A kind of high-efficiency fire extinguishing agent and fire safety fire extinguishing process

A fire extinguishing agent and safe technology, which is applied in the field of high-efficiency fire extinguishing agent and fire safety fire extinguishing technology, can solve the problems that it is difficult to effectively suppress the resurgence of lithium battery fires, lack of cooling and fire extinguishing, etc., achieve excellent cooling effect, take into account the cooling ability, prevent The effect of resurgence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

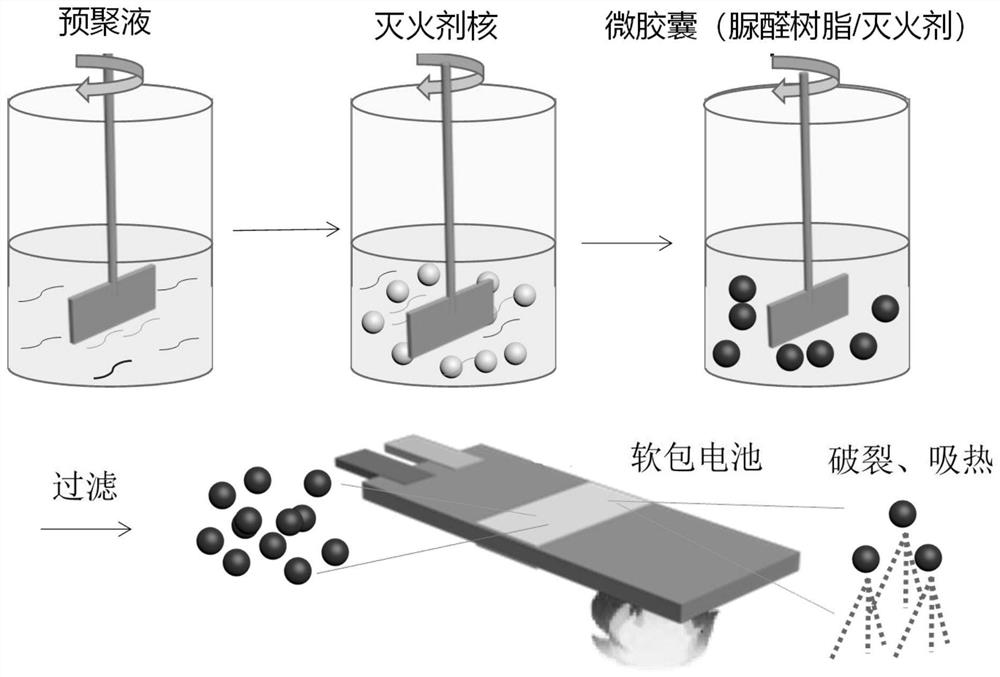

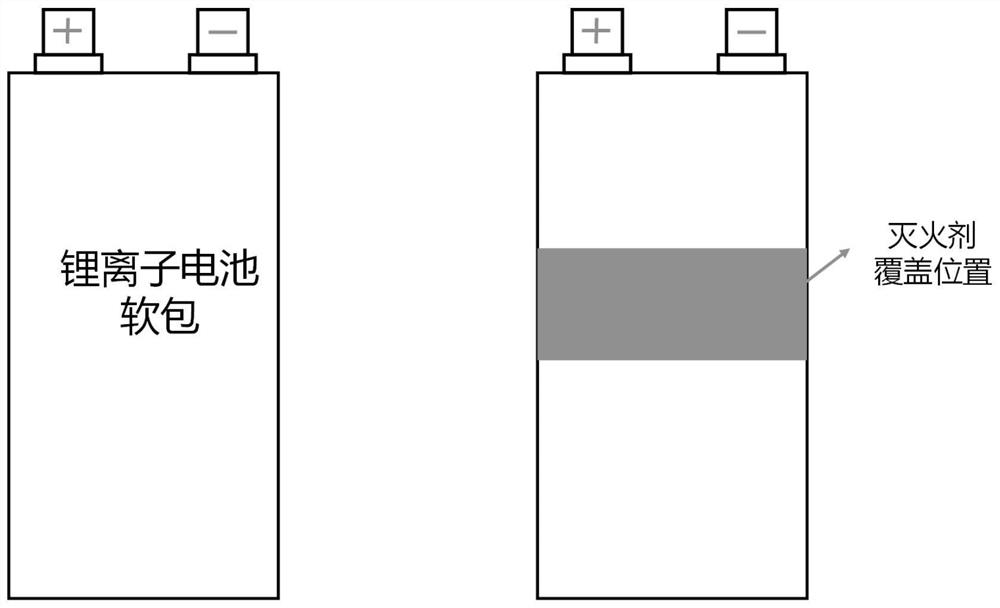

[0044] This embodiment provides a high-efficiency fire extinguishing agent and fire safety fire extinguishing process, the schematic diagram of its process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0045] S1, preparation of melamine urea-formaldehyde resin prepolymer

[0046] Add 7.76g melamine, 7.40g urea, 29.98g formaldehyde solution (concentration is 37wt%) and 30g distilled water in the there-necked flask, adjust its pH to 8.5~9.0 with anhydrous sodium carbonate, then, heat the there-necked flask in a water bath, with The temperature of the water bath was gradually increased from 30°C to 70°C at a rate of 2.5°C / min, and after stirring for 1 hour, the temperature was rapidly lowered to below 40°C by adding ice water. Then it was diluted with 375 g of distilled water to obtain a melamine urea-formaldehyde resin (MUF) prepolymer with a concentration of 10 wt%.

[0047] S2, preparation of high-efficiency fire extinguishing agent

...

Embodiment 2~9 and comparative example 1~3

[0058] Embodiments 2 to 9 and comparative examples 1 to 3 respectively provide a high-efficiency fire extinguishing agent and fire safety fire extinguishing process. Compared with Example 1, the difference is that some preparation parameters in steps S1 and S2 are adjusted, and each implementation The corresponding parameters of the example and the comparative example are shown in Table 2, and the rest of the steps and parameters are consistent with Example 1, and will not be repeated here.

[0059] Table 2 embodiment 2~9 and the relative process parameter of comparative example 1~3

[0060]

[0061]

[0062] Prepare the corresponding fire extinguishing agent according to the process parameters provided in Examples 2-9 and Comparative Examples 1-3, and load it on the outer surface of the aluminum-plastic film of the lithium-ion battery according to the method of step S3 in Example 1, and then perform each The fire extinguishing effect of the example and the comparative e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com