Automatic preheating control system during cold start of fuel cell system

A technology of fuel cell system and preheating control, which is applied in the direction of battery/fuel cell control device, fuel cell heat exchange, fuel cell, etc. Problems such as damage to the battery stack structure, etc., to achieve the effect of strong practicability, stable and uniform heating, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

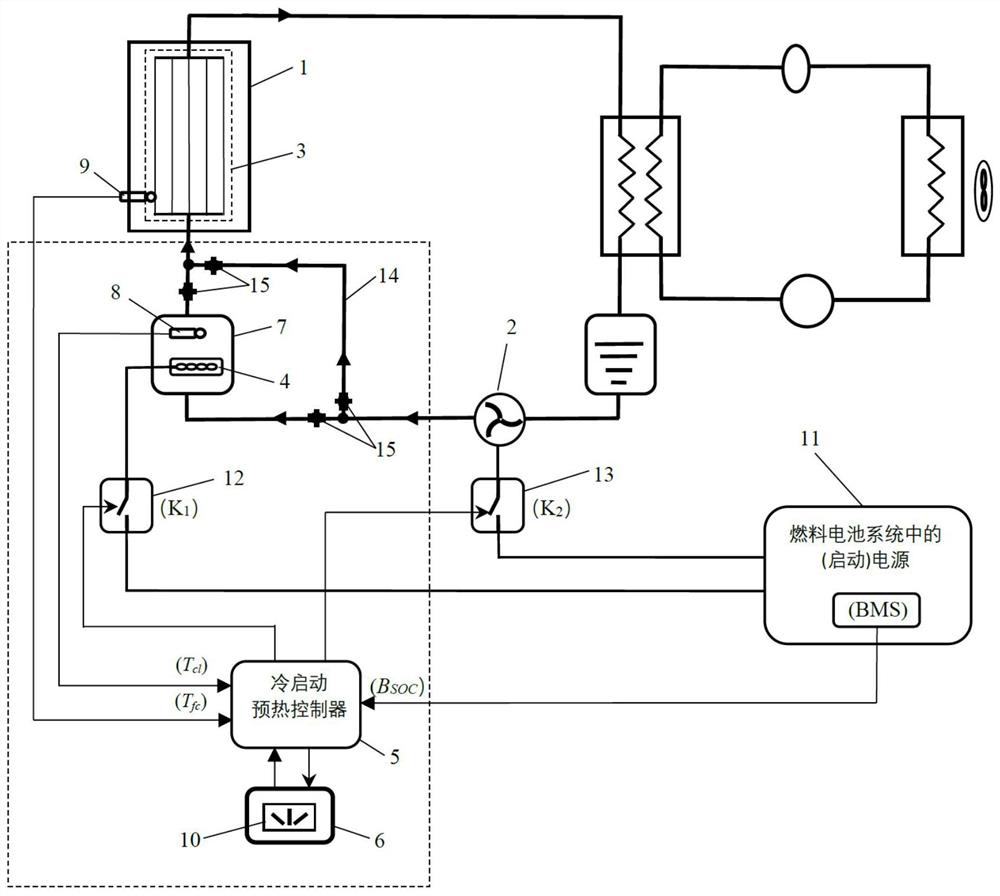

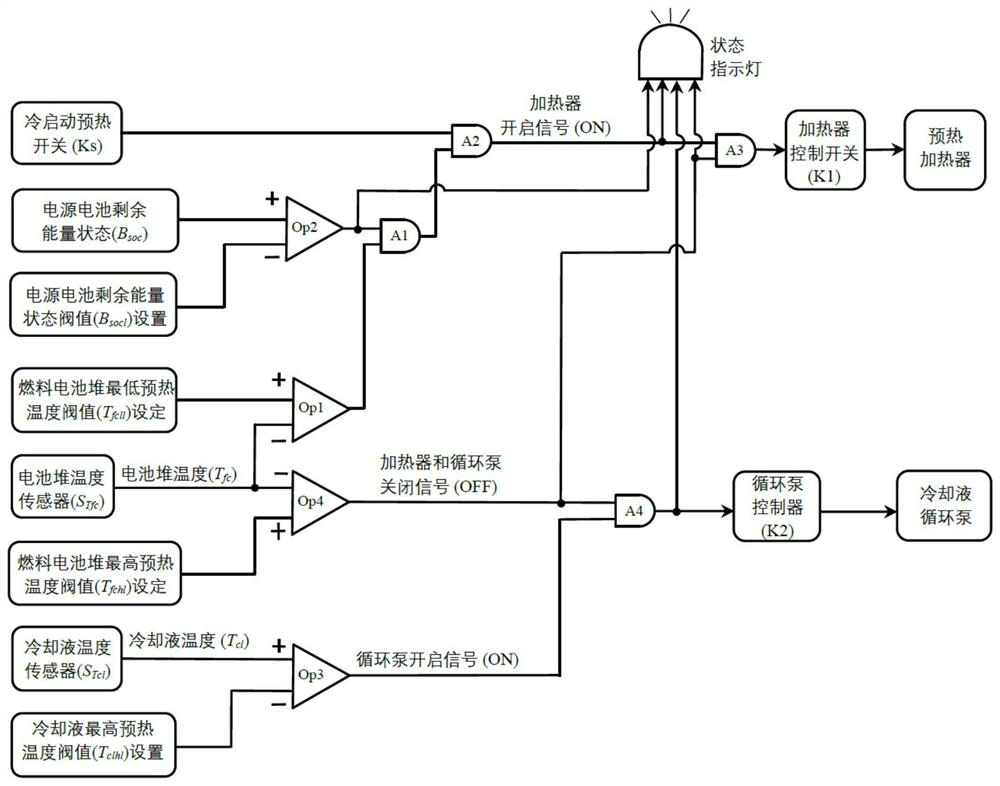

[0031] In order to solve the technical problem that the low temperature has adverse effects on the performance and life of the fuel cell stack when the fuel cell is cold-started under extremely cold conditions, usually, many fuel cell manufacturers directly add external heating to the outside of the fuel cell stack. When it needs to be warmed up, turn on the heater to heat the fuel cell stack. Since this external heater is heated from the outside of the fuel cell stack, it takes time for the heat to transfer from the outside to the inside of the fuel cell stack, and the heating to the inside of the fuel cell stack is uneven. Thereby it has disadvantages such as lower efficiency, longer heating time, and difficulty in accurately controlling the heating temperature.

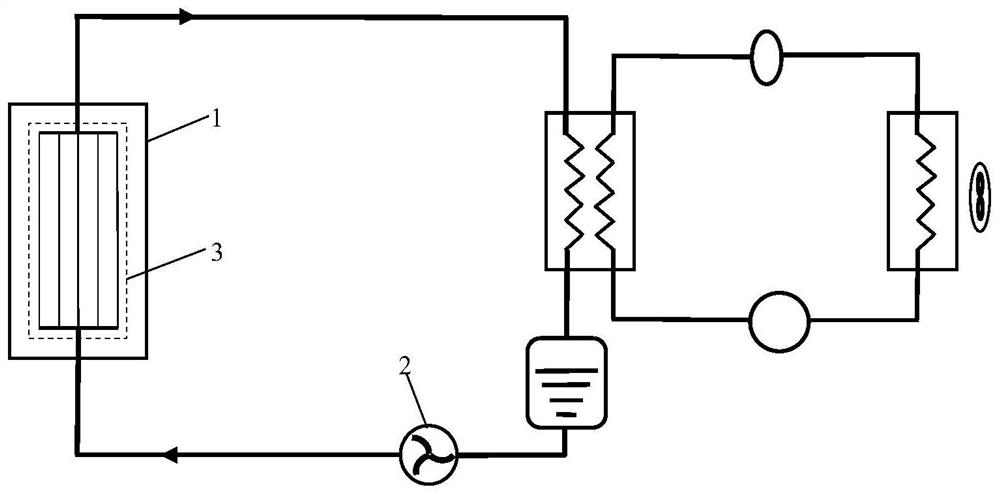

[0032] For fuel cell systems with large capacity, liquid cooling is generally used, and the basic structure of the liquid cooling system is as follows: figure 1 As shown, it is composed of the liquid cooling circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com