Demulsification, dehydration and separation method of emulsion

A separation method and emulsion technology, which is applied in the field of demulsification and dehydration separation of emulsions, and can solve problems such as low speed, increased difficulty, unfavorable droplet coalescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

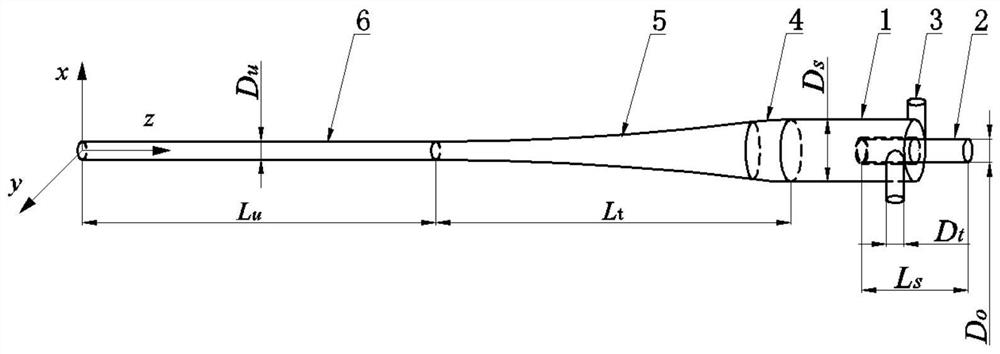

[0057] See Figure 2 - Figure 4 , An emulsion is broken-milk dehydrating separation method, including a cyclone, the cyclone comprising a swirl chamber with a cylindrical section and a bottom pipe with the swirl chamber, one end of the swirl chamber is closed and The inlet tube and an overflow tube coaxial with the swirl chamber are connected to the circumference of the inner wall of the swirl chamber, and the number of inlet tubes is two, two inlet tubes. The axis center of the swirl chamber is symmetrical.

[0058] The overflow tube is insulated through the closed end of the swirl chamber and in the inner end and the swirl chamber; the other end of the swirl chamber toward the bottom pipe and communicates with the bottom pipe through the coaxial smooth transition pipe section; the wall of the swirl chamber And overflow tubes are electrically conductive materials.

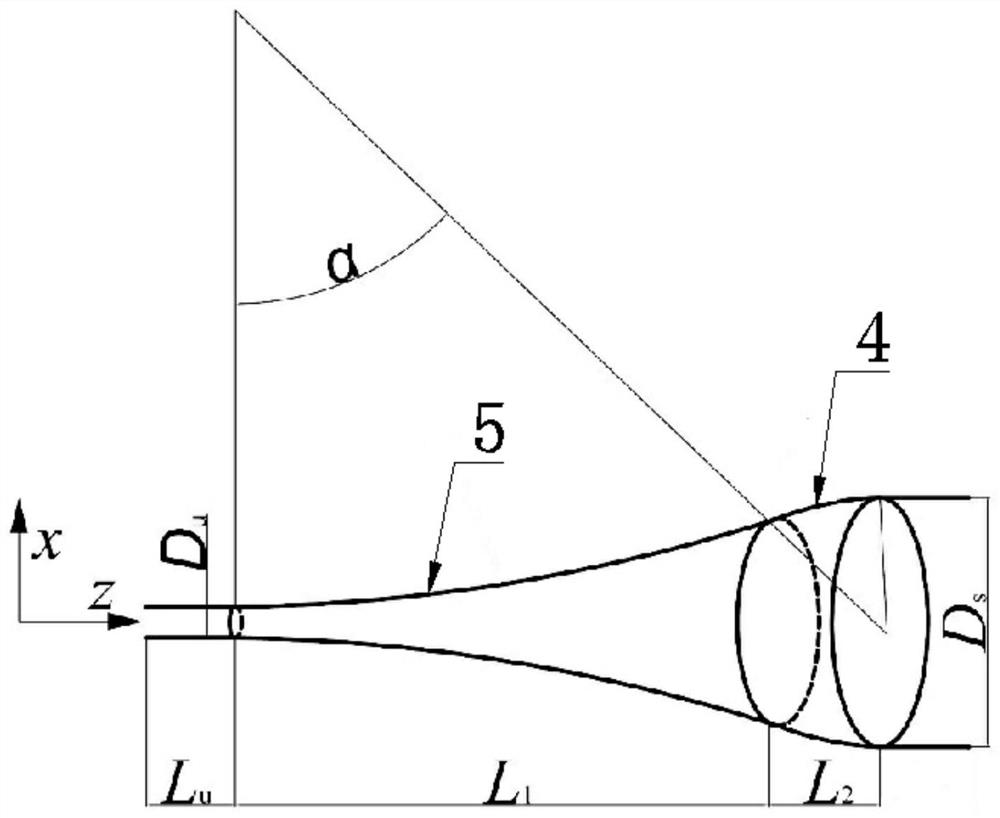

[0059] On the axial cross section of the swirl chamber, the inner wall of the smooth transition tube includes a conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com