Surface dust sticking equipment for PCB production

A PCB board and dust-sticking technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inflexible operation, time-consuming and labor-intensive, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

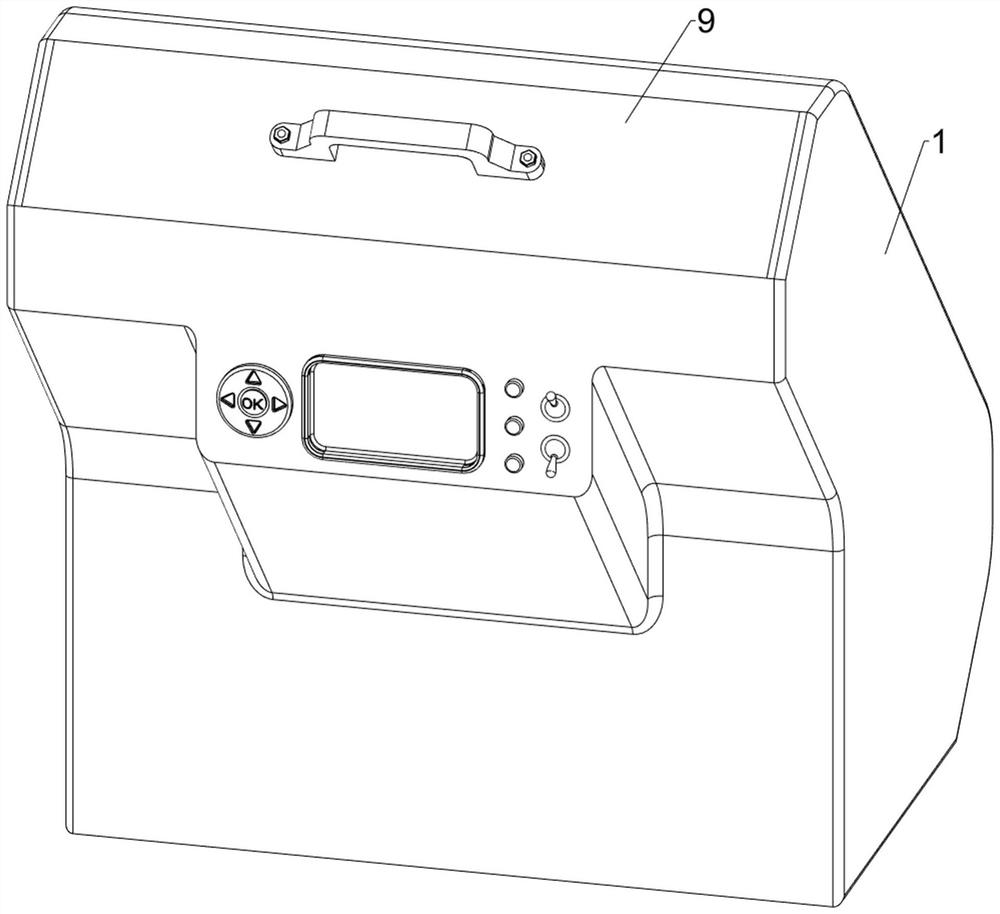

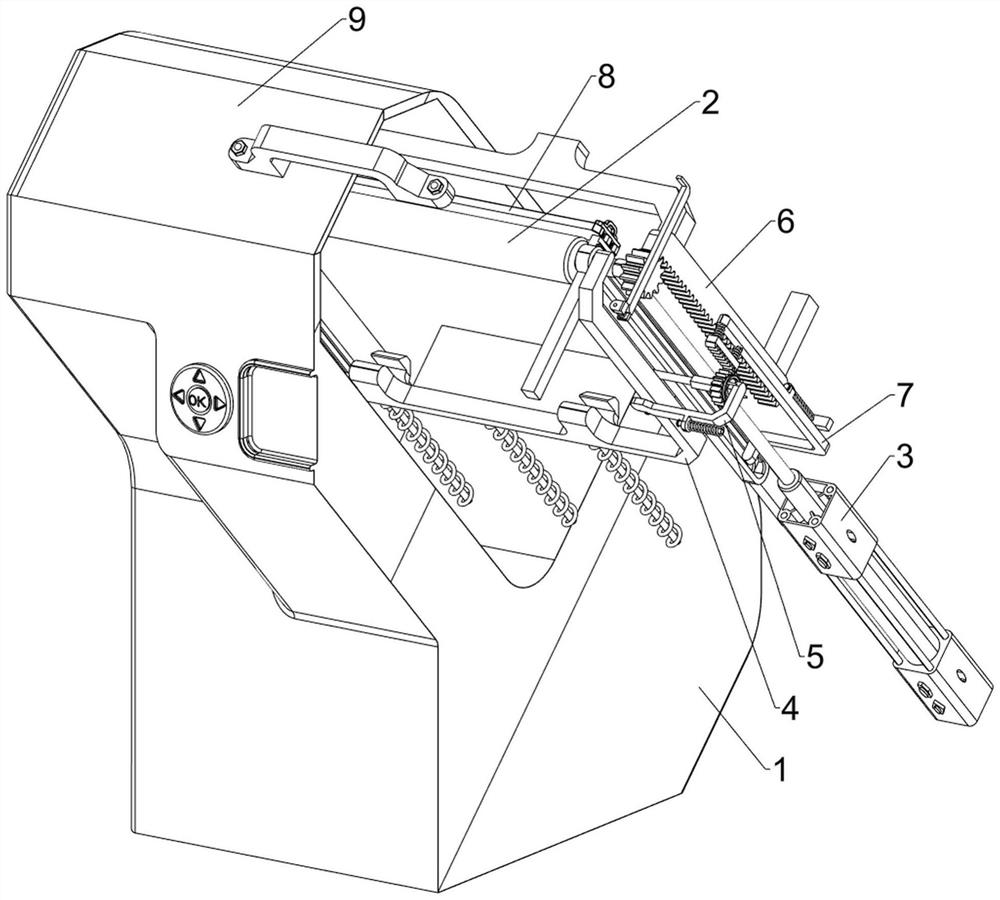

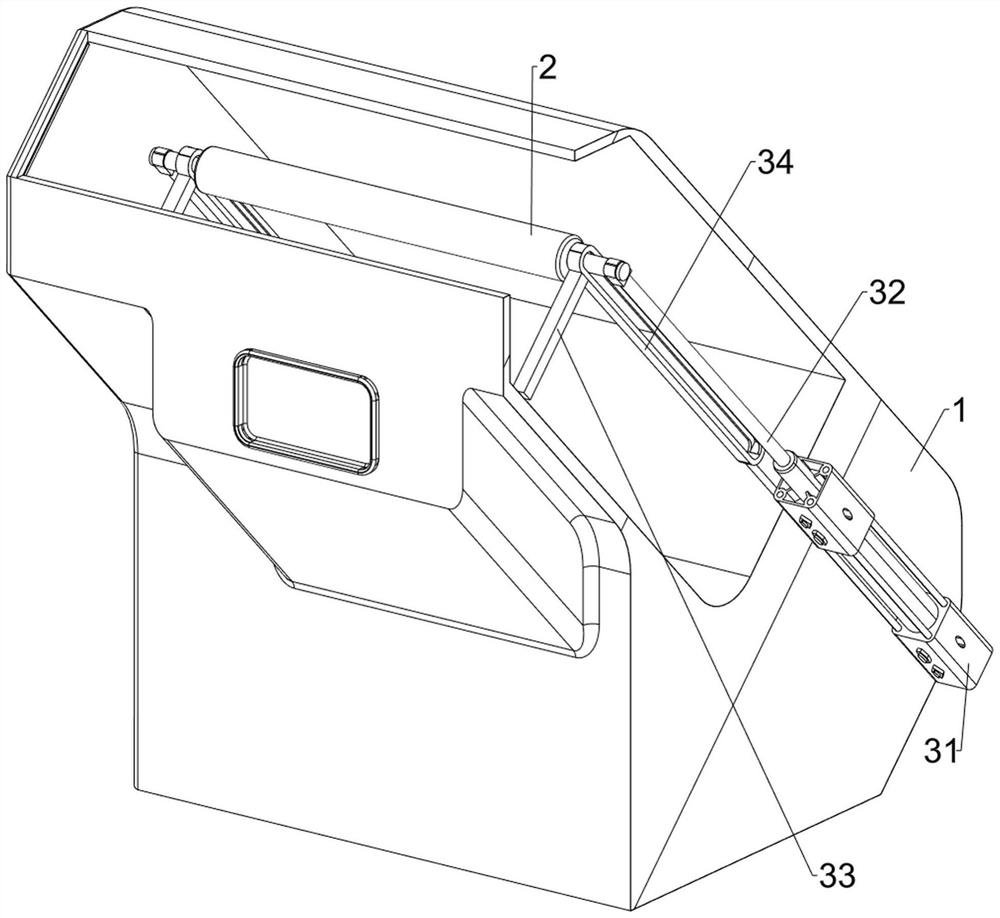

[0030] A kind of surface sticking dust equipment for PCB board production, such as Figure 1-Figure 5 As shown, it includes a casing 1, a sticky glue stick 2, a moving component 3, a placement component 4 and a clamping component 5, a moving component 3 is arranged inside the casing 1, and a sticky sticky glue stick 2 is arranged on the moving component 3 in a rotating manner. The moving component 3 is provided with a placing component 4 , and the placing component 4 is provided with a clamping component 5 .

[0031] First, people put the PCB board into the placement component 4 in the shell 1, start the moving component 3 to drive the sticky glue stick 2 to move downward, and at the same time, the moving component 3 cooperates with the clamping component 5, and the clamping component 5 clamps the PCB board. The dust-sticking glue stick 2 moves downward under the action of the moving component 3 to carry out the dust-sticking work on the PCB board, so as to achieve the effect ...

Embodiment 2

[0037] On the basis of Example 1, such as Figure 6-Figure 11 As shown, a rotating assembly 6 is also included. The rotating assembly 6 includes a second support rod 61, a spur rack 62 and a spur gear 63. The upper rear side of the housing 1 is provided with a second support rod 61. The front of the second support rod 61 Side left and right symmetry is provided with spur rack 62, sticky dust glue stick 2 is provided with spur gear 63 left and right symmetry, and spur gear 63 meshes with spur rack 62.

[0038] In order to prevent the sticky rubber stick 2 from rotating inflexibly on the push rod 32, when the cylinder 31 is activated and the push rod 32 and the sticky sticky stick 2 move downward, the spur gear 63 on the sticky stick 2 is driven to move downward. , under the action of the spur rack 62, the spur gear 63 and the sticky stick 2 automatically rotate to improve the effect of sticking dust on the surface of the PCB. When the cylinder 31 is closed, the push rod 32, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com