Gas leakage detection system and method

A gas leak detection and detector technology, which is applied in the detection field, can solve problems such as low detection accuracy and gas leakage, and achieve the effects of enhancing light intensity, reducing detection errors, and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

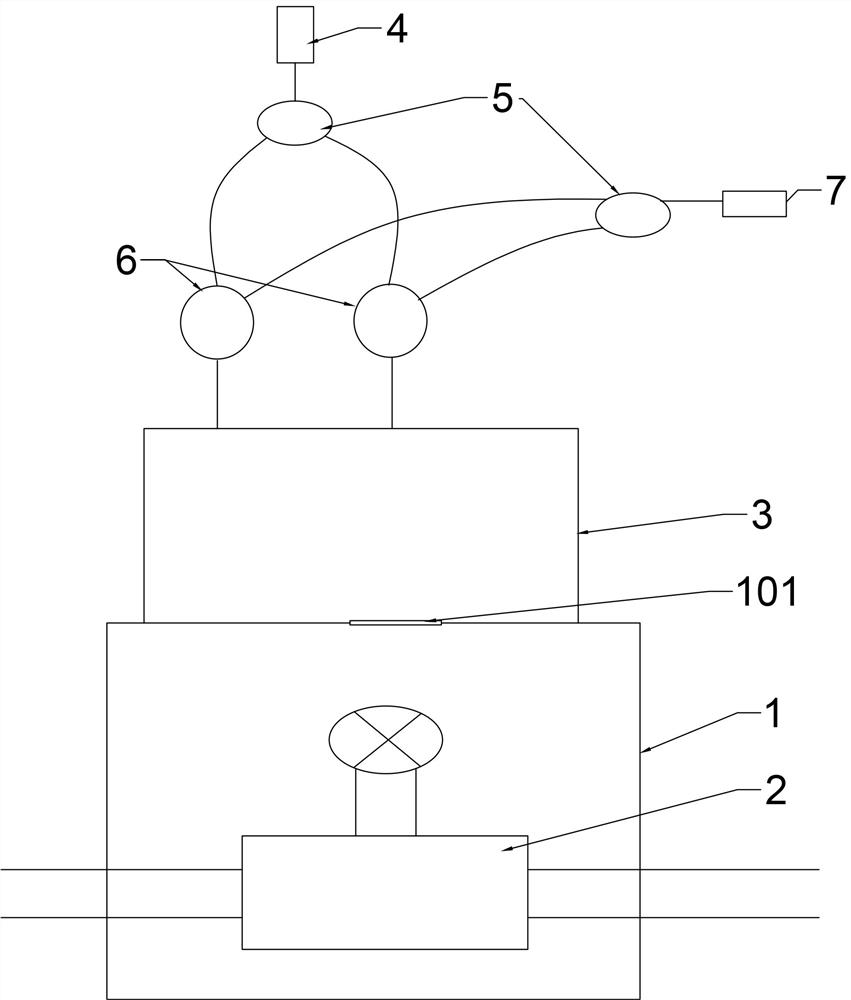

[0032] Such as figure 1 As shown, a gas leak detection system includes a light source 4 capable of emitting light and a detector 8 for detecting light performance. The light source 4 can be a laser, and it only needs to ensure that the light emitted by the light source is stable and not easily affected by other environmental factors. In addition, it also includes a sealed chamber 1, which is sealed outside the place to be measured 2. The upper end surface of the sealed chamber 1 has a small hole, and a deformation device 101 is installed on the hole. The deformation device 101 seals the small hole by bonding, and the sealing method is not limited to bonding, it only needs to ensure that the entire sealing chamber 1 is sealed; the deformation device 101 can use an elastic diaphragm, but it is not limited to this, and can be other materials that are suitable for pressure changes. deformable material, and the sealing chamber 1 is made of rigid material, so as to ensure that the s...

Embodiment 2

[0037] A gas leakage detection system described in Embodiment 1 is used to detect the gas leakage at the place to be tested, and a valve interface of a gas transmission pipeline is selected as the place to be tested. The light intensity value as the prestored light intensity reference value; then collect the light intensity detection value output by the detector 8 at any moment to be measured, compare the collected light intensity detection value with the prestored light intensity reference value, if two If they are not consistent, it indicates that there is an air leak at the test site 2; otherwise, it indicates that there is no air leak at the test site 2.

[0038] working principle:

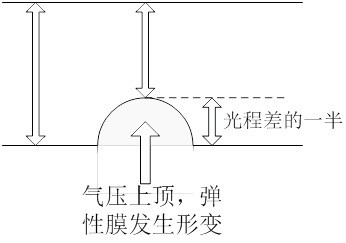

[0039] Such as figure 2 As shown, the deformation device 101 uses an elastic diaphragm; the light source 4 uses a laser; the optical signal splitting element and the optical signal combining element use a coupler; the place to be measured 2 is a gas pipeline valve interface.

[0040]When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com