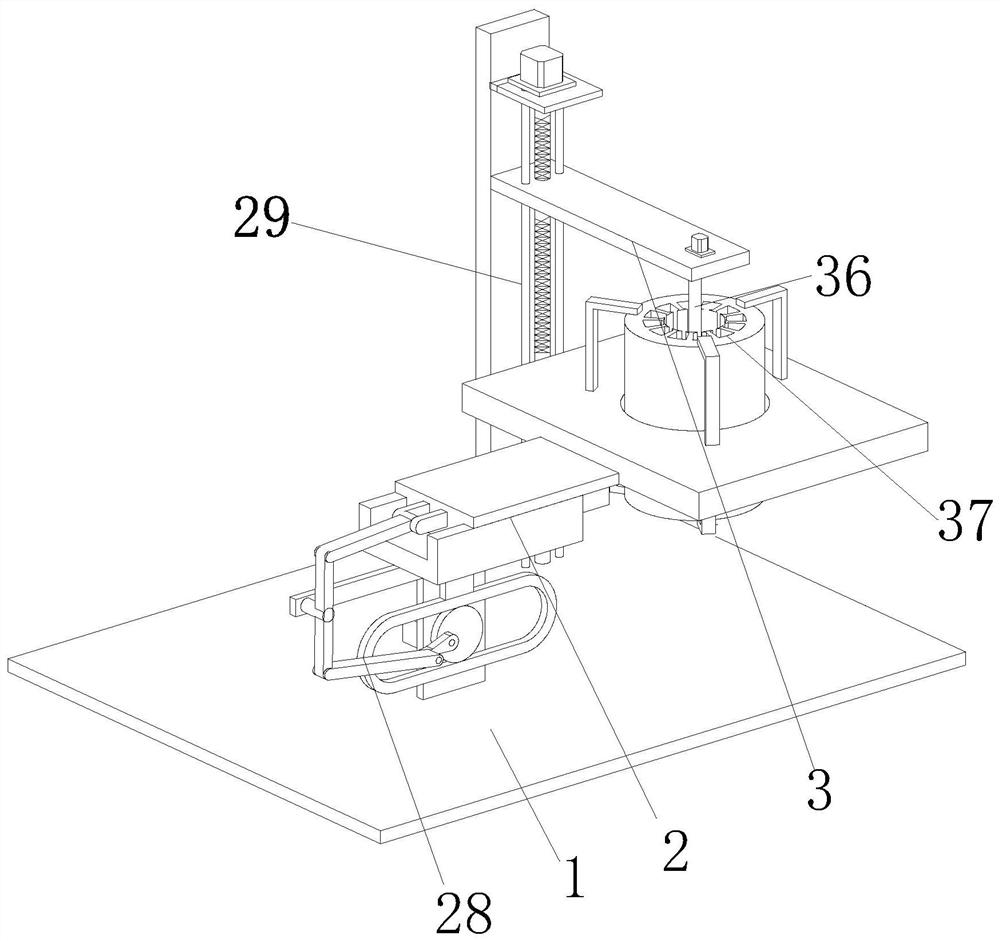

[0038] Such as Figure 1 to Figure 10 As shown, a three-phase motor stator casting molding finishing process, the three-phase motor stator casting molding finishing process adopts the following three-phase motor stator casting molding finishing equipment, the equipment includes a base plate 1, a shaking device 2 and a grinding Device 3, a shaking device 2 is fixedly installed on the base plate 1, and a grinding device 3 is arranged on the base plate 1; during specific work, the sand and gravel inside the special-shaped hole inside the stator of the three-phase motor are polished by the grinding device 3, and then the shaking device 2 Shake off some fine gravel.

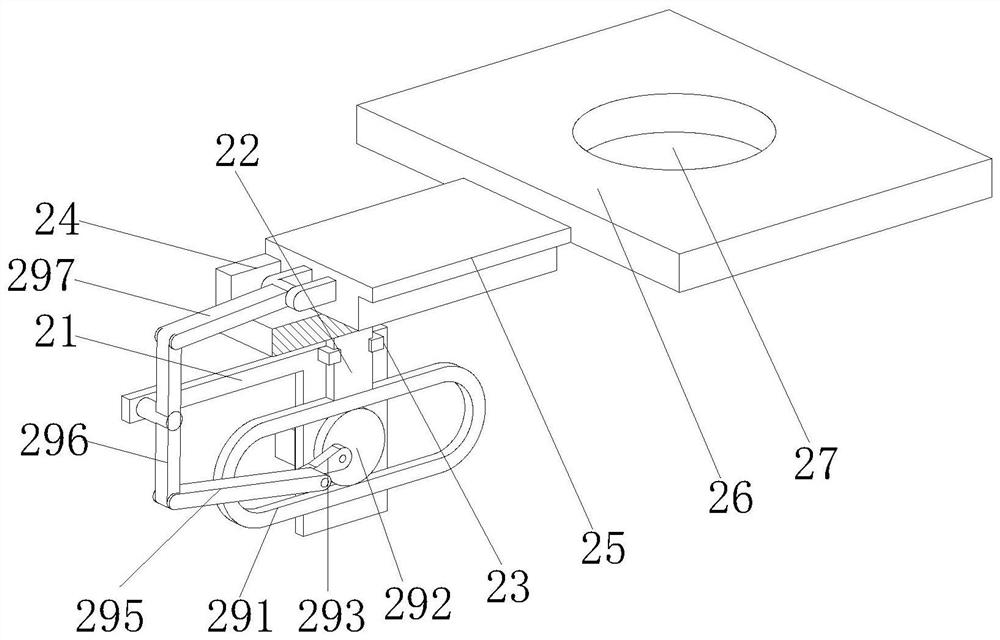

[0039] The shaking device 2 includes a vertical plate 21, a connecting plate 22, a lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com